Paper mill sewage filtering device

A technology for paper mills and sewage, applied in the fields of filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of impact, increase labor costs, and reduce sewage passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

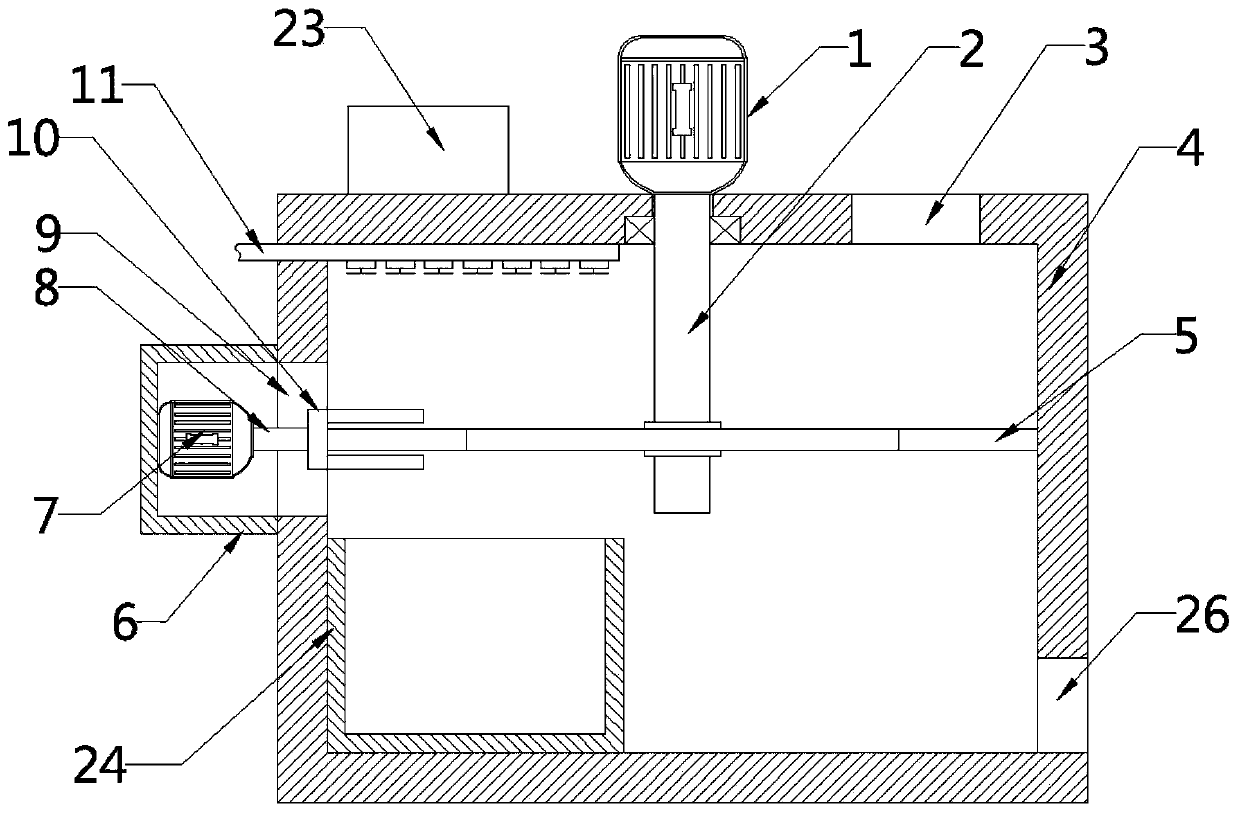

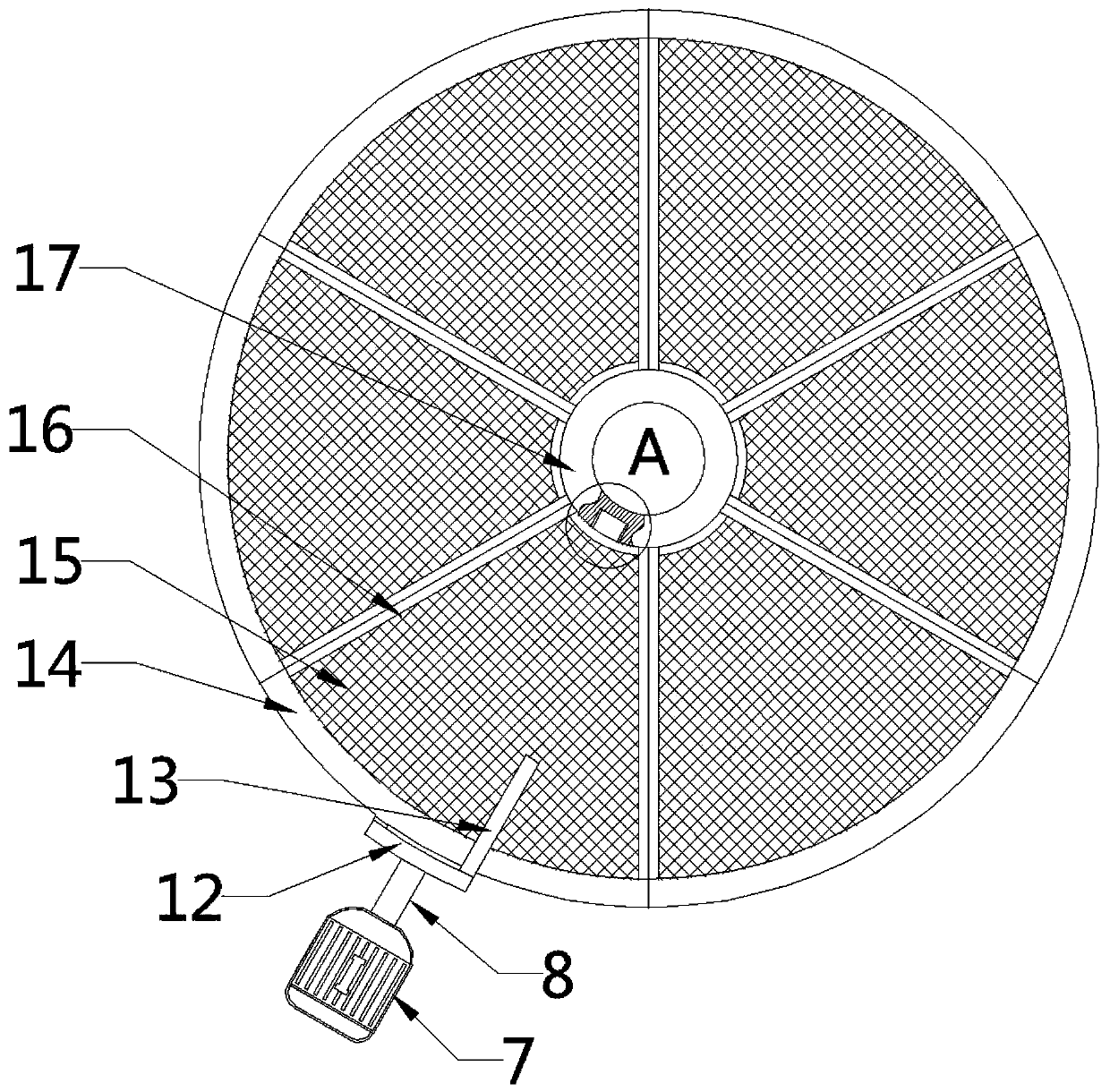

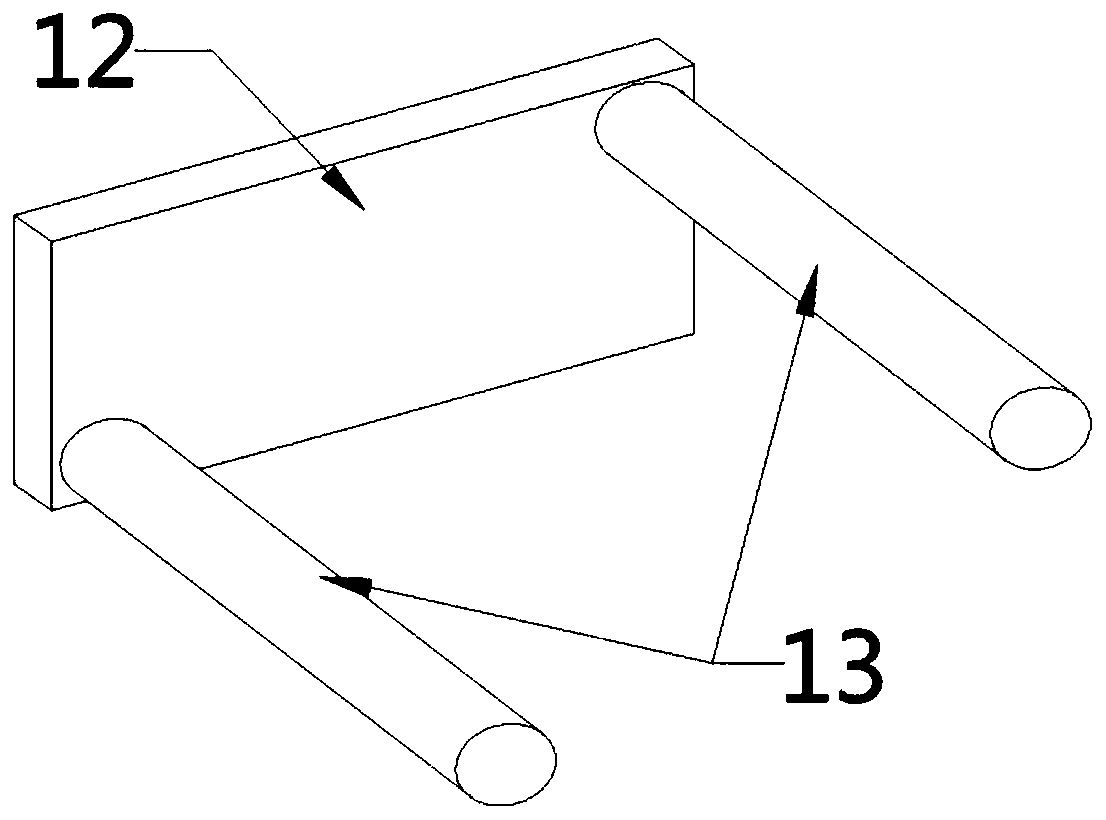

[0028] see Figure 1-5 , the present embodiment provides a paper mill sewage filtering device, comprising a filter box 4, the upper side of the filter box 4 is provided with a water inlet 3, and the bottom of the filter box 4 is provided with a drain 26, and the filter box is 4. A filter assembly 5 is rotatably installed inside. The filter assembly 5 includes a central ring 17 and several filter screen assemblies rotatably arranged outside the central ring 17. The inside of the filter box 4 is provided with a A flap assembly that drives the filter screen assembly to rotate, a cleaning assembly for removing debris from the rotated filter screen assembly is provided above the flap assembly, and a collection box 24 for collecting debris is provided below the flap assembly .

[0029] The papermaking sewage is injected into the filter box 4 from the water inlet 3, and the fiber debris and other sundries in the papermaking sewage are filtered through the filter assembly, and the fi...

Embodiment 2

[0047] see figure 1 , a sewage filter device for paper mills. Compared with Embodiment 1 in this embodiment, the upper part of the filter box 4 is also provided with a controller 23 electrically connected to the first motor 1 and the second motor 7 respectively. The controller 23 detects the rotation angle of the first motor 1. When the first motor 1 rotates the centerline of the filter screen body 15 corresponding to a certain filter screen assembly to the extension line of the second rotating shaft 8, the controller 23 Control the second motor 7 to start, so that the second motor 23 rotates 180 degrees, and then drives the filter screen assembly to turn over 180 degrees, and the fiber debris on the upper part of the filter screen assembly is turned to the lower part.

[0048] The detection of the first motor 1 by the controller 23 and the control means to the second motor 7 belong to the prior art, and will not be repeated here. The model of the controller 23 is not limited,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com