Low-temperature solidified sand and preparation method thereof

A technology of consolidating sand and low temperature, applied in the direction of chemical instruments and methods, drilling composition, etc., can solve the problems of oil (gas) well project scrapping, difficult repair, casing staggered breaking and collapsing, etc., to improve the reaction Speed and consolidation strength, increase product shelf life, and avoid the effect of flowback throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

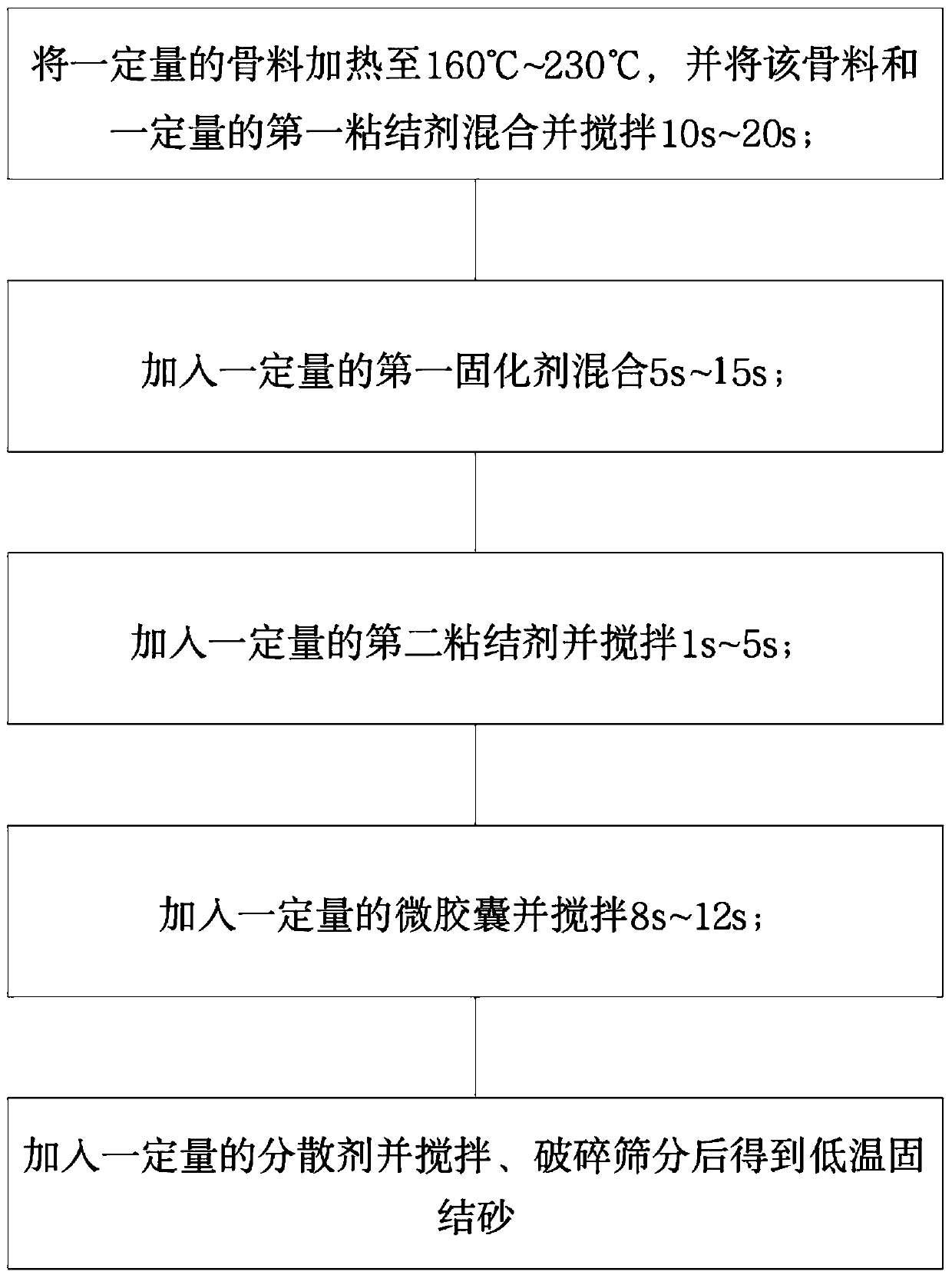

[0021] like figure 1 As shown, the first aspect of the present invention provides a method for preparing low-temperature consolidated sand, comprising: heating a certain amount of aggregate to 160°C to 230°C, and combining the aggregate with a certain amount of first bonding After that, add a certain amount of the first curing agent and mix for 5s to 15s, then add a certain amount of the second binder and stir for 1s to 5s; after that, add a certain amount of microcapsules and stir for 8s ~12s; after that, add a certain amount of dispersant and stir, crush and sieve to obtain low-temperature consolidated sand. Specifically, the mass ratio of aggregate, first binder, first curing agent, second binder, microcapsules and dispersant in the above preparation process is 800-1200:10-50:1-8:15 ~30:3~6:0.5~1.5.

[0022] It should be noted that the low-temperature consolidated sand obtained in the present invention is loose particles, which are injected underground, and the microcapsu...

Embodiment 1

[0025] like figure 1 As mentioned above, this embodiment provides a method for preparing low-temperature consolidated sand, which specifically includes the following steps:

[0026] First, weigh each material used in the preparation process according to the following mass ratio, specifically, the mass of aggregate, first binder, first curing agent, second binder, microcapsules and dispersant The ratio is 1000:10-50:1-8:15-30:3-6:1.

[0027] Add corresponding mass of aggregate according to the above mass ratio and heat to 160°C-230°C, mix the aggregate and corresponding mass of the first binder and stir for 10s-20s.

[0028] It should be noted that the aggregate in this embodiment can be quartz sand, ceramsite, etc., and the first binder can be bisphenol A epoxy resin. The same type of epoxy resin can be used according to their viscosity and epoxy value. Different, its performance and use will be different, therefore, this embodiment selects the epoxy value range of bisphenol...

Embodiment 2

[0041] In this example, the properties of the low-temperature consolidated sand prepared in Example 1 above are tested. The specific detection method is: add water and stir the low-temperature consolidated sand particles in Example 1, put them in a mold to prepare a sample block, then put it in a water bath for 24 hours to demould, and then measure its compressive strength and permeability. Specifically, the results show that the low-temperature consolidated sand sample block obtained by the present invention has a breakage rate of 1.15% against 52 MPa, an unconfined compressive strength of 15.1 MPa, and a sample block permeability of 156 μm 2 . From the above test results, it can be seen that the low-temperature consolidated sand provided by the present invention has fast curing speed, high strength, and short curing time, which can improve the production efficiency of oil wells, and has good permeability, and has little impact on the productivity of oil wells after sand cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com