Model test device and method for studying thermal consolidation effect of soft clay

A model test device, soft clay technology, applied in the direction of measuring device, using a stable tension/pressure test material strength, instruments, etc., to achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

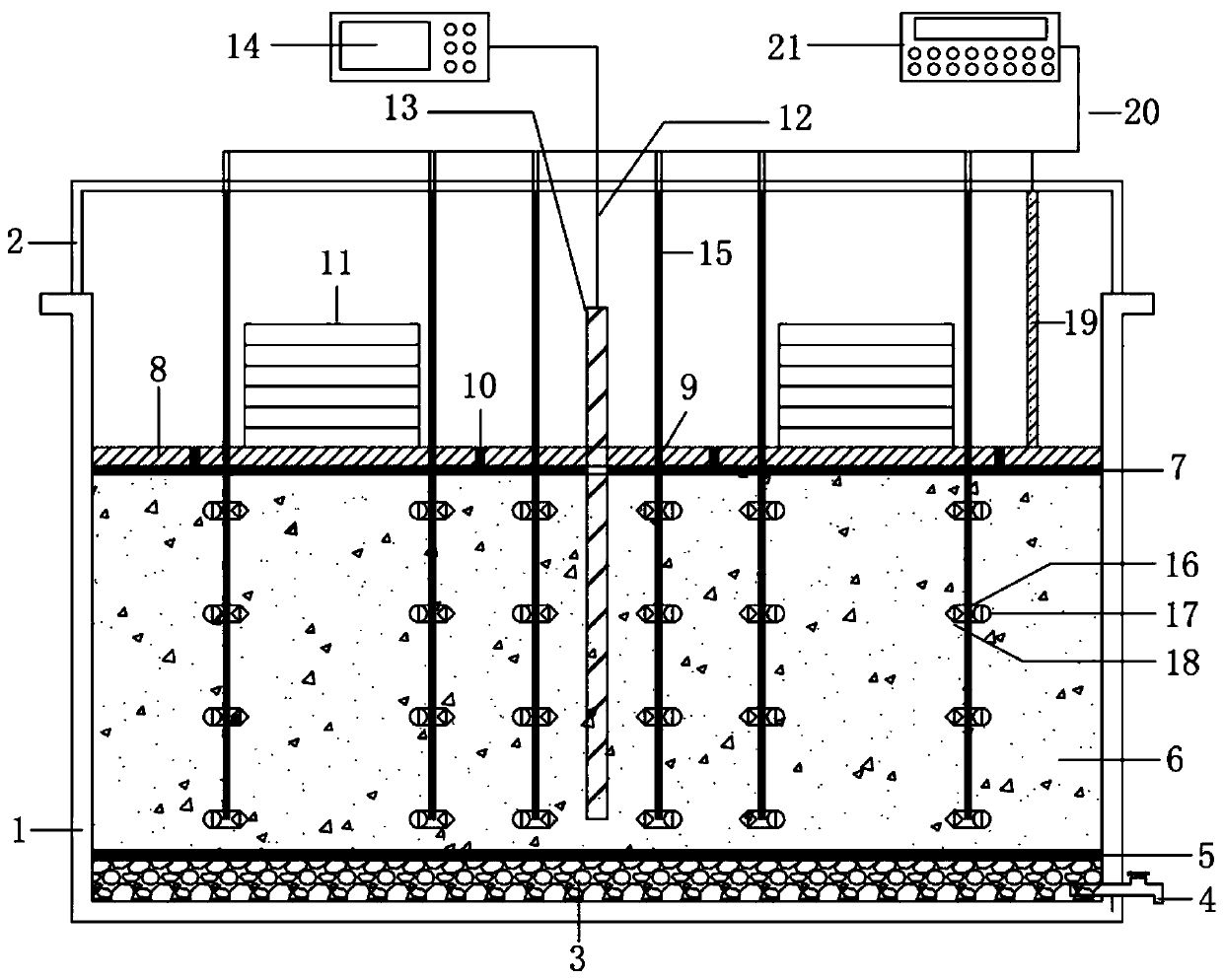

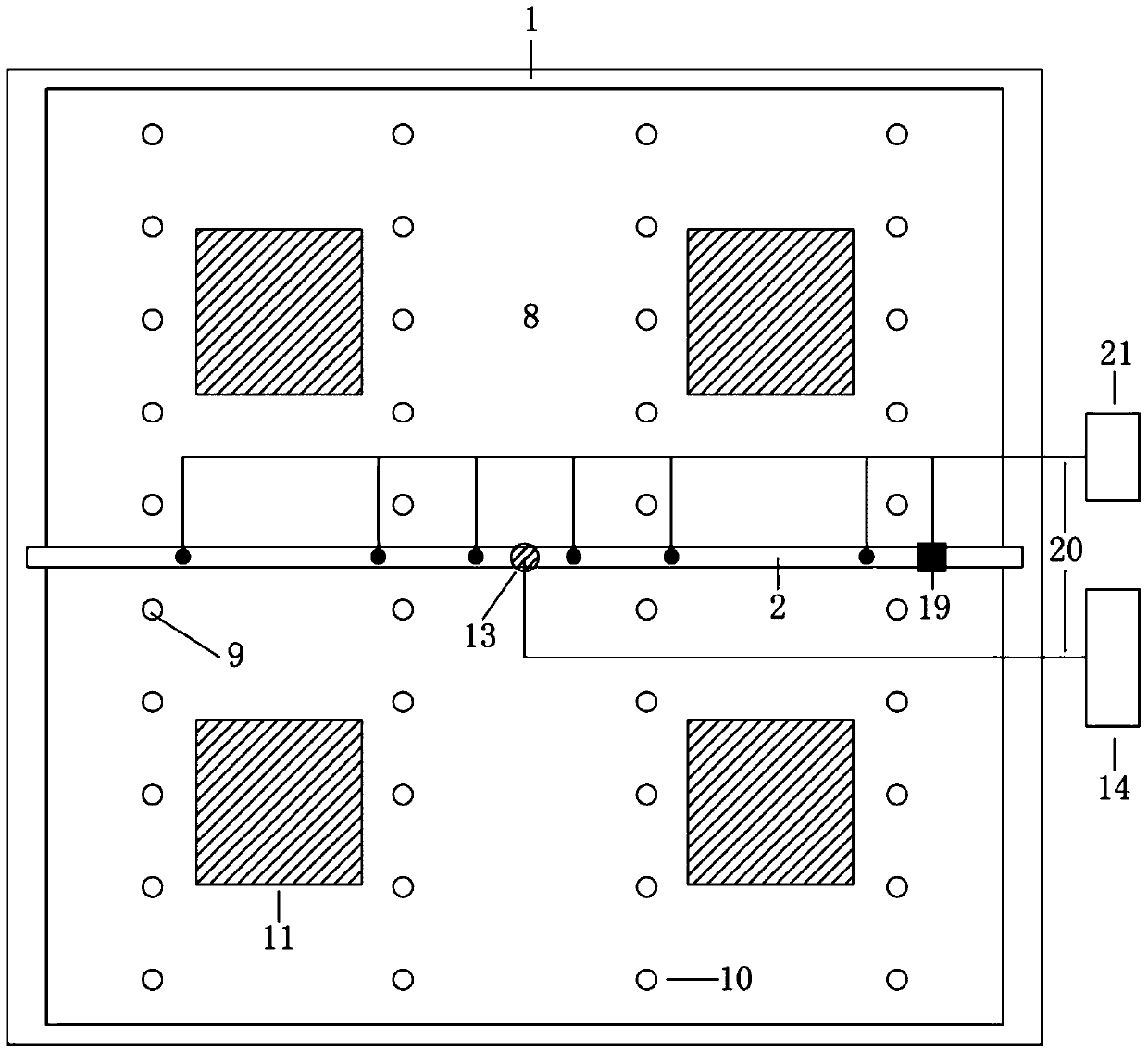

[0058] Such as figure 1 , figure 2 As shown, the present invention provides a model test device for studying the thermal consolidation effect of soft clay. Clay 6, top layer geotextile 7, loading plate 8, reserved hole 9 of loading plate, drainage hole 10, loading block 11, steel cable 12, heater 13, temperature controller 14, fixed steel wire 15, sensor fixing box 16, Pore pressure sensor 17, temperature sensor 18, displacement sensor 19, sensor data line 20, data collector 21.

[0059] The model tank 1 is placed horizontally in the test area. The model tank 1 is a cuboid and welded by steel plates; the gravel drainage layer 3 is evenly laid on the bottom of the model tank 1, and a drain valve 4 is installed on the side of the model tank 1. The geotextile 5 is laid on the leveled sand and gravel drainage layer 3, which can be used as the bottom drainage layer; during the test, the side wall of the model tank 1 is coated with silicone grease, and the soft clay 6 studied i...

Embodiment 2

[0061] Step 1, test preparation:

[0062] Step 101, smear silicone grease on the inner wall of the model tank, pour the soft clay slurry for the test that has been stirred, and open the drain valve;

[0063] Step 102, after standing still for one day, extract the excess water precipitated from the top of the mud, lay the top layer of geotextile, and hoist it into the loading plate.

[0064] Step 103, fasten the steel frame to the model tank with bolts, apply lubricating silicone grease to the heater, and at the same time put the heater into the soft clay mud through the reserved hole of the loading plate, connect the heater to the steel cable and pass it through Reserved holes on the steel frame, hanging on the steel frame;

[0065] Step 104, fix the temperature sensor and pore pressure sensor to the sensor fixing box, apply lubricating silicone grease to the fixing steel wire connected to the sensor fixing box, and put the fixing steel wire through the reserved hole of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap