Optimal design method of centrifugal pump impeller

A centrifugal pump impeller, optimized design technology, applied in the components, pump, calculation and other directions of the pumping device for elastic fluid, to achieve the effect of optimization accuracy, good operating efficiency and operating stability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

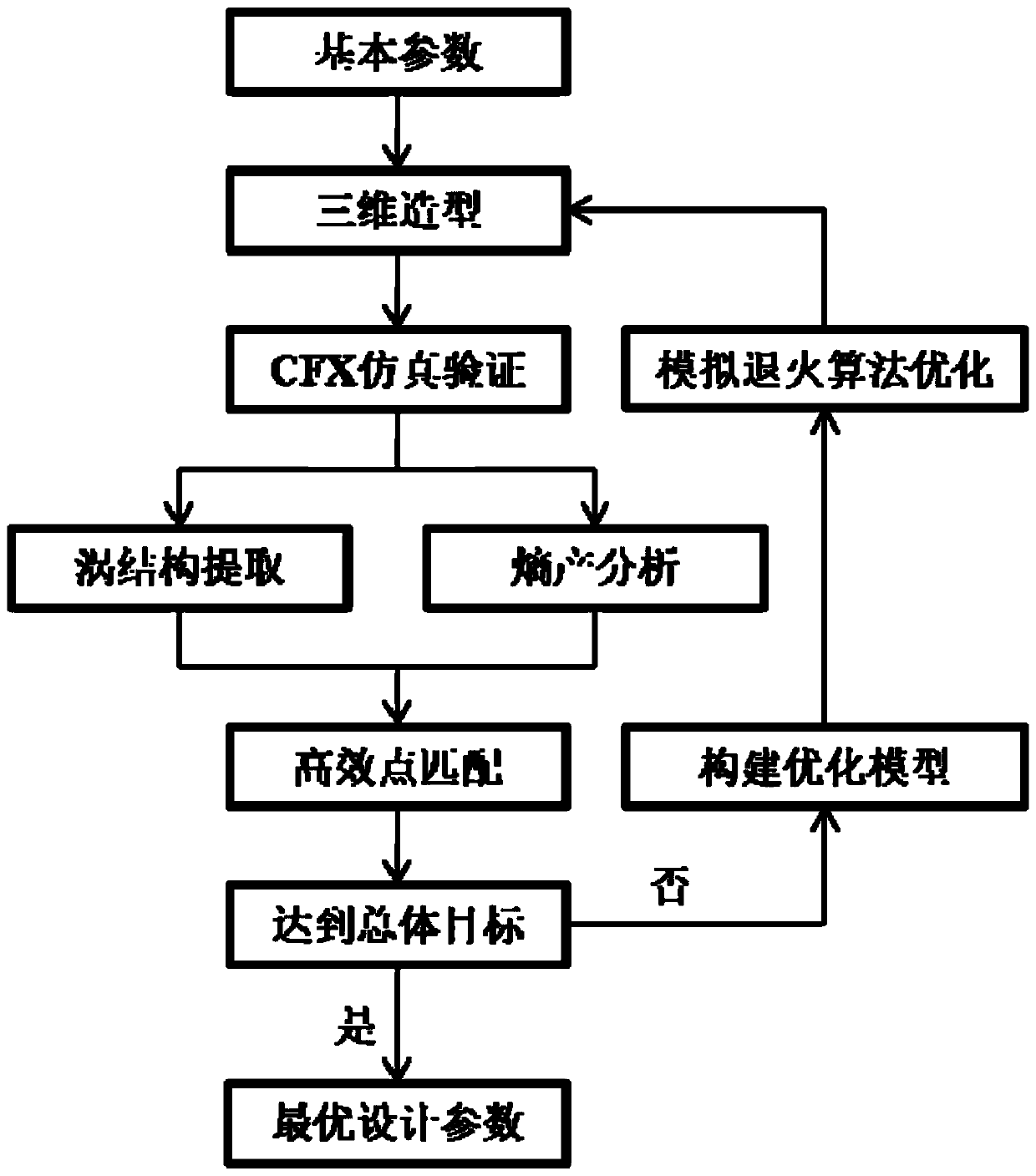

[0057] Such as figure 1 The optimal design method of the centrifugal pump impeller shown in the following steps:

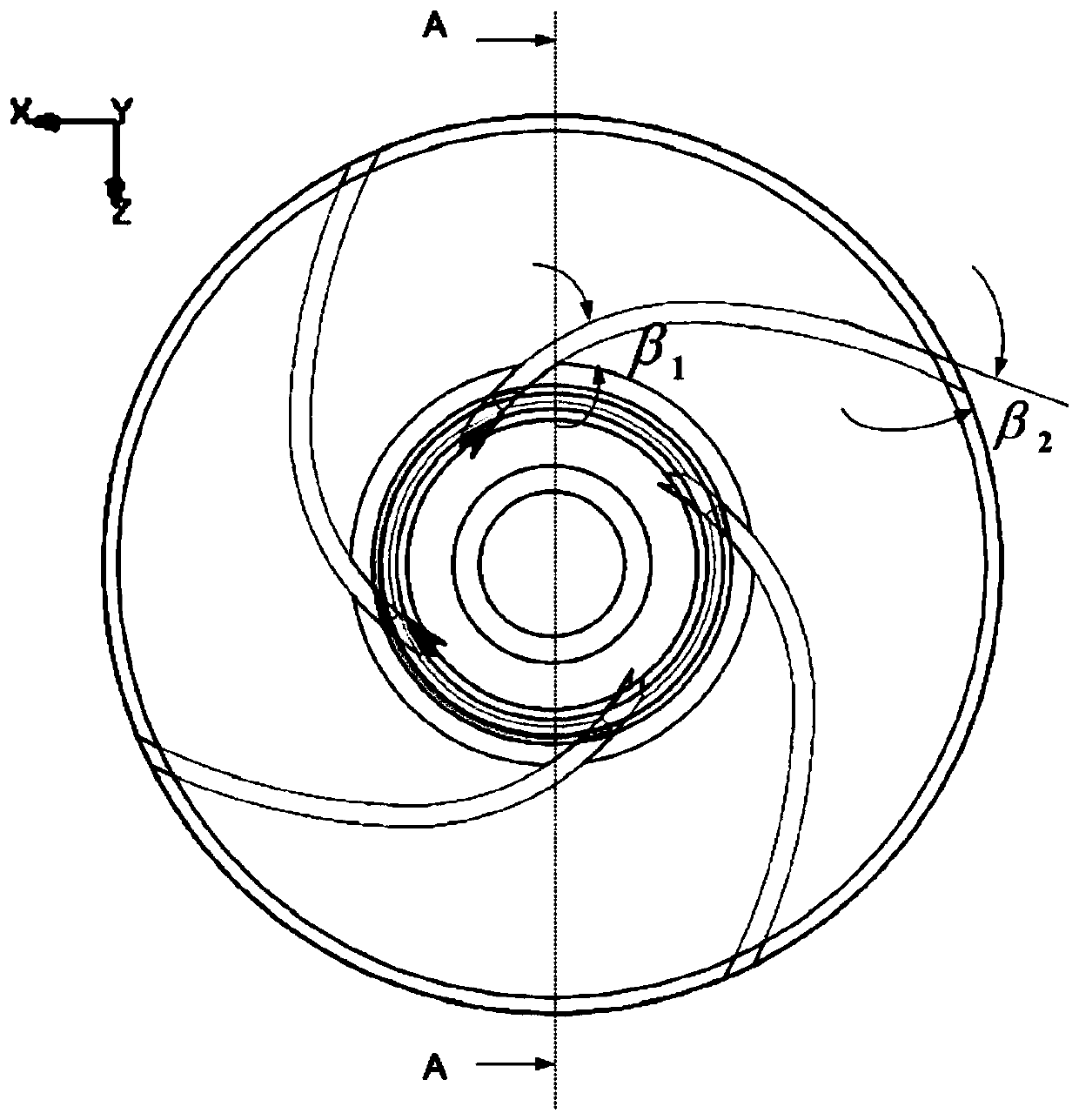

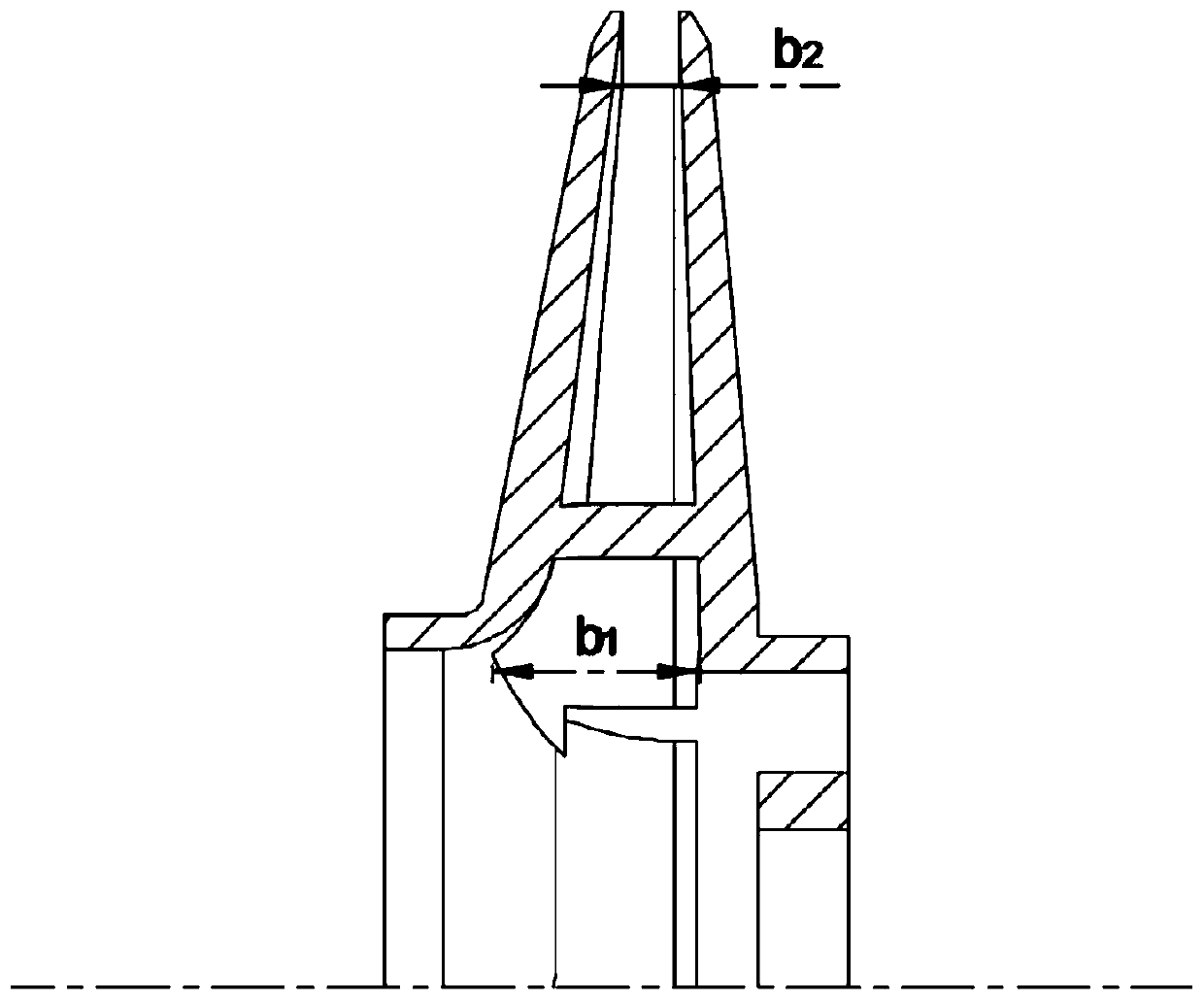

[0058] 1) First, according to the design requirements and design experience, a set of parameters to be optimized is specifically determined: impeller inlet width b 1 , impeller outlet width b 2 , blade inlet angle β 1 , blade outlet angle β 2 , blade number z( figure 2 with image 3 The angle and the width of the entrance and exit are marked), this set of parameters to be optimized and the constraint range are given below. Other impeller parameters are used as design constants;

[0059] Among them, the design parameters that need to be optimized for the centrifugal pump impeller have the following constraints:

[0060]

[0061] 30°1 <40°

[0062] 15°2 <40°

[0063]

[0064] In the above formula:

[0065] K m1 -Impeller inlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com