Paraffin discharging method for paraffin discharging dropper of tumor tissue automatic opening and closing paraffin block embedding machine

An automatic opening and closing, tumor tissue technology, applied in the preparation of test samples, etc., can solve problems such as high cost, waste, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

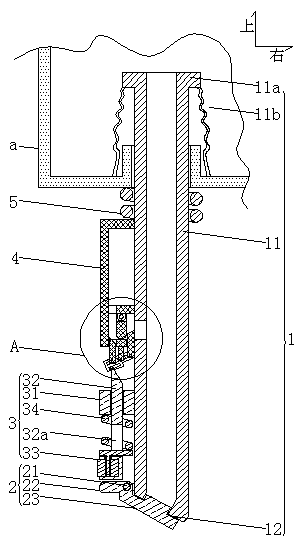

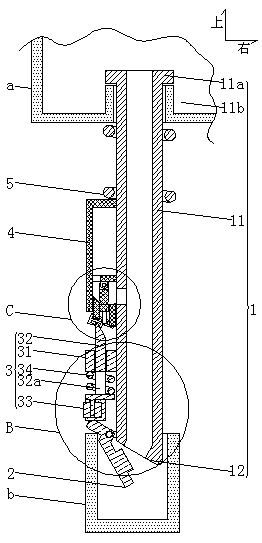

[0073] The present invention will be described in further detail below in conjunction with the accompanying drawings.

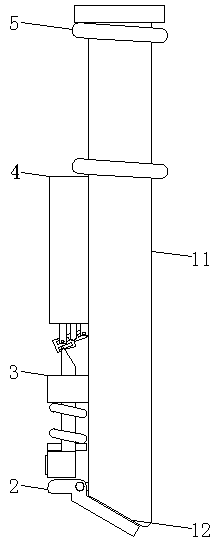

[0074] A method for discharging wax from a wax dropper of a tumor tissue automatic opening and closing wax block embedding machine, which is used to drop the liquid wax melted in the wax melting box a into the wax collection box b, and the automatic opening and closing wax block Embedding machine wax dropper includes wax dripping lumen 1, hinged bottom cover 2, linkage pull rod 3, temporary wax storage box 4, high pressure spring 5;

[0075] The wax drop lumen 1 is used to drip liquid wax into the wax collection box b, and the wax drop lumen 1 includes:

[0076] The lumen body 11 is slidably inserted into the wax melting box a;

[0077] The oblique outlet 12 is provided on the lower end surface of the lumen body 11 and is inclined from upper left to lower right;

[0078] Further, the lower end surface of the wax melting box a is inserted into the lumen body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com