Microwave sterilization apparatus

A microwave sterilization device and cabinet technology, applied in food science, food preservation, application and other directions, can solve the problems of poor sterilization effect and incomplete sterilization, and achieve the effect of improving sterilization effect, reducing water chestnut effect and microwave uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

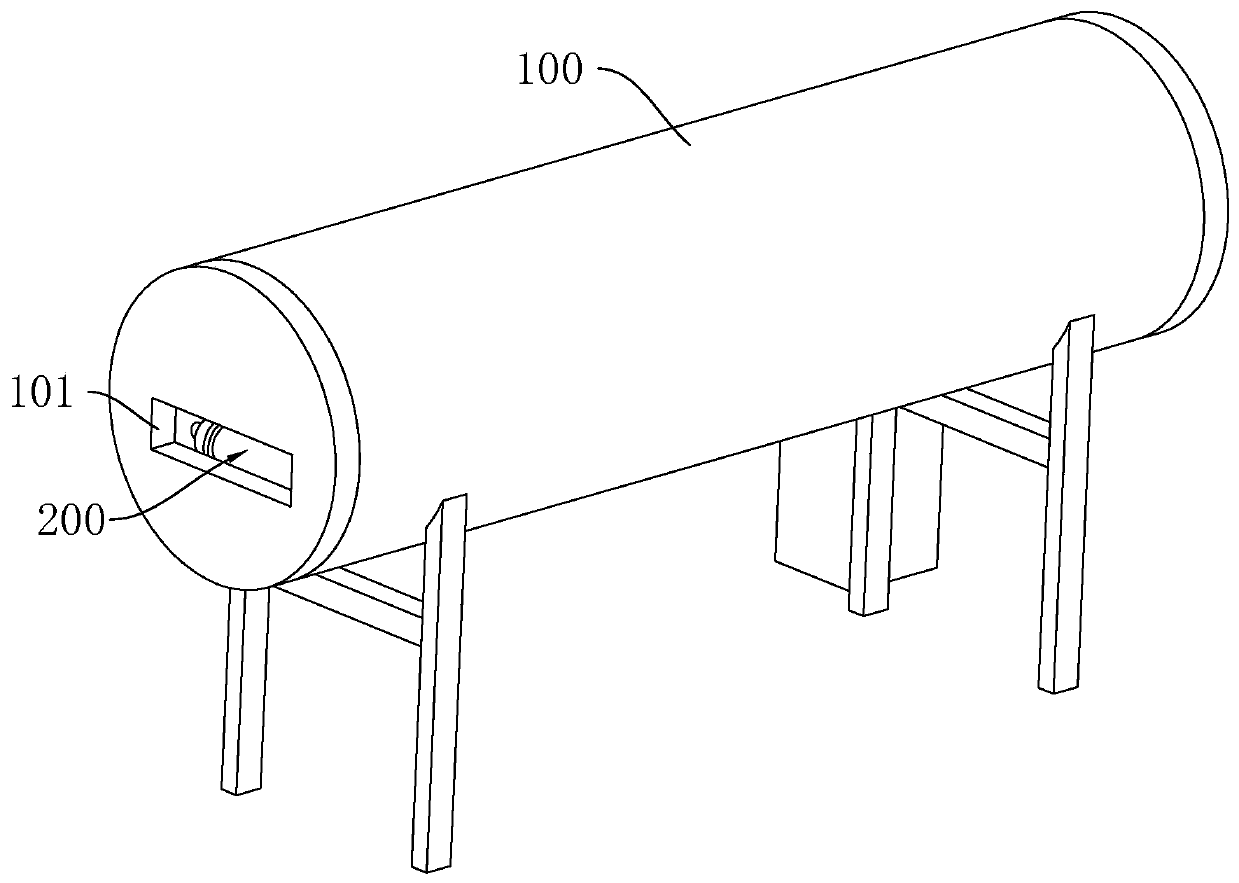

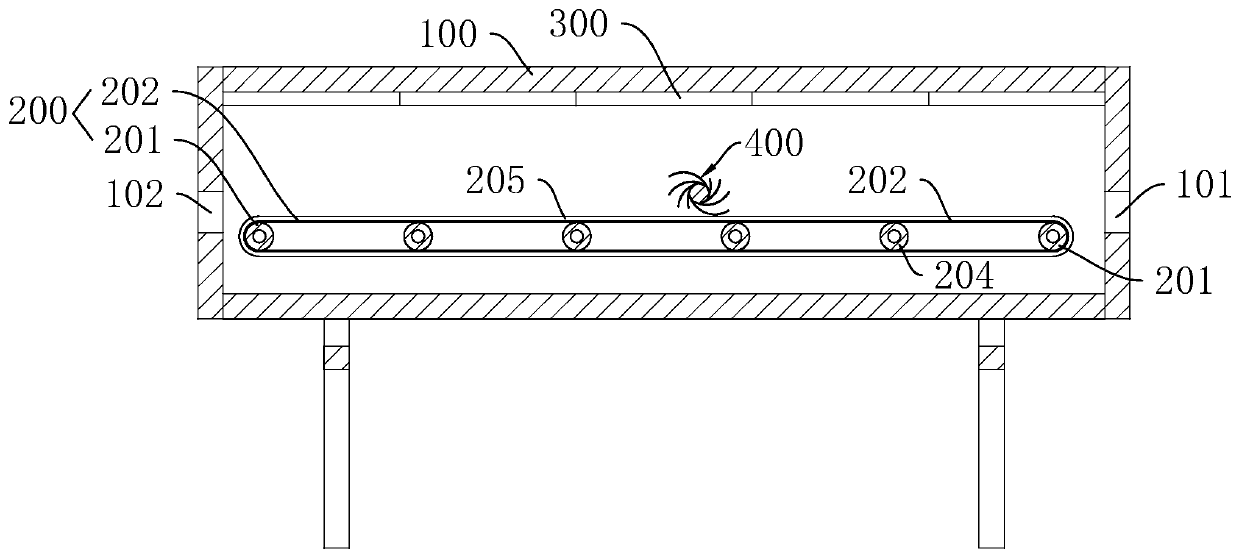

[0036] Embodiment: a kind of microwave sterilization device, as figure 1 As shown, a box body 100 and a delivery structure 200 are included. The box body 100 is a cylindrical shape placed horizontally, and a cylindrical cavity is coaxially opened inside it. The two axial ends of the box body 100 are respectively provided with an inlet 101 and an outlet 102 (see figure 2 ). The conveying structure 200 conveys the material from the inlet 101 into the box body 100 , and then conveys the material out of the box body 100 through the outlet 102 .

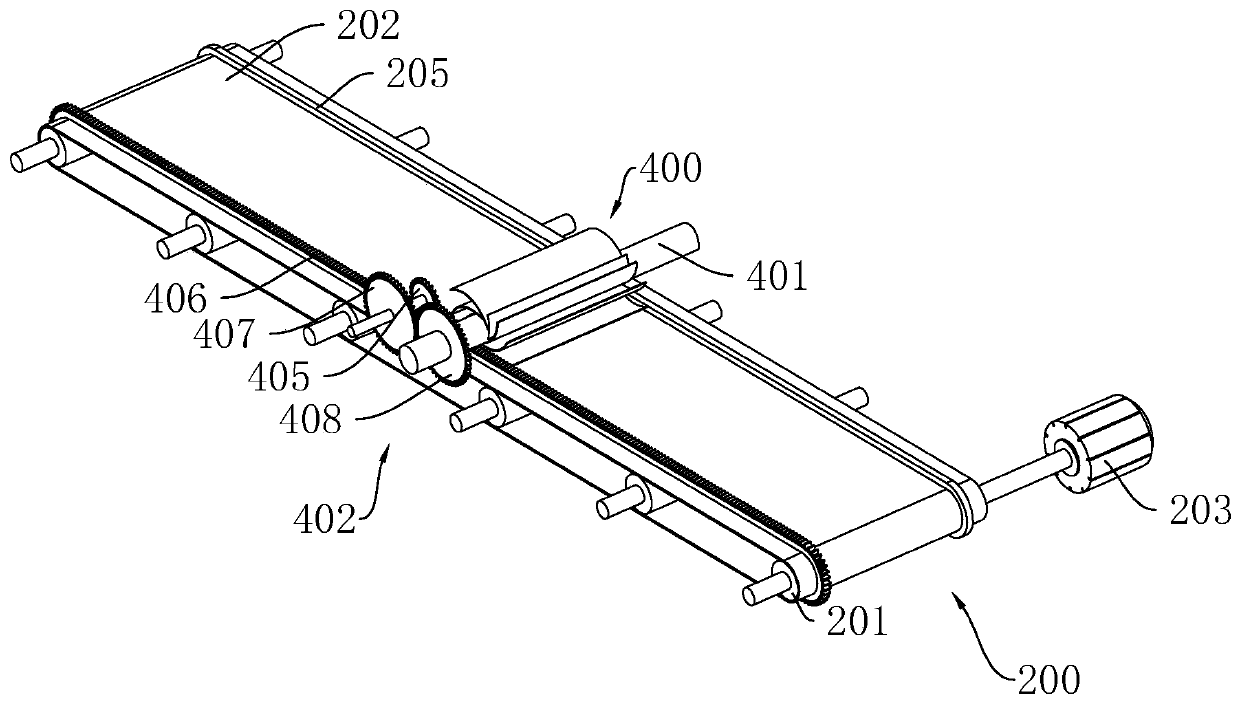

[0037] Such as figure 2 As shown, the conveying structure 200 includes a conveying roller 201 and a conveying belt 202 . There are two transmission rollers 201, which are respectively connected to the two ends of the box body 100 in rotation. The conveyor belt 202 is sleeved on the two transmission rollers 201. The two sides of the conveyor belt 202 perpendicular to the conveying direction are fixedly connected with protrusions 205....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com