Mechanical self-leveling express delivery transporting trolley

A self-leveling technology for carrying trolleys, which is applied in the direction of motor vehicles, trolleys, transportation and packaging, etc. It can solve the problems of tilting, damage, and reduced logistics efficiency of carrying trolleys, so as to improve the scope of application, improve applicability, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

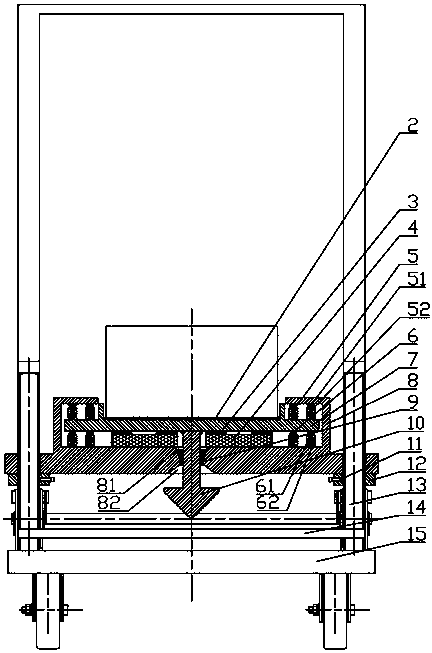

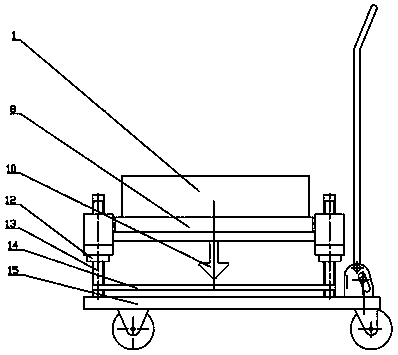

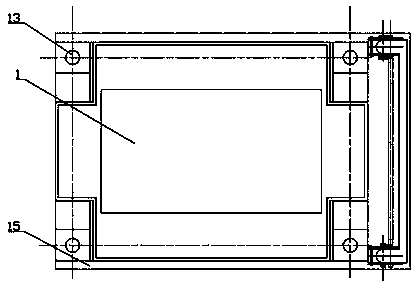

[0025] In this embodiment, the mechanical self-leveling express delivery trolley, such as figure 1 , figure 2 with image 3 As shown, it includes a support frame 13, a support plate 8, a load plate 7 and a weight 10, and the support frame 13 is connected and fixed with a carrier 15 through a support baffle plate 14; The cross-section is a support plate 8 with a convex structure, the four corners of the support plate 8 are provided with through holes that cooperate with the support frame 13, and an adjustment nut 12 is also fixedly connected to the lower end of the through hole of the support plate 8; the support frame 13 Through the through hole of the support plate 8 and threaded with the adjustment nut 12, the adjustment nut 12 can move up and down along the support frame 13 to push the support plate 8 to move up and down, and the adjustment nut 12 is fixed by the set screw 11, and double nuts can also be used fixed.

[0026] Both sides of the upper end of the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com