Forming mold used for washing machine drum product

A technology for washing machine drums and forming molds, which is applied in the field of injection molds, can solve problems that affect the quality of molding and demoulding efficiency, complex contours, interference, etc., and achieve high demoulding quality and demoulding efficiency, compact and reliable overall structure, and prevent The effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

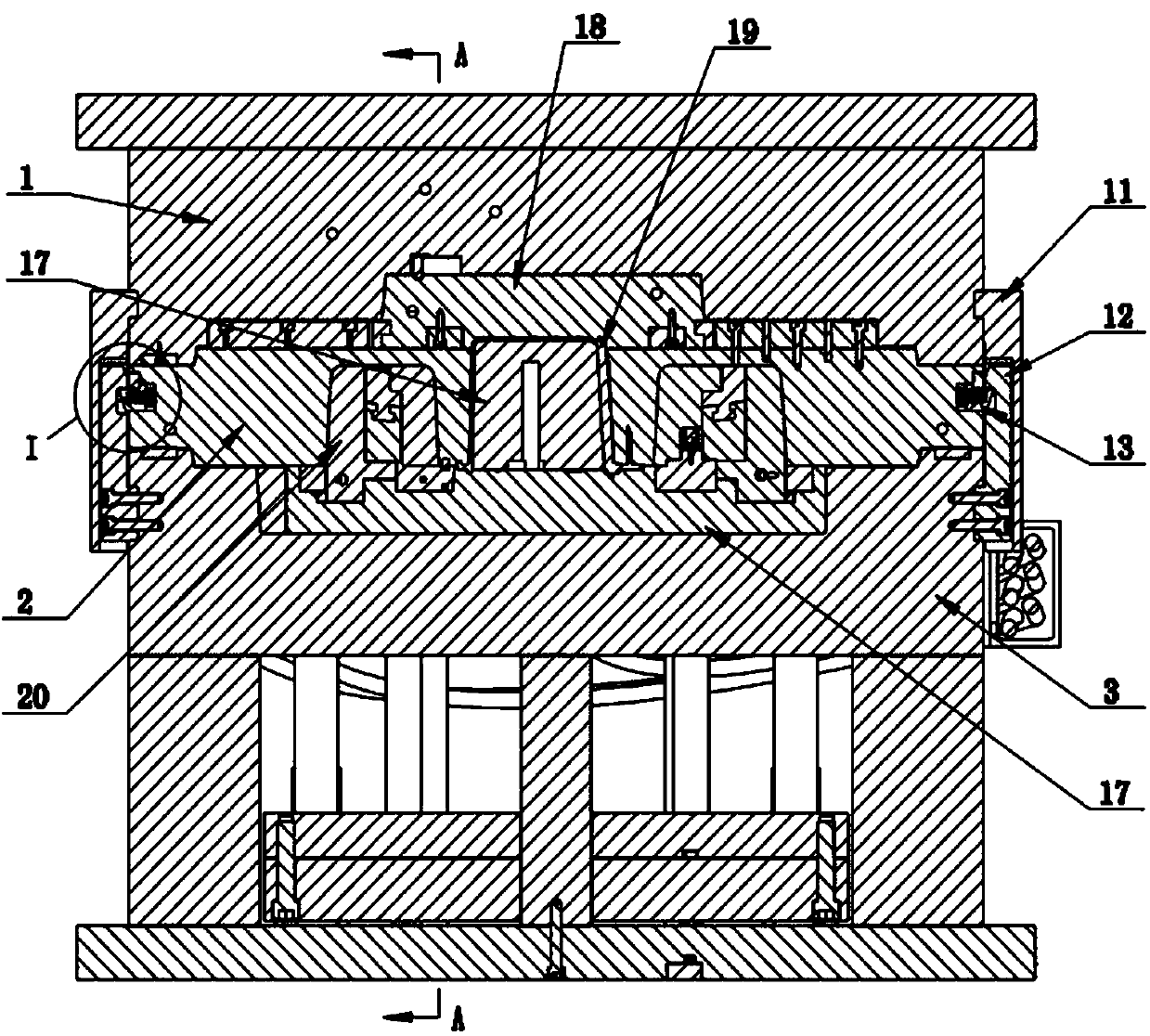

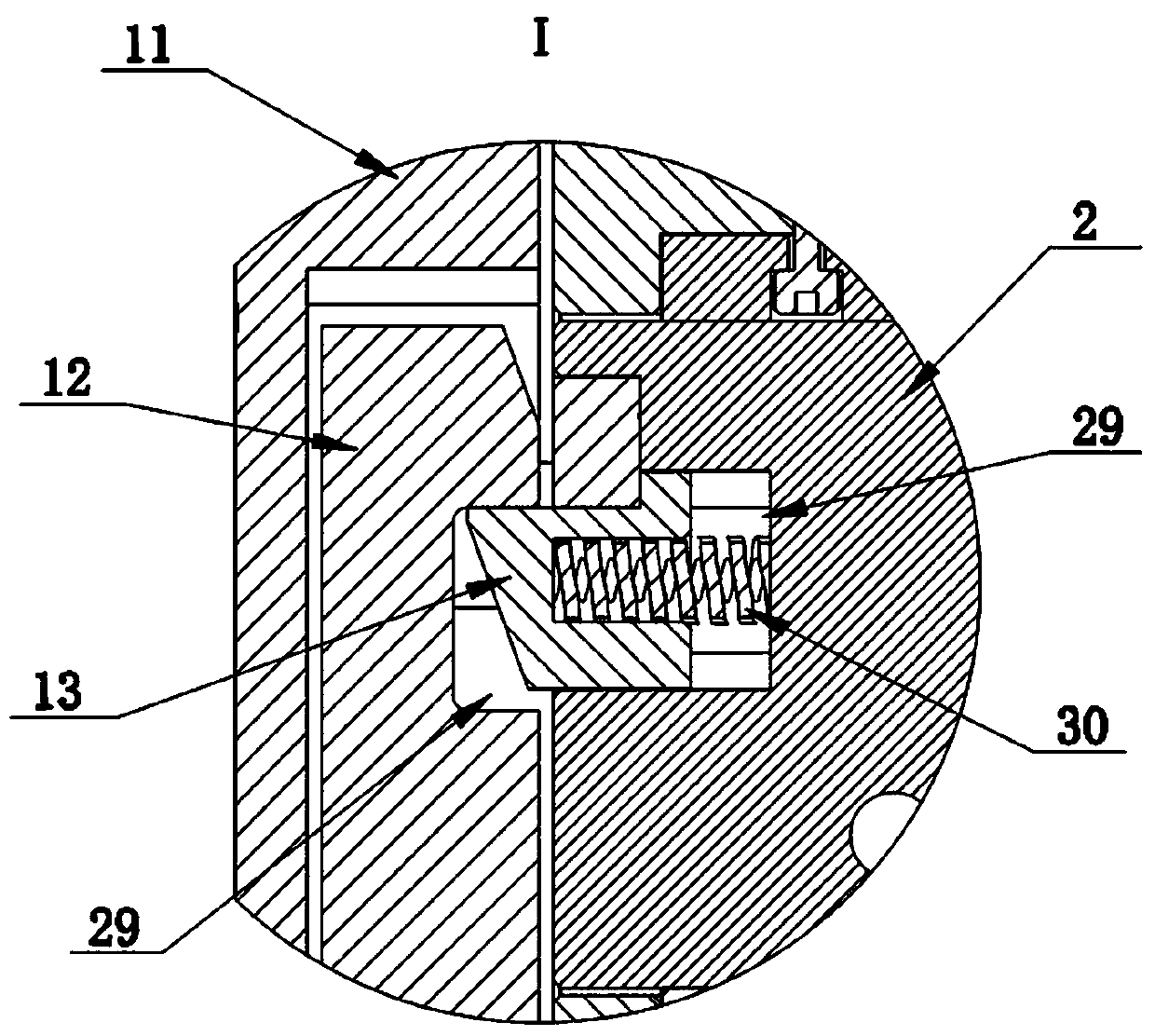

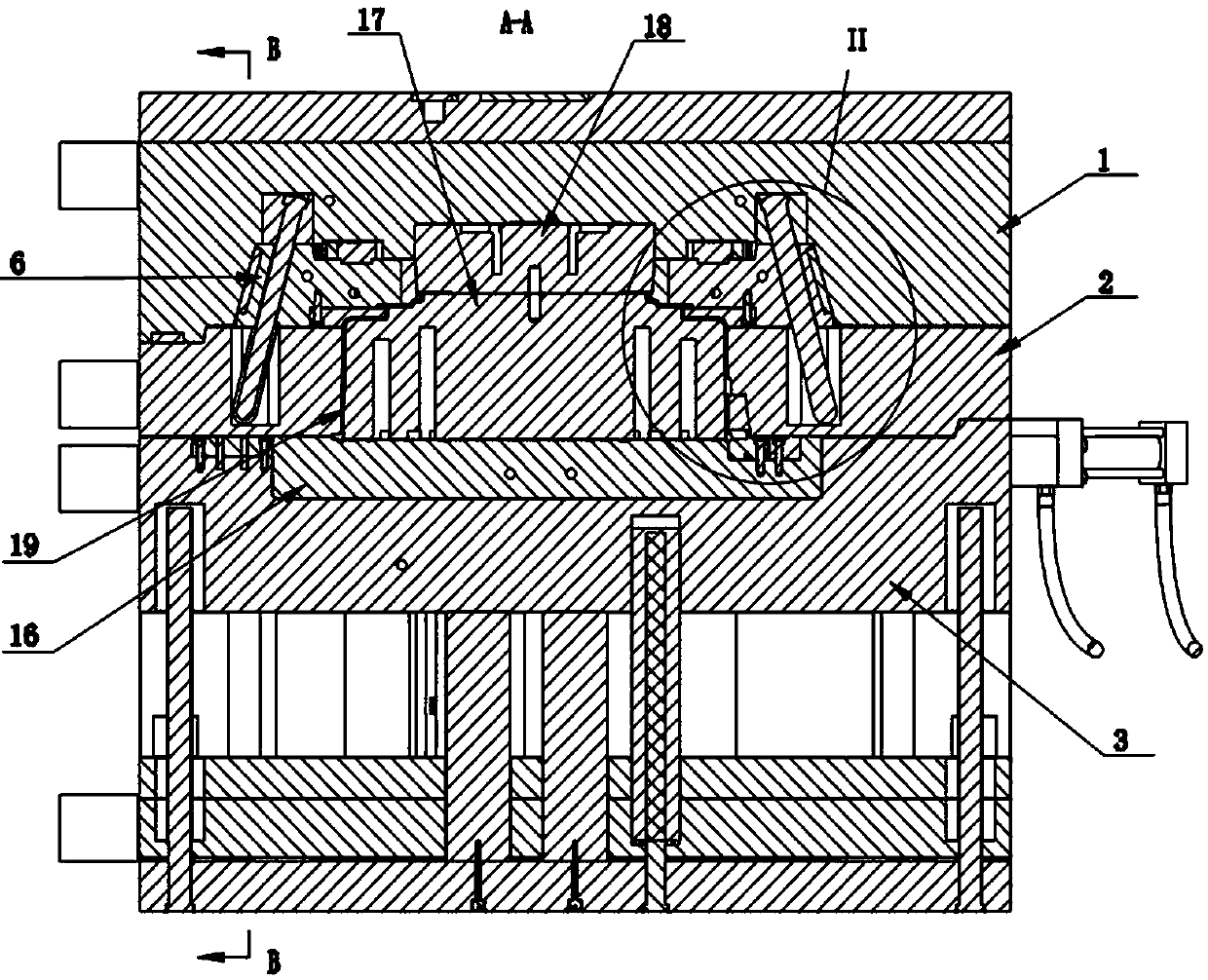

[0029] refer to Figure 1-Figure 12 , the present invention provides a molding die for washing machine drum products, comprising: a movable template 1, a middle cover plate 2 and a fixed template 3, the middle cover plate 2 is slidably installed with an upward mechanism, and the fixed template 3 is slidably installed with a downlink mechanism. position mechanism; an inclined guide column 4 is installed on the moving template 1, and the upward position mechanism includes a small row position 5 and a plurality of large row positions 6 that cooperate with the inclined guide post 4; The row-position linkage mechanism, when demolding, the large row position 6 pushes the small row position 5 to demould synchronously through the row-position linkage mechanism. The movable template 1 moves upward to demould, pushes the upward position mechanism to move horizontally to the outside through the inclined guide column 4 to demould, the large position 6 moves horizontally to the outside, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com