Leak detection device and method for fuel evaporation system

A technology of fuel evaporation system and leak detection device, which can solve the leakage of fuel evaporation system by detecting the appearance of fluid at the leak point, measuring the acceleration and deceleration rate of fluid, and using liquid/vacuum degree for liquid tightness measurement. Difficult to troubleshoot problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

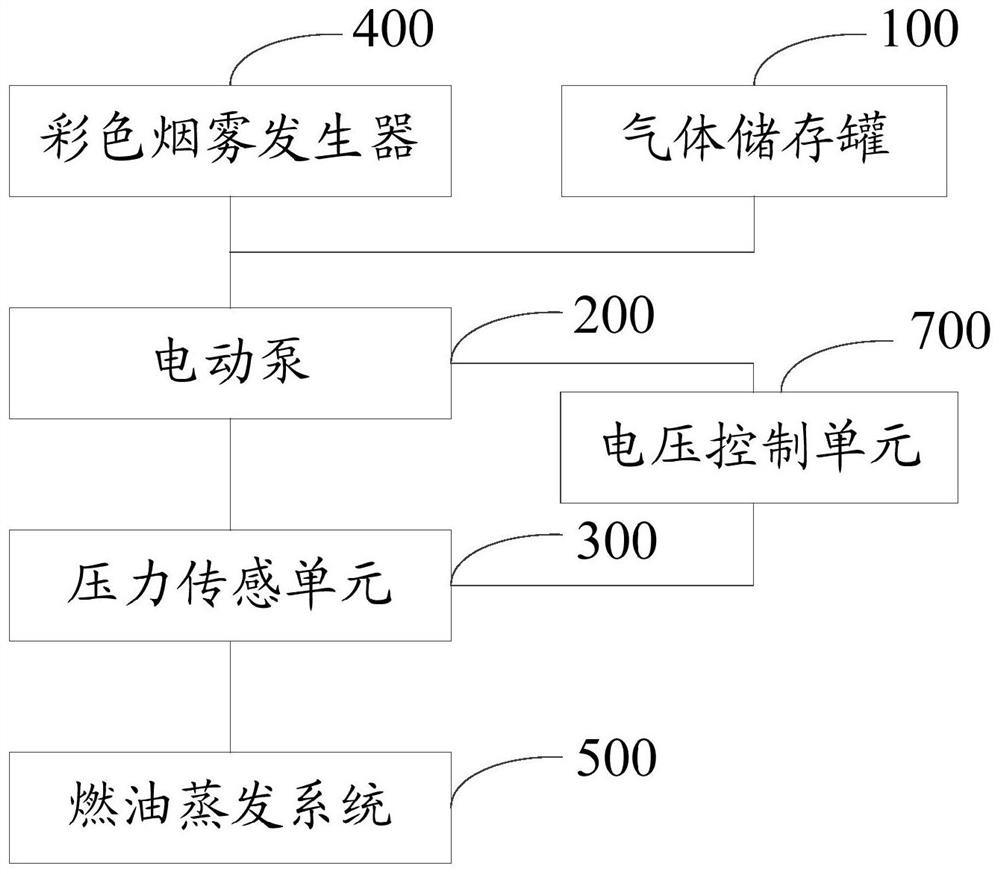

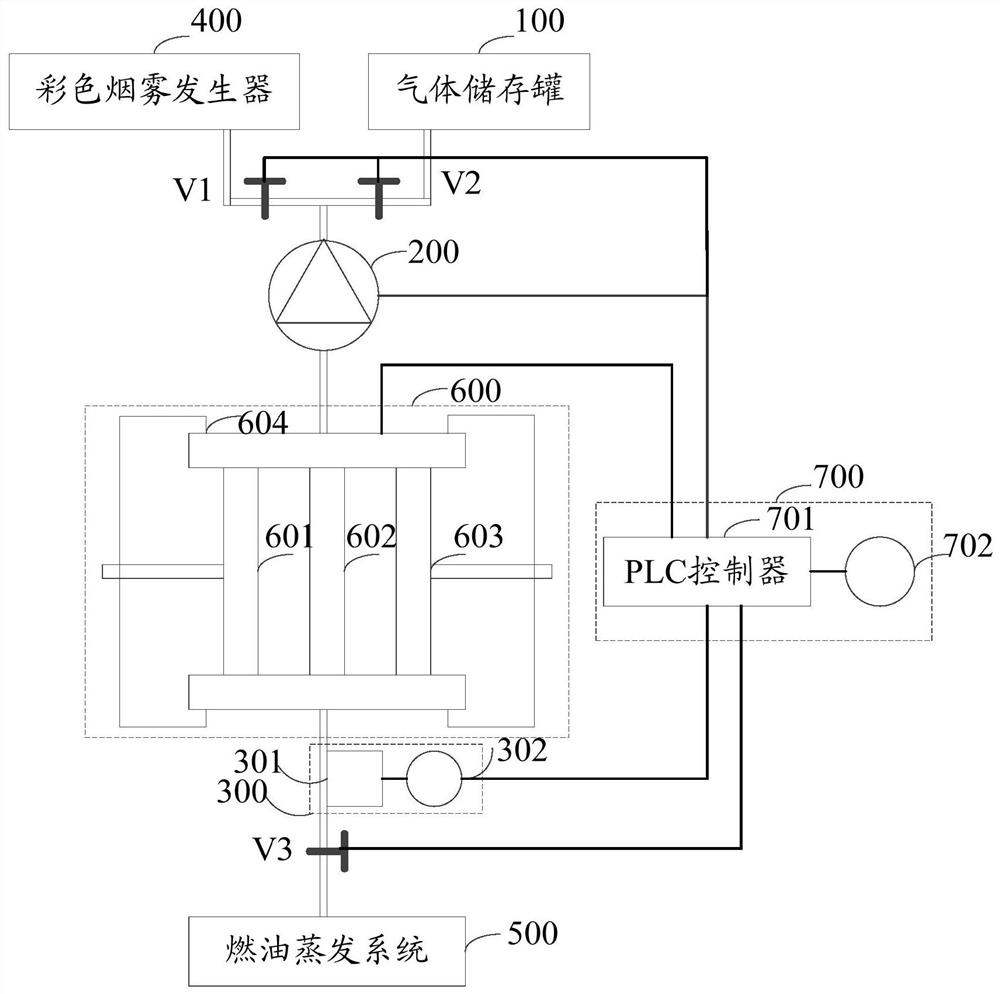

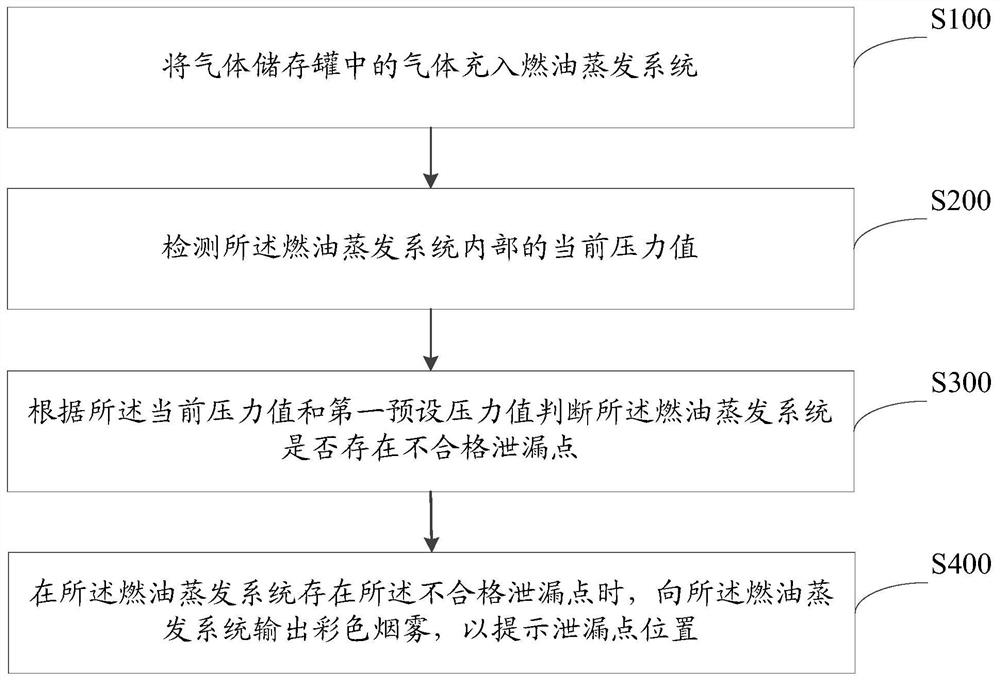

[0055] refer to figure 1 , figure 1 It is a structural block diagram of the first embodiment of the fuel evaporation system leakage detection device of the present invention; the device includes: a gas storage tank 100, an electric pump 200, a pressure sensing unit 300, a voltage control unit 700 and a colored smoke generator 400; wherein,

[0056] The input end of the electric pump 200 is connected to the output end of the gas storage tank 100 and the output end of the colored smoke generator 400, the controlled end of the electric pump 200 is connected to the control end of the voltage control unit 700 connected, the output end of the electric pump 200 is connected to the input end of the pressure sensing unit 300, the output end of the pressure sensing unit 300 is connected to the receiving end of the voltage cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com