Spring-type safety socket with anti-electric shock function

A safety socket and anti-shock technology, which is applied in the direction of preventing contact with live contacts, devices, circuits, contact parts, etc., can solve problems such as unstable power connection, life-threatening safety hazards, and hidden dangers of electric shock, so as to increase structural stability, Ensuring airtightness and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

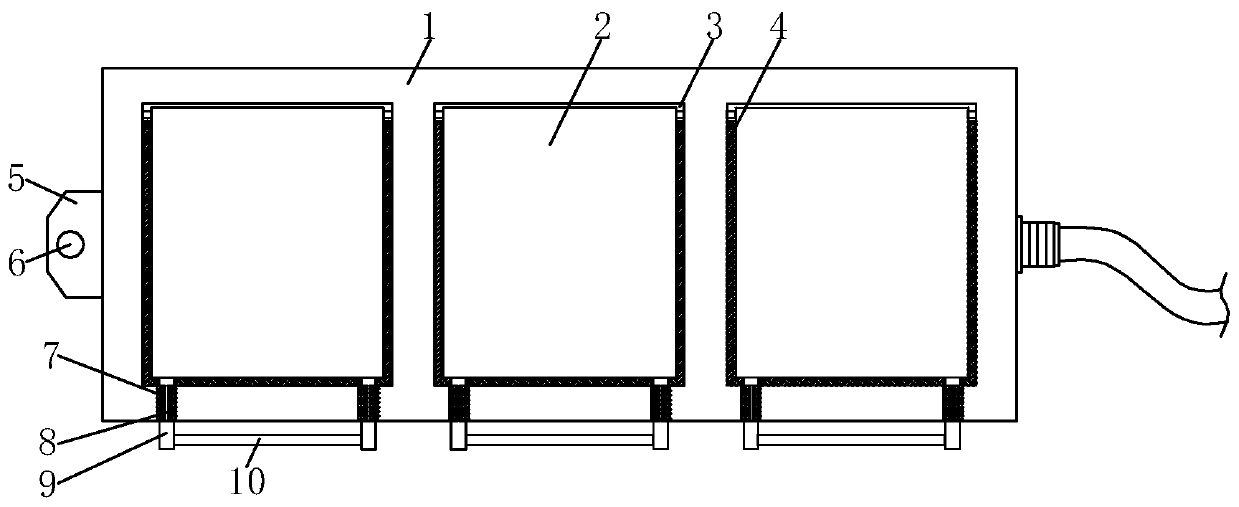

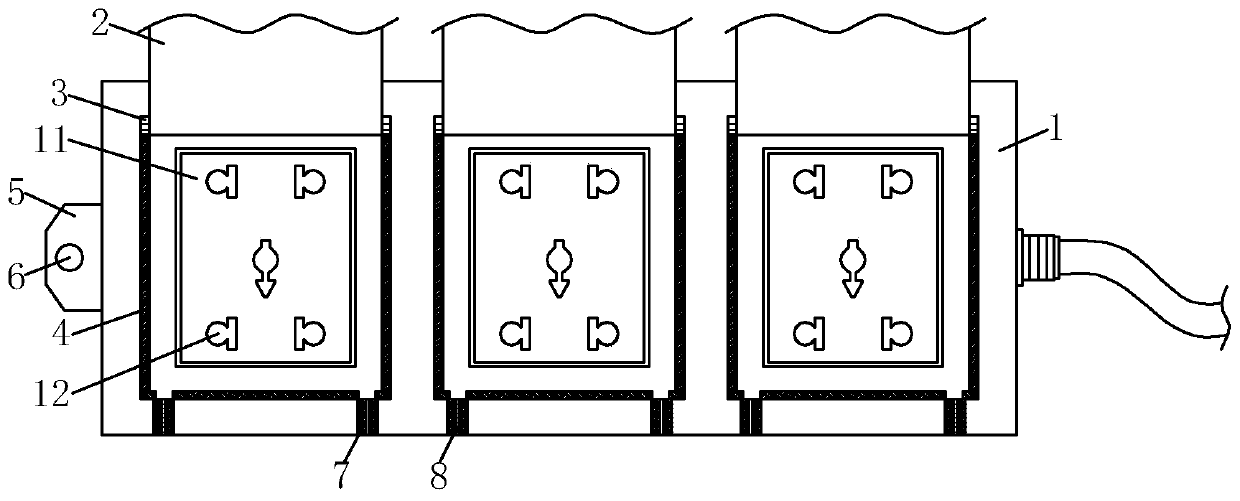

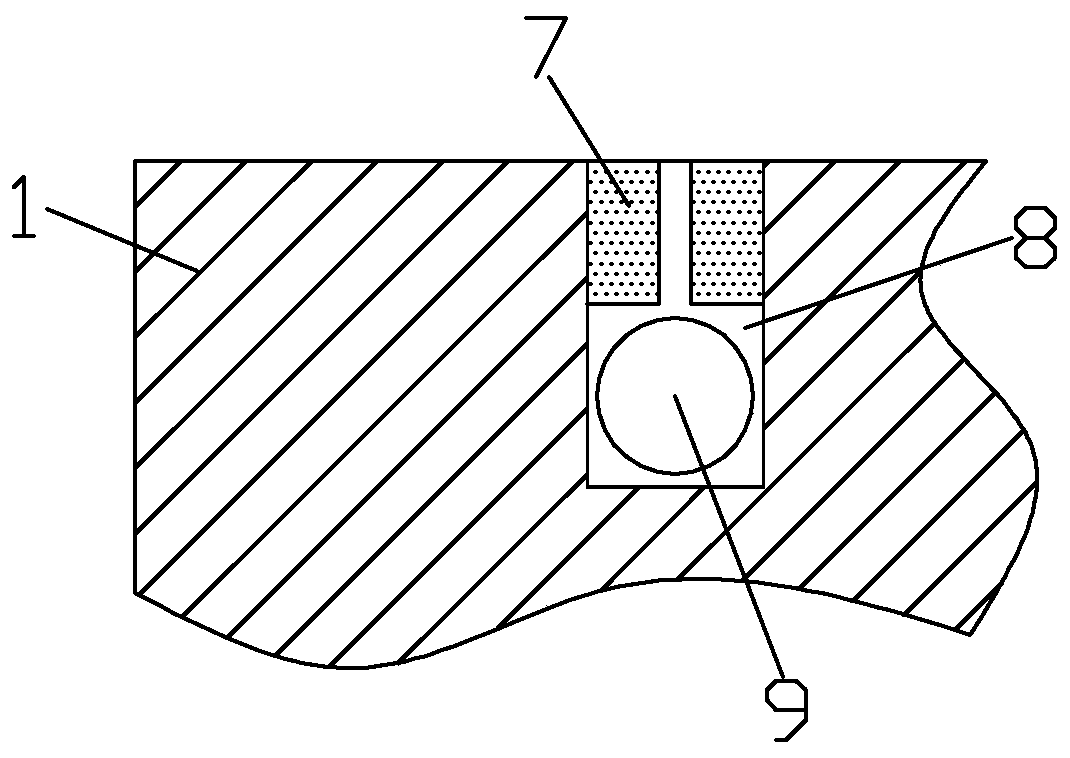

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0026] refer to Figure 1-6 , a spring-type safety socket with anti-shock function, including a shell 1, the shell 1 is made of ABS plastic material, by using the shell 1 made of ABS plastic material, so that the socket has high strength and hardness, and at the same time has a relatively high Strong heat resistance and corrosion resistance, also has strong impact resistance and toughness, can effectively play the role of anti-fall.

[0027] A fixing mechanism is fixedly installed in the middle part of one side of the housing 1, and the fixing mechanism includes a fixing piece 5 fixedly installed in the middle part of one side of the casing 1, and a through hole 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com