Motor-driven flameproof motor explosion pressure measuring test device and method

A technology of dragging motor and explosion pressure, applied in the direction of measuring device, measuring blasting force, instrument, etc., can solve the problem of inability to measure the explosion pressure of the motor under test, unable to drive the motor under test, etc., so as to reduce the requirements and reduce the risk factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the examples.

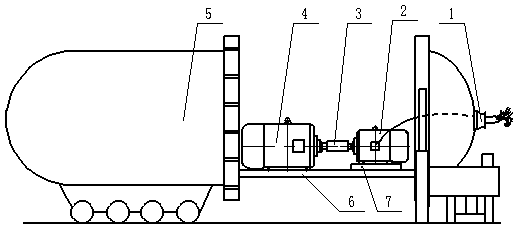

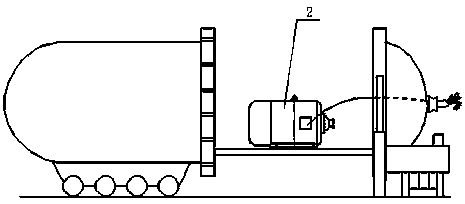

[0023] The invention discloses a motor-driven explosion-proof motor explosion pressure measurement test device, which includes an explosion-proof test tank 5, a test device arranged inside the explosion-proof test tank 5, and a power cable lead-in device 1 connected with the test device, wherein:

[0024] The test device includes a support platform 6 arranged in the explosion-proof test tank 5, a drag motor height adjustment bracket 7 arranged on the support platform 6, a low voltage level drag motor 2 arranged on the drag motor height adjustment bracket 7, and a The connecting piece 3 connected to the low-voltage level driving motor 2, the high-voltage level tested motor 4 connected to the connecting piece 3 and arranged on the support platform 6;

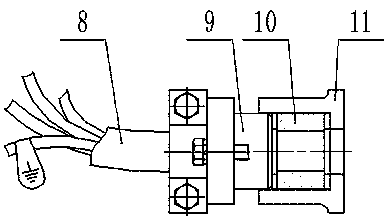

[0025] The power cable lead-in device 1 comprises an explosion-proof test tank base 11 that is sealed and arranged on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com