Crawling device for sealant filling for gaps among ceramic tiles of wall body, and operation method

A technology of crawling device and beautifying agent, which is applied in the field of crawling device filled with beautifying agent, can solve the problem of wasting beautifying agent and achieve the effect of convenient use and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

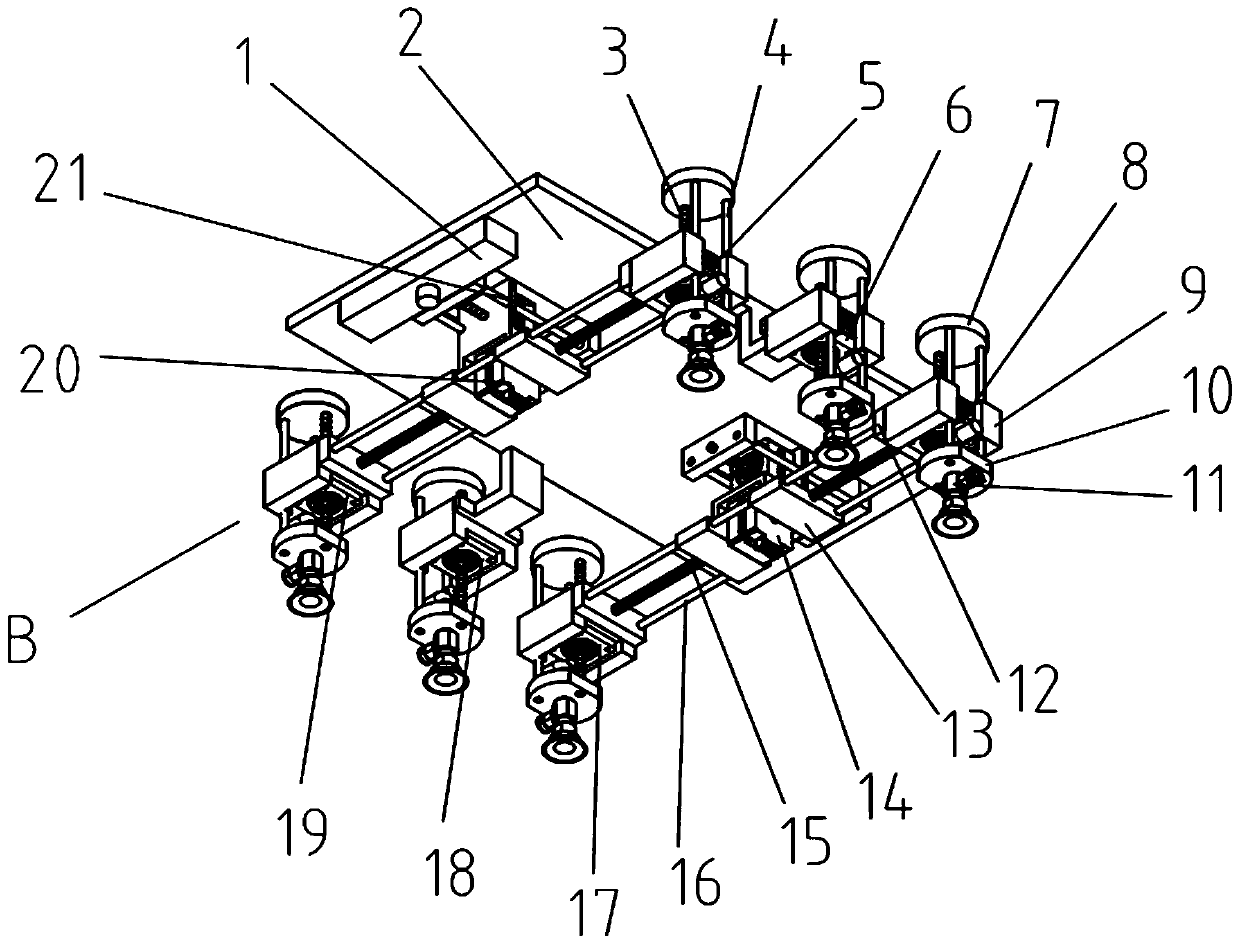

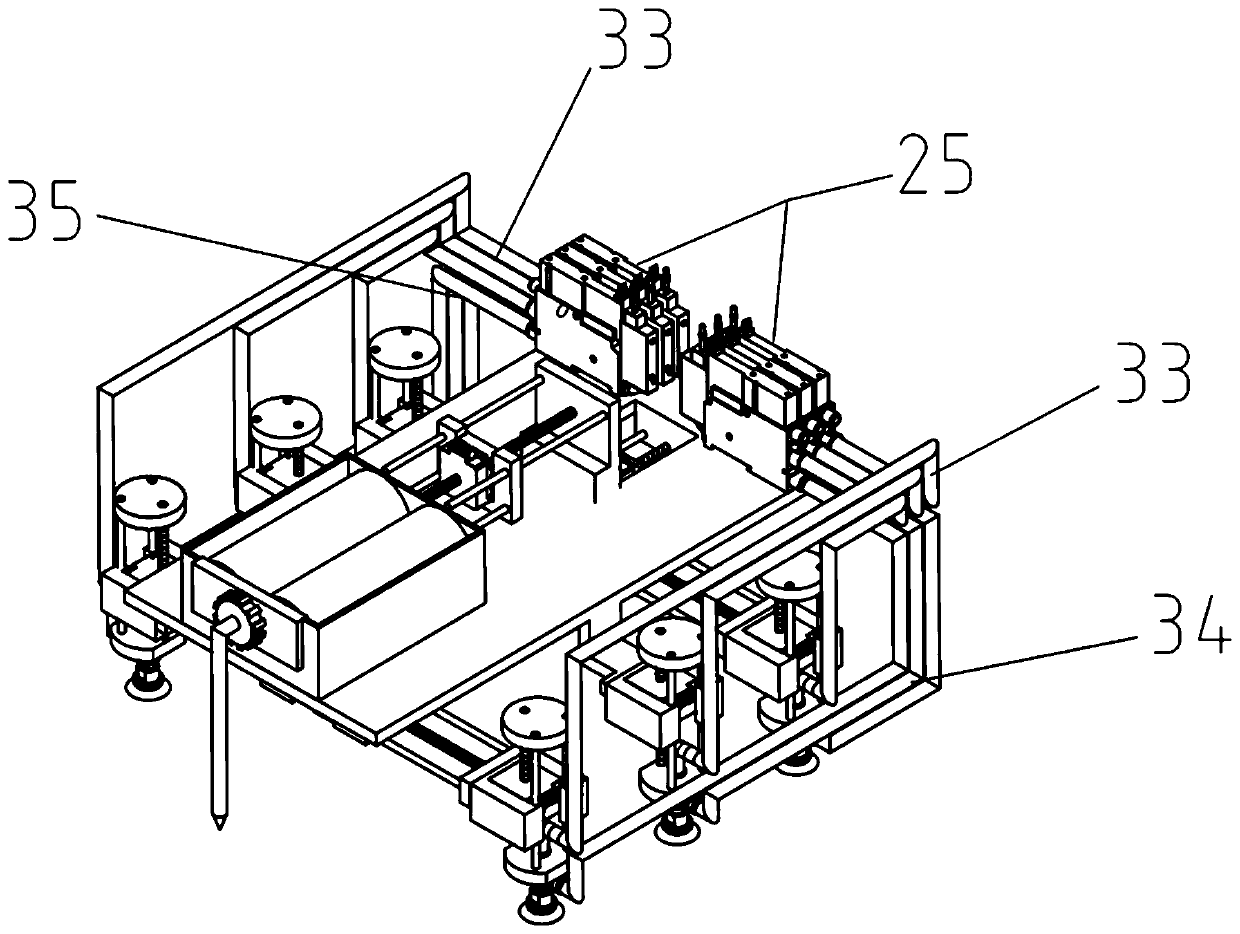

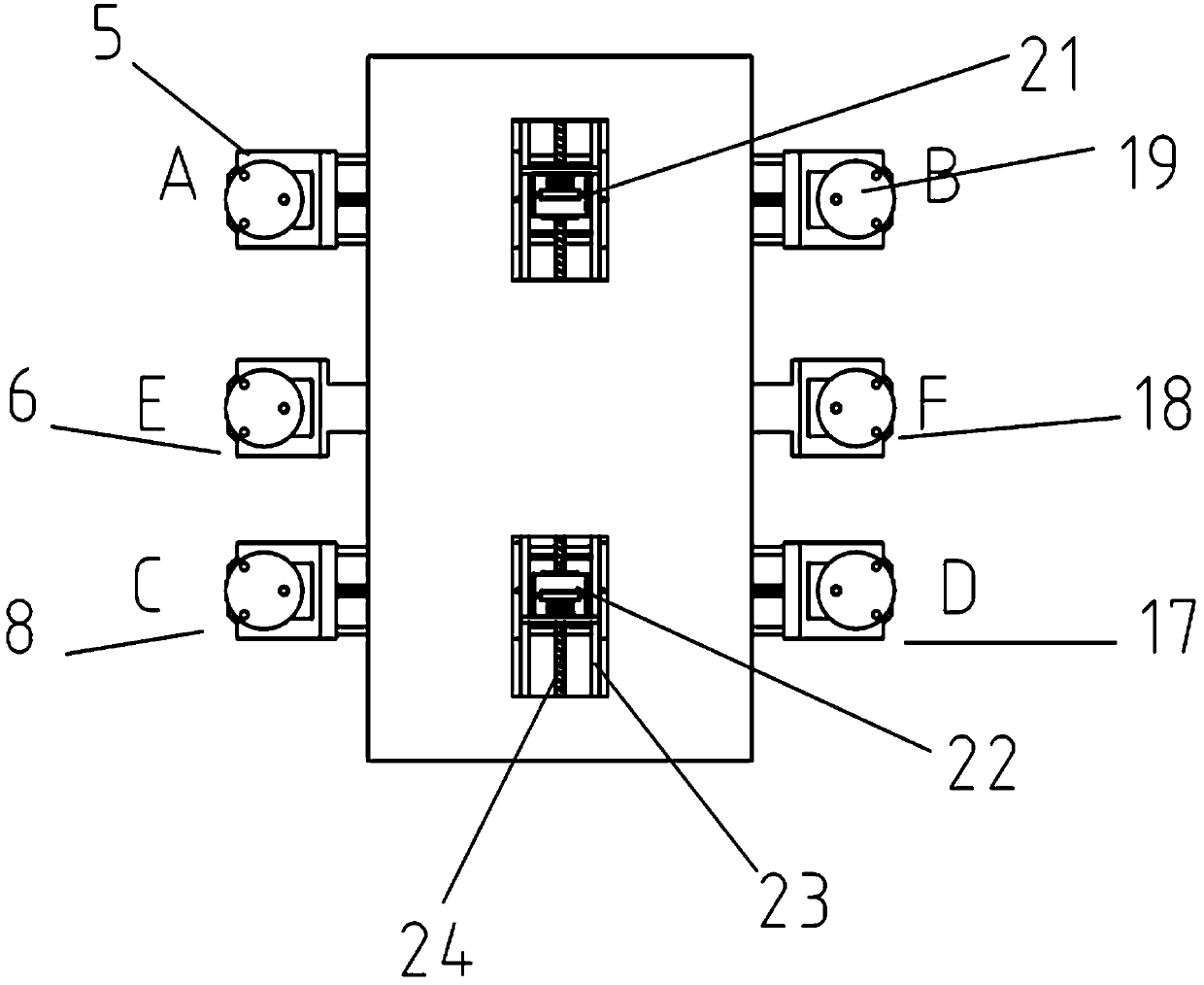

[0029] see Figure 1-4 , a crawling device filled with beautifying agent for gaps between wall tiles, which includes a car board 2, and a spray mechanism for storing and evenly extruding the beautifying agent is installed on the top of the car board 2, and the car board The front and rear ends of the bottom of 2 are equipped with a crawling mechanism for driving the entire device to move forward, backward, left and right; the end of the crawling mechanism is equipped with a vacuum mechanism for adsorption and connection with the tile surface; the vehicle plate The two sides in the middle of 2 are symmetrically equipped with a walking coordination mechanism, and the walking coordination mechanism is also equipped with a vacuum mechanism. The crawling device with the above structure can be used for automatic filling of the beautifying agent in the wall tile gap, and then replace the traditional manual operation method, which greatly improves the work efficiency. Through the abov...

Embodiment 2

[0037] The operation method of the crawling device filled with the beautifying agent in the gap between the wall tiles described in any one, it comprises the following steps:

[0038] Step1: Start the vacuum generator 25, and the six suction cups drive the device to be adsorbed on the wall. At this time, the D-type stepping motor 22 and the C-type stepping motor 21 are at the bottom, and the A-type stepping motor 14 and the B-type stepping motor 20 start to move the part connected by the motor connector 13 from the initial position, and at the same time the distance sensor 1 measures the distance H to the wall and starts timing T; when the change value of the distance H measured by the distance sensor 1 is greater than the set h, Record the time T1 at this time. When the change value of the distance H measured by the distance sensor 1 is greater than the set h again, record the time T2 at this time, and then the A-type stepping motor 14 and B-type stepping motor 20 rotate in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com