A method for ultrasonic measurement of surface stress tensor of rolled metal materials

A technology of surface stress and metal materials, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, force measurement, and use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. Quantitative measurement, difficult to determine the principal stress direction and other problems, to achieve the effect of accurate establishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] A method for ultrasonically measuring the surface stress tensor of a rolled metal material. The workpiece to be tested described in this example is a rolled aluminum alloy polygonal tensile sample under different loading forces. The measurement steps are as follows:

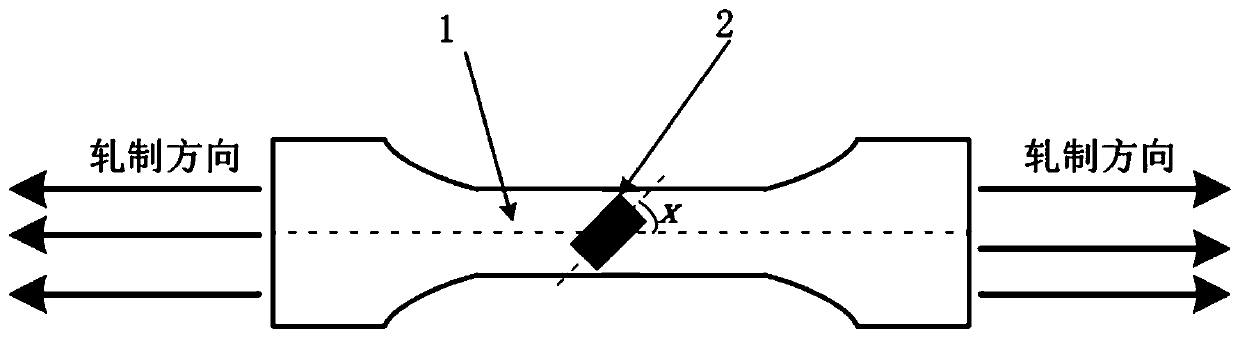

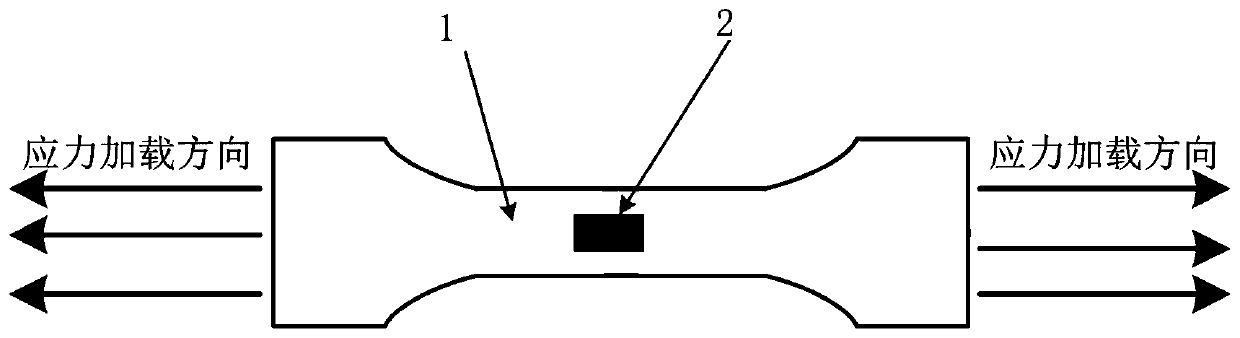

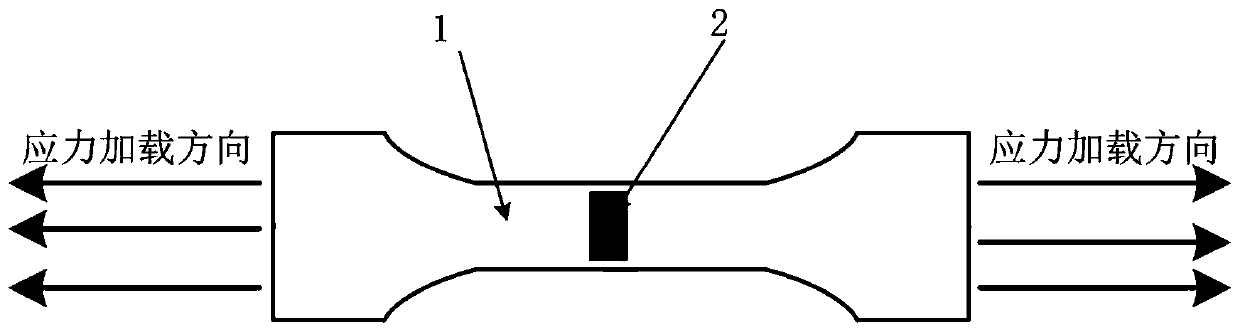

[0050] S1. Make a zero-stress tensile sample of the same material as the workpiece to be tested along the rolling direction (making a tensile sample along the rolling direction refers to the tensile direction of the tensile sample, that is, the stress during the tensile test The loading direction is the same as the material rolling direction,), such as figure 1 As shown in , ultrasonic probes are placed on the surface of the tensile sample along different orientation angles x, and the ultrasonic stress test is carried out, and the zero stress acoustic time t corresponding to different orientation angles x is obtained 0 , through multiple sets of orientation angles x and their corresponding zero stress aco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com