A guide roller for a tower crane standard section

A technology of guide rollers and standard joints, which is applied in cranes, transportation and packaging, etc., can solve the problems of collision standard joints and unfavorable installation standard joints, and achieve the effect of avoiding collisions and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

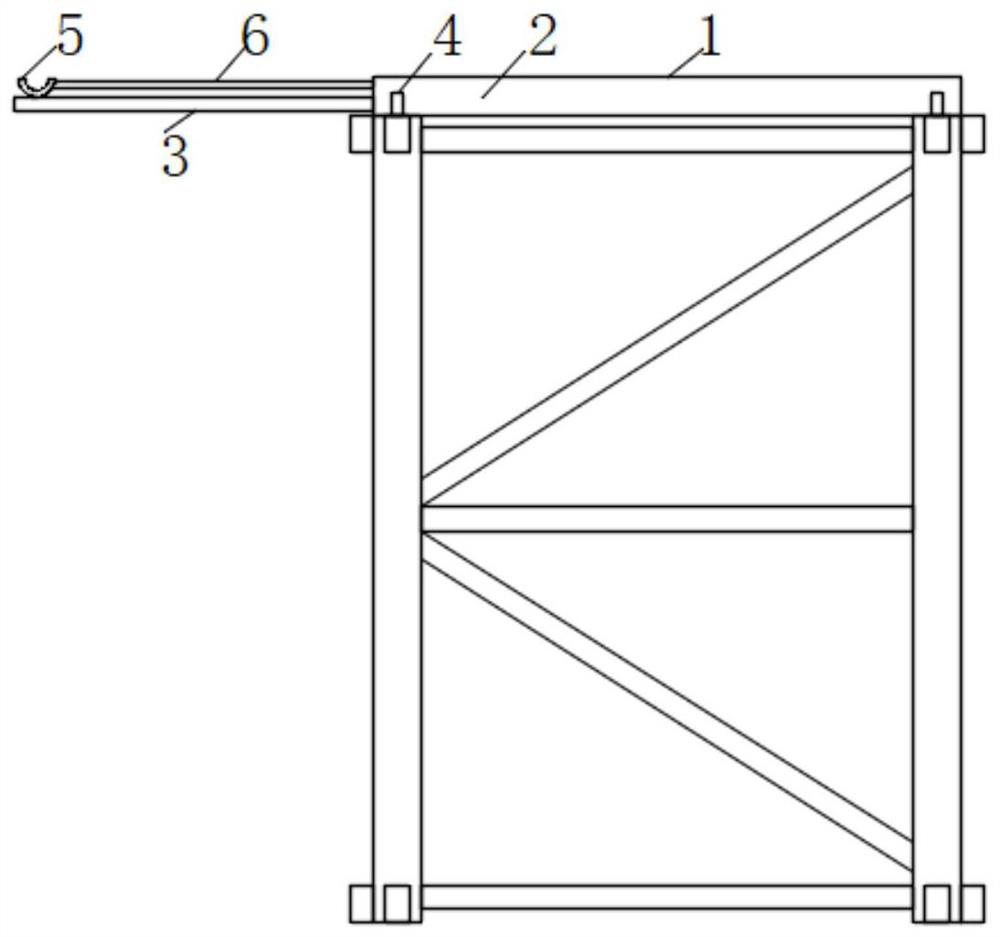

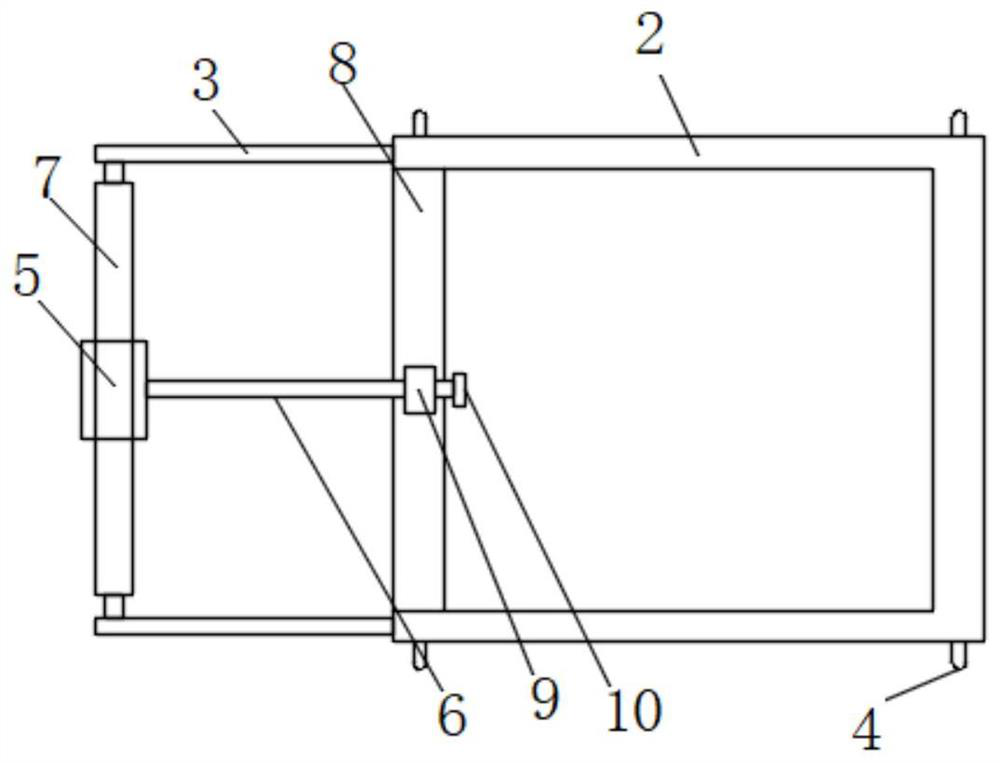

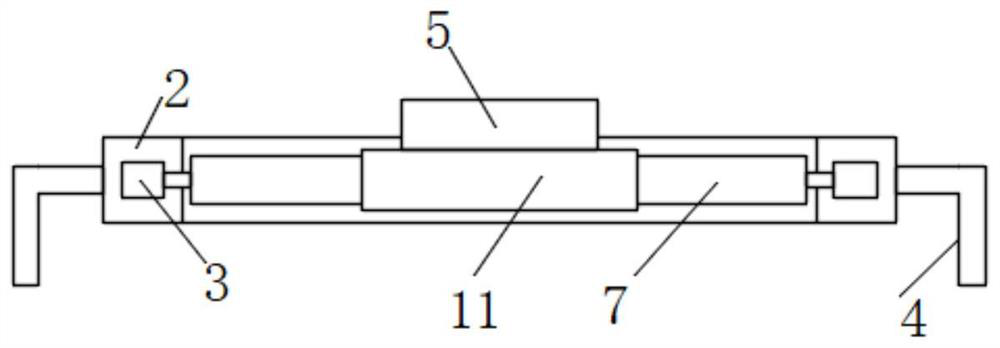

[0022] see Figure 1 to Figure 5 , the present invention provides a technical solution: a guide roller for a tower crane standard section, including a roller frame 1, the roller frame 1 includes a frame 2, a sliding beam 3, and a rotating roller 7, two sliding beams 3 are parallel and are respectively located on the frame 2 The side of the frame 2 is symmetrically provided with a slider 13, the inside of the sliding beam 3 is provided with a round block 12, the outer side of the roller 7 is provided with a drum 11, and the surface of the drum 11 is provided with a limit ring 5, and the frame 2 Connecting beams 8 are arranged between opposite surfaces, and positioning rods 4 are distributed at the four corners of the frame 2 . The surface of the connecting beams 8 is provided with a positioning mechanism 6 . The positioning mechanism 6 includes a fixed ring 9 and a connecting rod 10 .

[0023] In this embodiment, the frame 2 is a "U"-shaped structure, and the opposite surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com