All-plastic emulsion pump

A technology of emulsion pump and plastic, applied in the field of emulsion pump, can solve the problem of inconvenient recycling and processing, and achieve the effect of facilitating recycling, realizing recycling, and avoiding compatibility risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

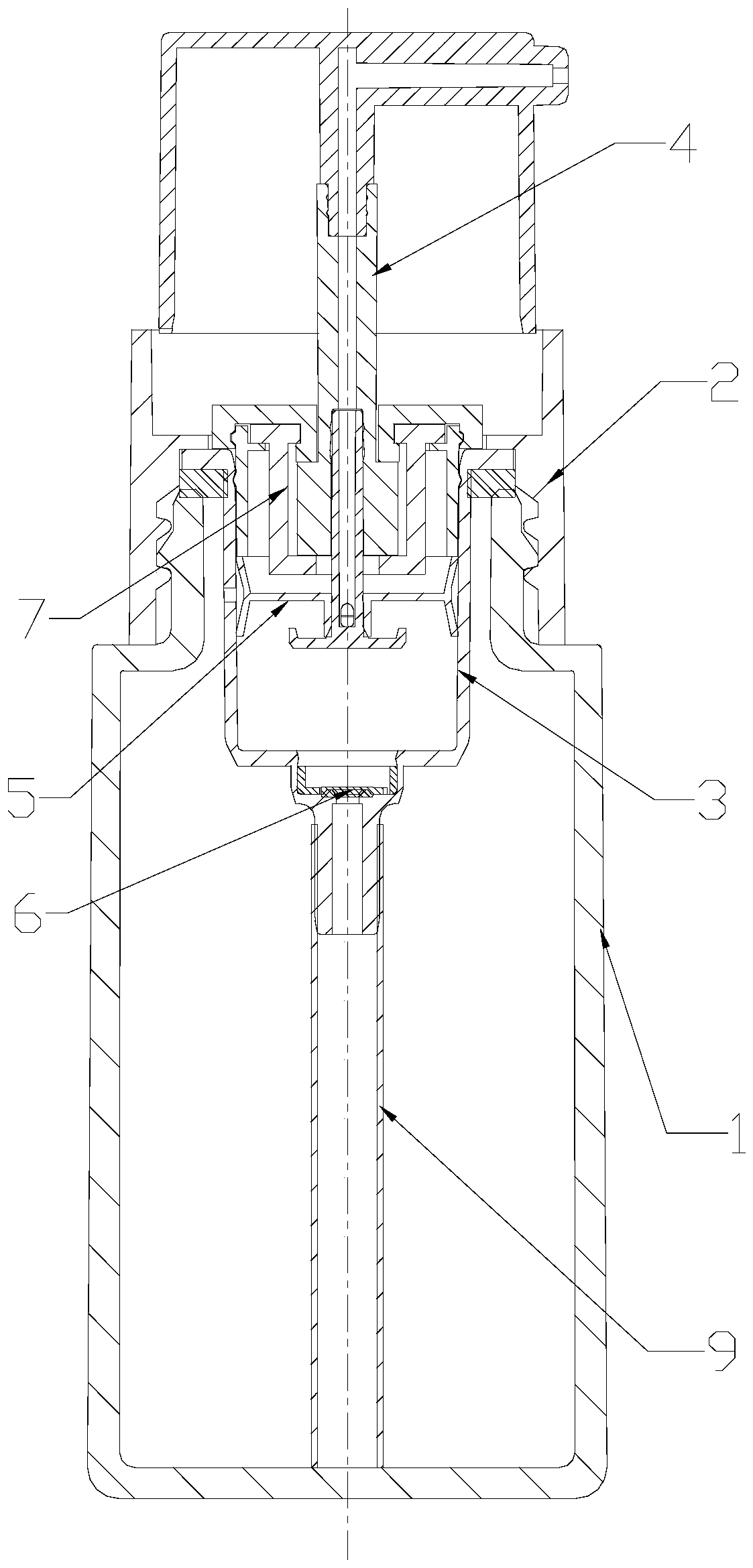

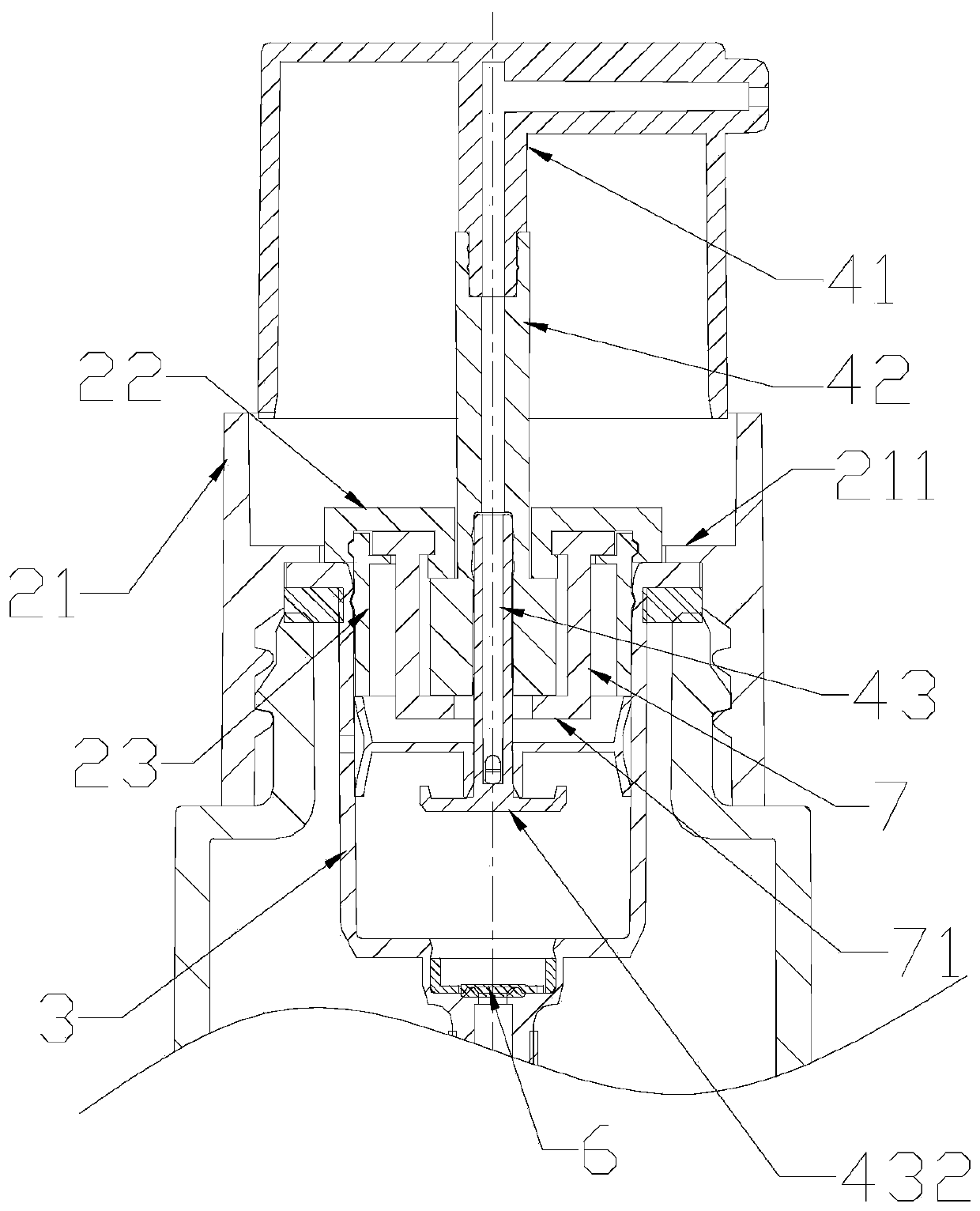

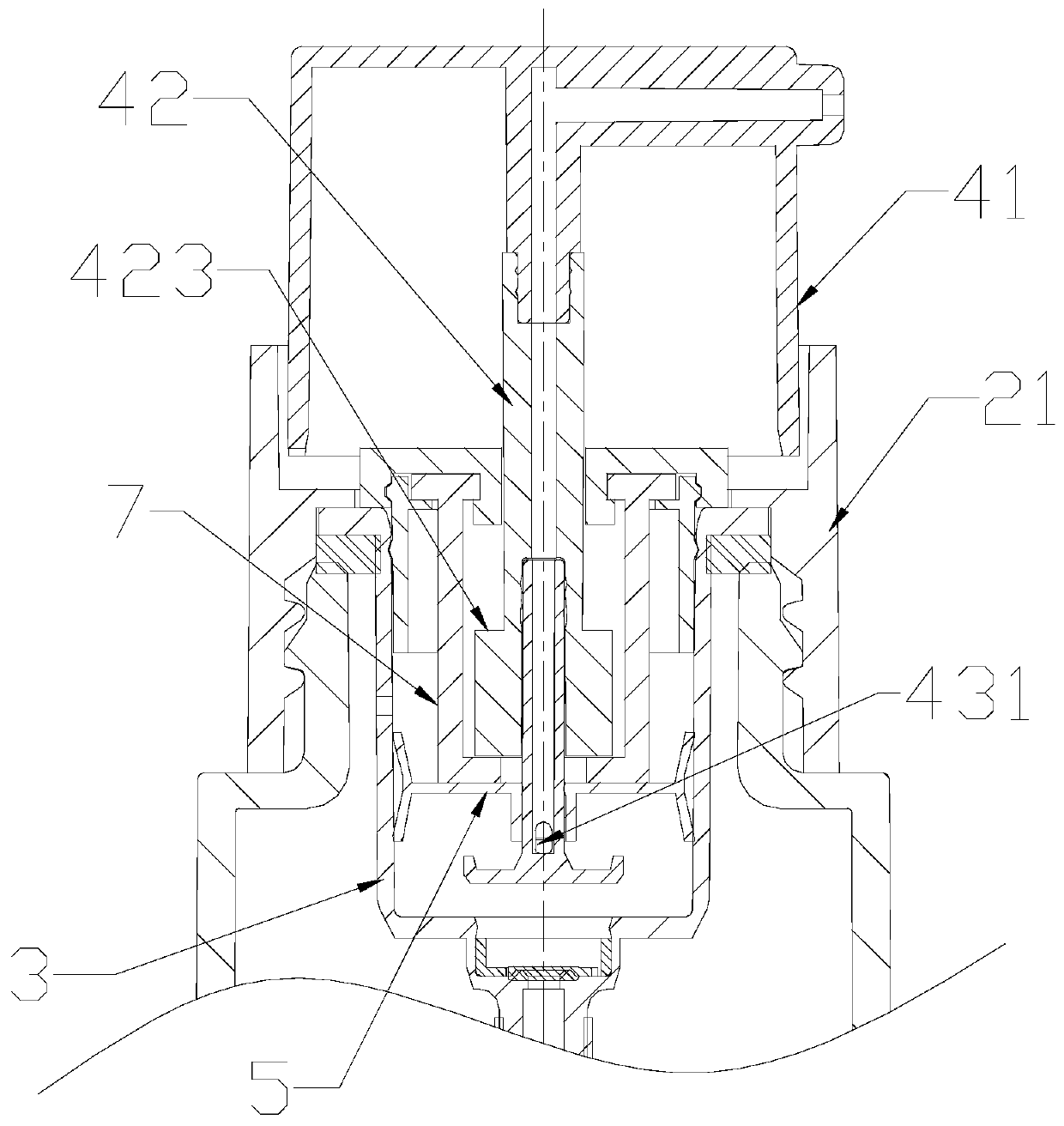

[0031] See attached Figure 1-4 As shown, an all-plastic lotion pump of the present invention includes a fixed part 2 that is clamped at the opening of the bottle body 1, and a pump body 3 extending to the inside of the bottle body 1 is provided in the fixed part 2, and the pump body 3 is provided with a pressing part 4 for pumping the contents. The pump body 3 is provided with a pump chamber for storing the contents, the bottom of the pump chamber is provided with a first liquid inlet 31 communicating with the inside of the bottle body 1, and the top is provided with a piston piece sealed with the inner wall of the pump body 3 5. The pump cavity is provided with a one-way valve plate 6 attached to the first liquid inlet 31 , and the one-way valve plate 6 is used to open or close the first liquid inlet 31 . The pump body 3 is also provided with a plastic elastic ring 7 that is driven and stretched by the pressing part 4. The plastic elastic ring 7 is located above the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com