A processing device and processing method for a preformed rod cone head

A processing method and processing device technology, which can be used in manufacturing tools, glass manufacturing equipment, etc., and can solve the problem that the shape and size of the cone head are difficult to unify.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

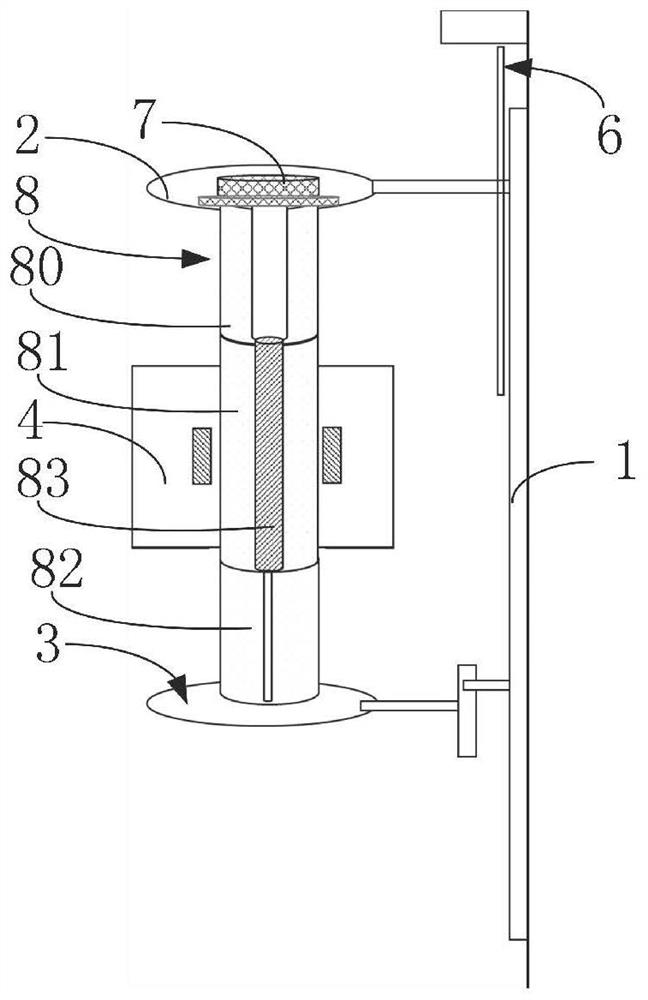

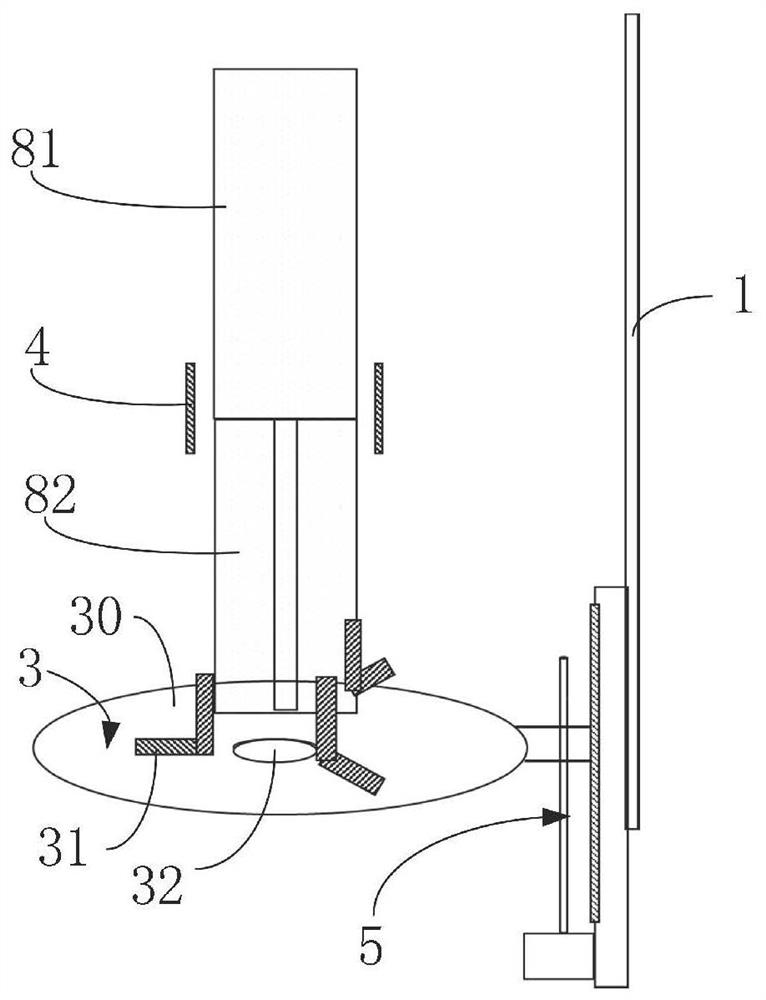

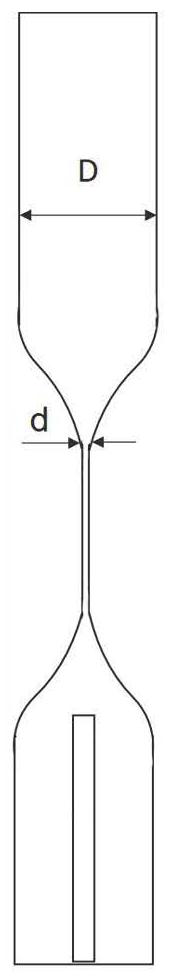

[0054] see figure 1 with figure 2 As shown, the first embodiment of the present invention provides a processing device for a preform cone, which includes a mounting plate 1, an upper clamp 2, a lower clamp 3, a heating mechanism 4, a first driving device 5 and a second driving device 6; where:

[0055] The upper clamps 2 are set on the mounting plate 1 and are used to clamp the top of the preform rod 8;

[0056] The lower clamp 3 is used to clamp or loosen the bottom of the preform rod 8, and the lower clamp 3 is movably assembled on the mounting plate 1, and is located below the upper clamp 2, and is opposite to the upper clamp 2;

[0057] The heating mechanism 4 has a heating area, which is used to accommodate and heat the preform rod 8;

[0058] The first driving device 5 is set on the mounting plate 1 and connected with the lower fixt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap