Spray-painting device for production of furniture

A technology for furniture and paint spraying tubes, which is applied in the direction of spraying devices, lighting devices, lighting devices, etc., can solve the problems of low painting efficiency, low work efficiency, and inconvenient use, and achieve increased painting efficiency, improved uniformity, and convenience. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

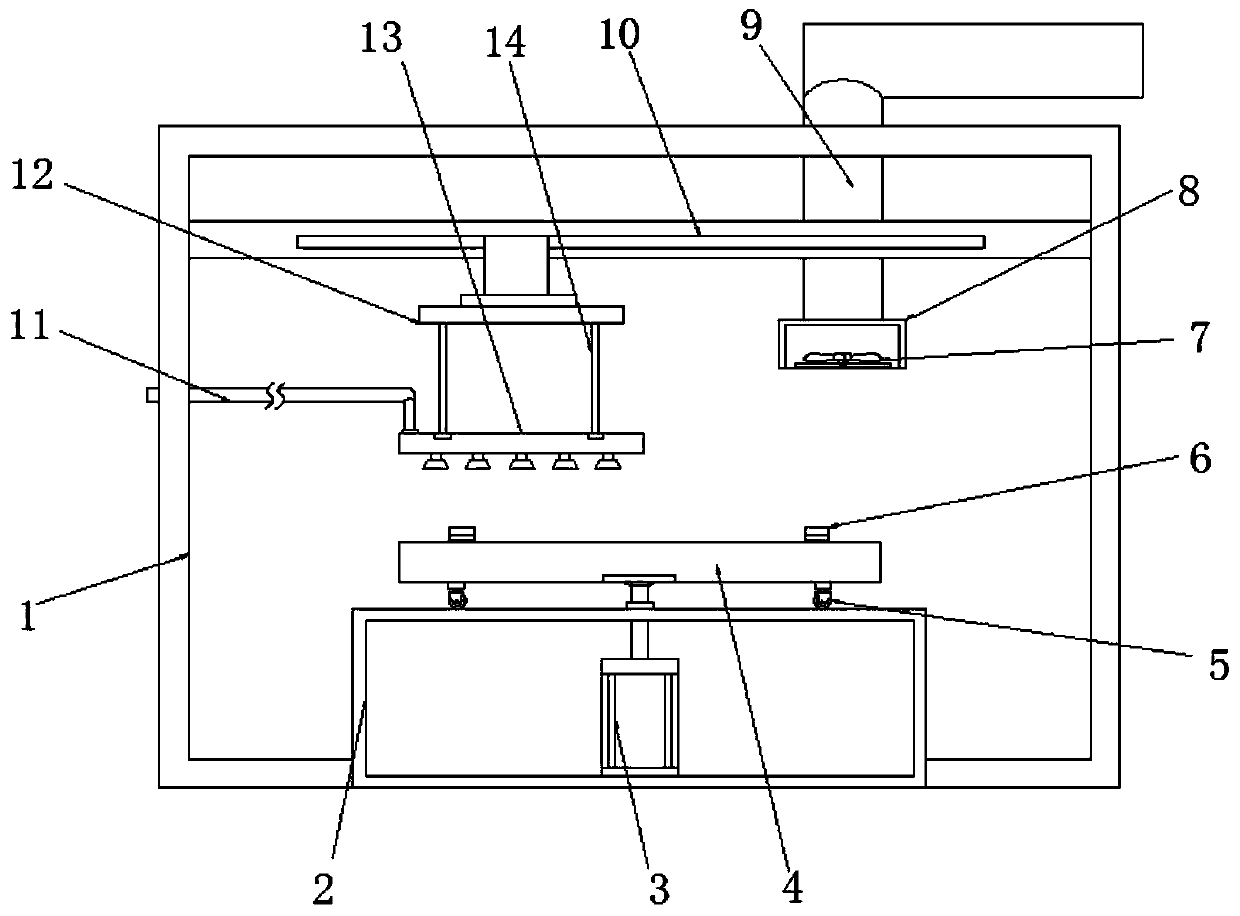

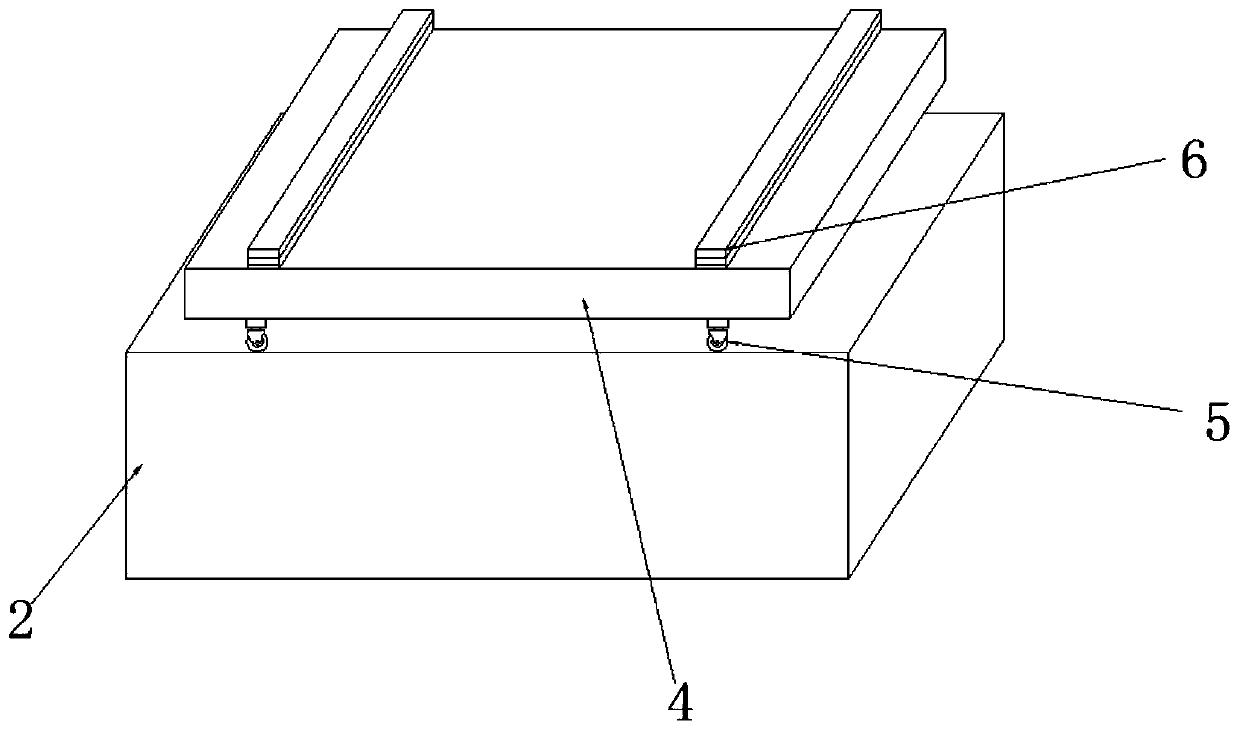

[0022] refer to figure 1 and figure 2 A painting device for furniture production, comprising a box body 1, a storage mechanism is fixed at the center of the bottom inner wall of the box body 1, the storage mechanism includes a storage table 2, a motor 3 is fixed inside the storage table 2, and the top of the output shaft of the motor 3 passes through The top outer wall of the storage table 2 is fixed with a storage board 4, and the four corners of the bottom outer wall of the storage board 4 are fixed with moving wheels 5 that are in contact with the storage table 2. The inner top of the cabinet 1 is fixed with an electric slide rail 10, and the electric slide rail 10 A connecting plate 12 is fixed at the bottom of the sliding group, and two connecting rods 14 are fixed at the bottom of the connecting plate 12, and the bottom end of the connecting rod 14 is fixed with a painting mechanism.

[0023] The paint-spraying mechanism includes a paint-spraying pipe 13, and the botto...

Embodiment 2

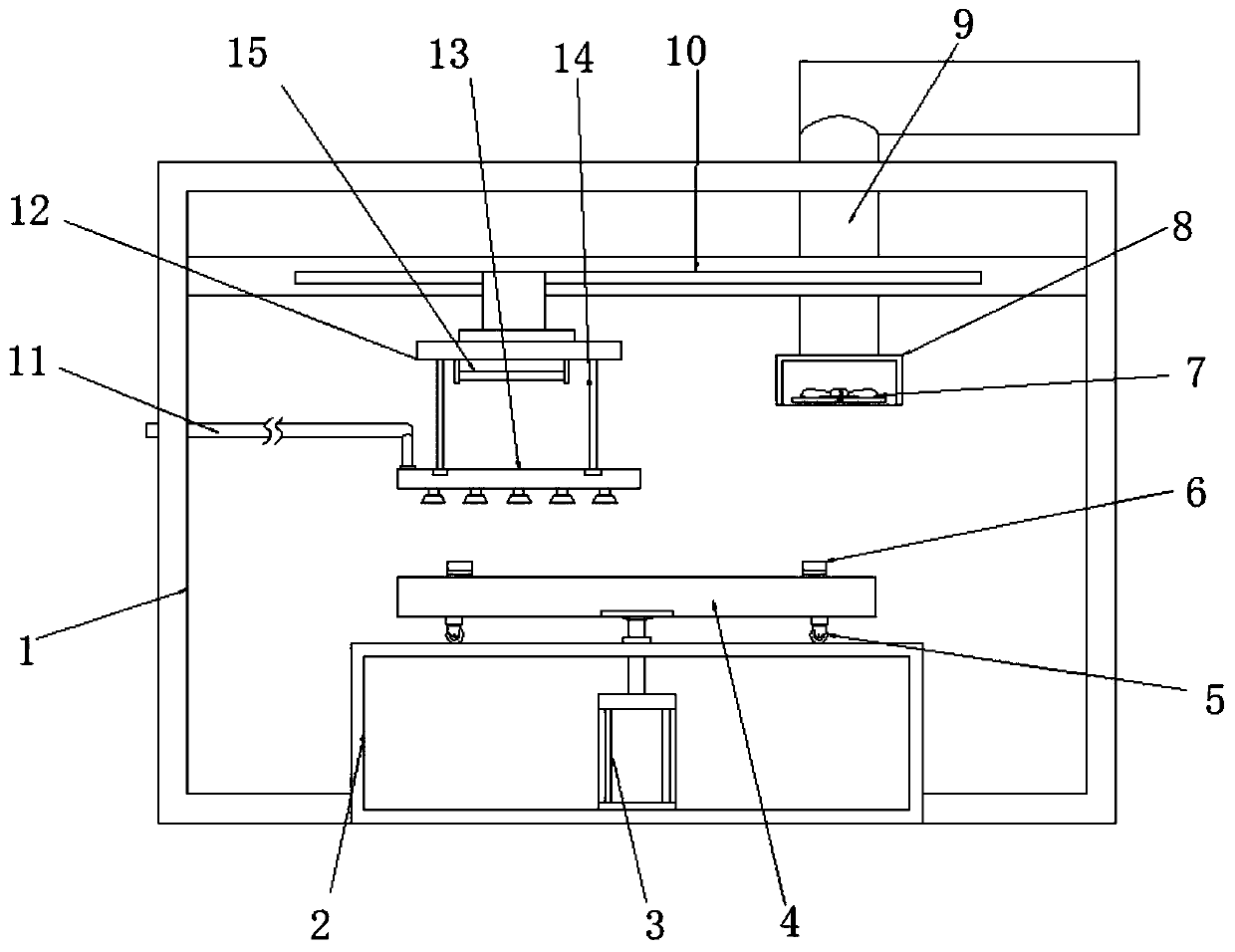

[0026] refer to image 3 , a painting device for furniture production. The difference between this embodiment and Embodiment 1 is that an illuminating lamp 15 is also fixed on the outer wall of the bottom of the connecting plate 12 .

[0027] The working principle of this embodiment: the illuminating lamp 15 can play an auxiliary role in increasing the intensity of light illumination inside the box body 1, so that the staff can supplement the light when the intensity of external light is weak, which is convenient for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com