Aluminum alloy shelf

A storage rack and aluminum alloy technology, which is applied in the field of daily life items placement, aluminum alloy storage racks, can solve the problems of unsatisfactory use, reduce the number of items placed, limited space and position, etc., and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further describe the present invention, a specific embodiment of an aluminum alloy storage rack is further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

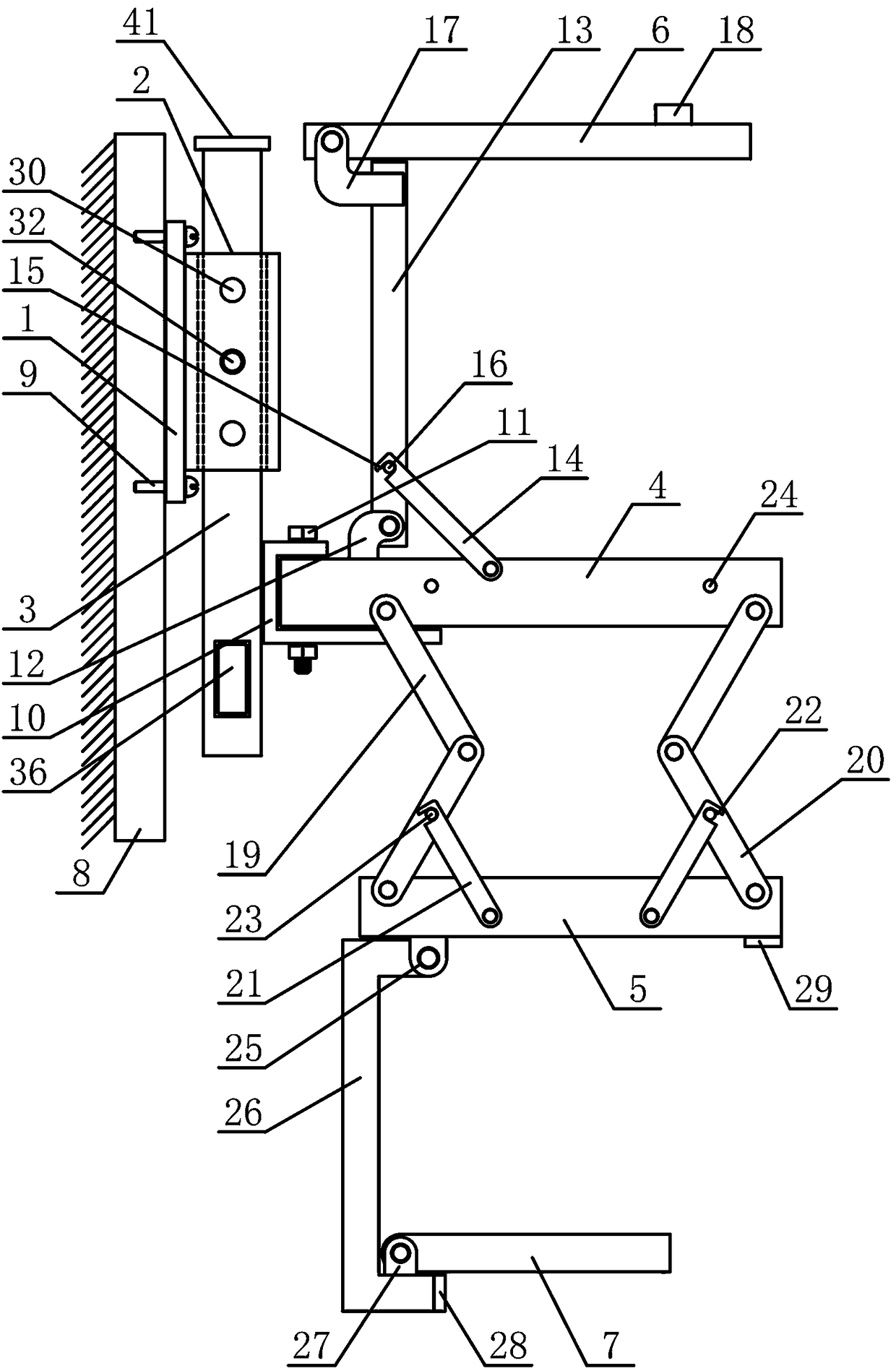

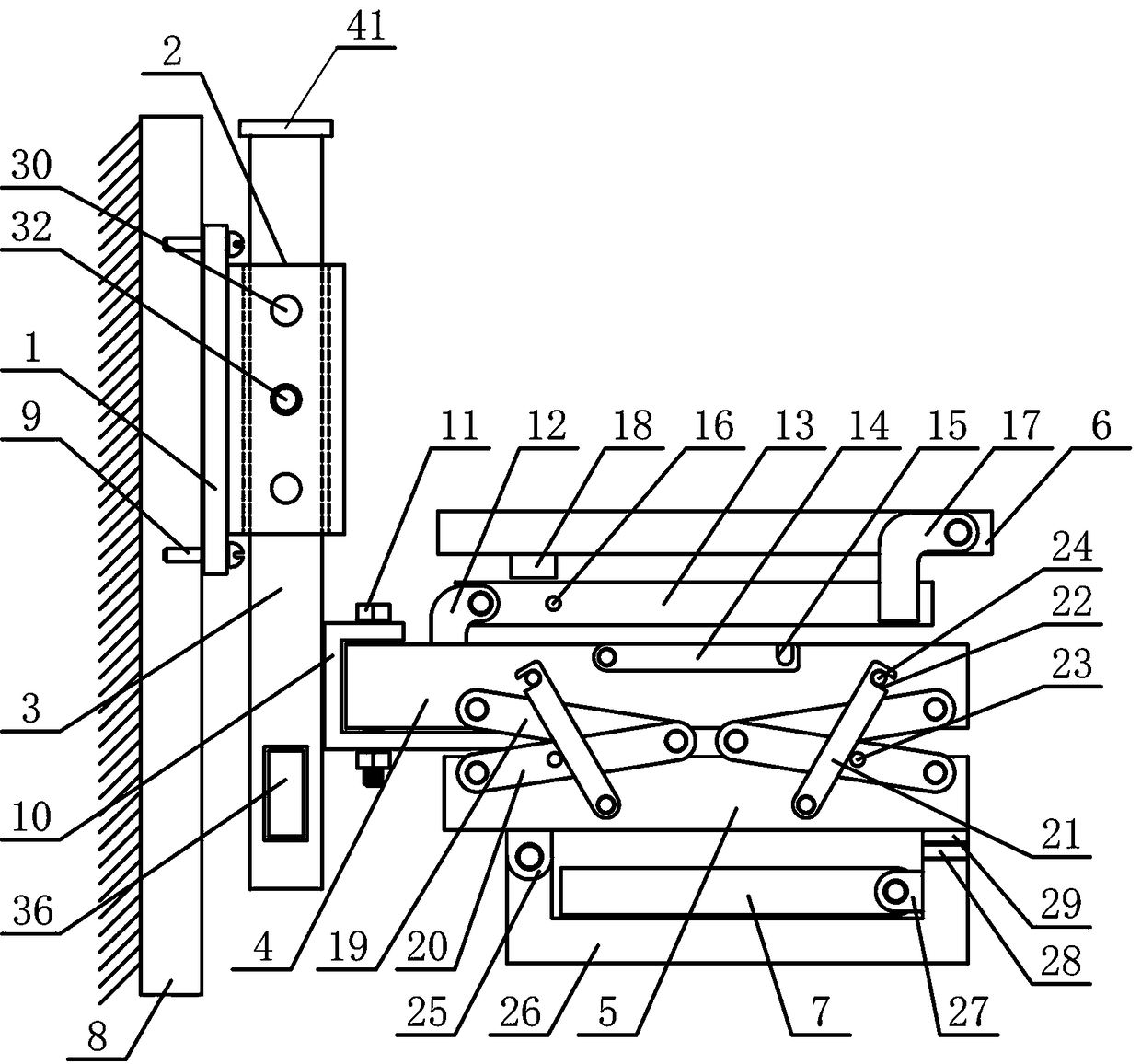

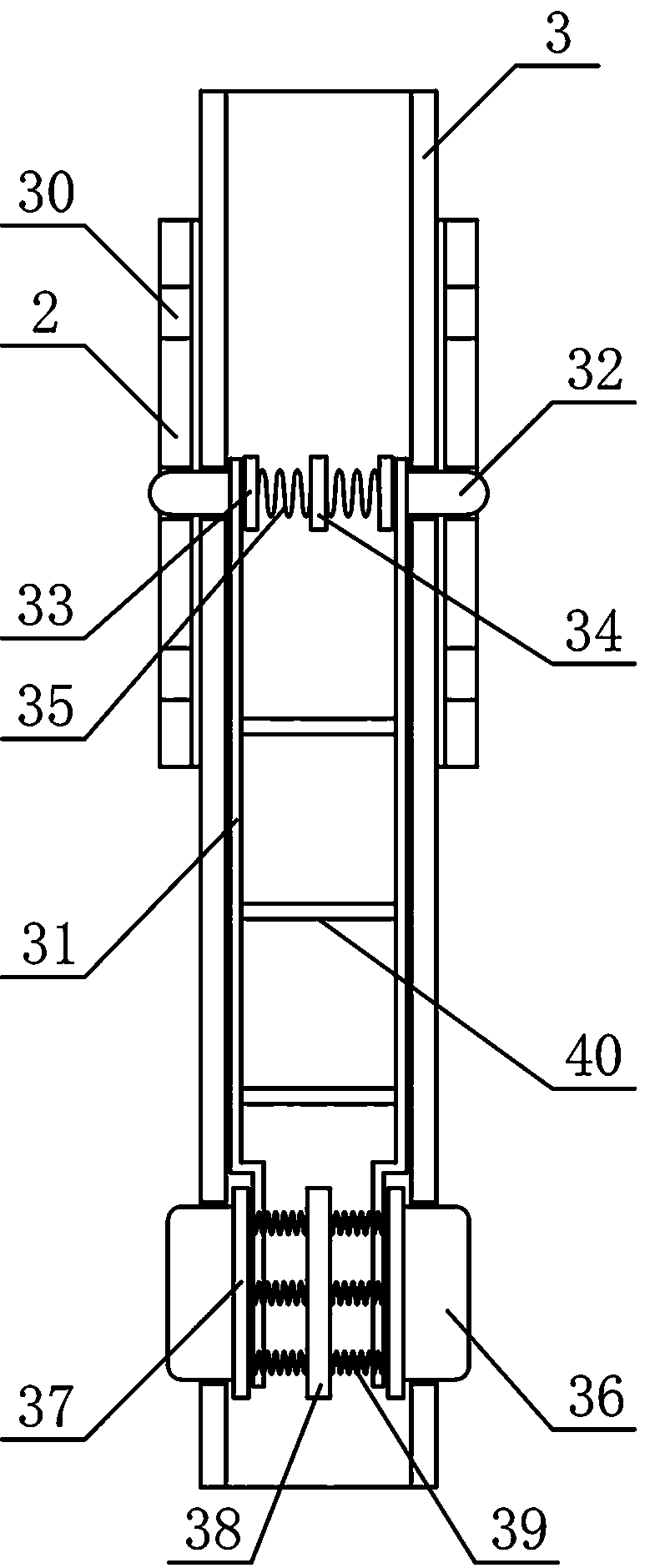

[0015] Such as figure 1 with figure 2 As shown, an aluminum alloy storage rack of the present invention includes a connecting bottom plate 1, an adjusting sleeve 2, an adjusting connecting rod 3, a main storage board 4, an auxiliary storage board 5, an upper storage board 6 and a lower storage board 7, and the connecting bottom board 1 Vertically fixed on the building wall 8, a plurality of fixing bolts 9 are evenly arranged between the outer side of the connecting bottom plate 1 and the building wall 8, and the two ends of one side of the connecting bottom plate 1 are respectively vertically fixed with an adjusting sleeve 2 and an adjusting connecting rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com