Method for determining service life of bulletproof steel plate

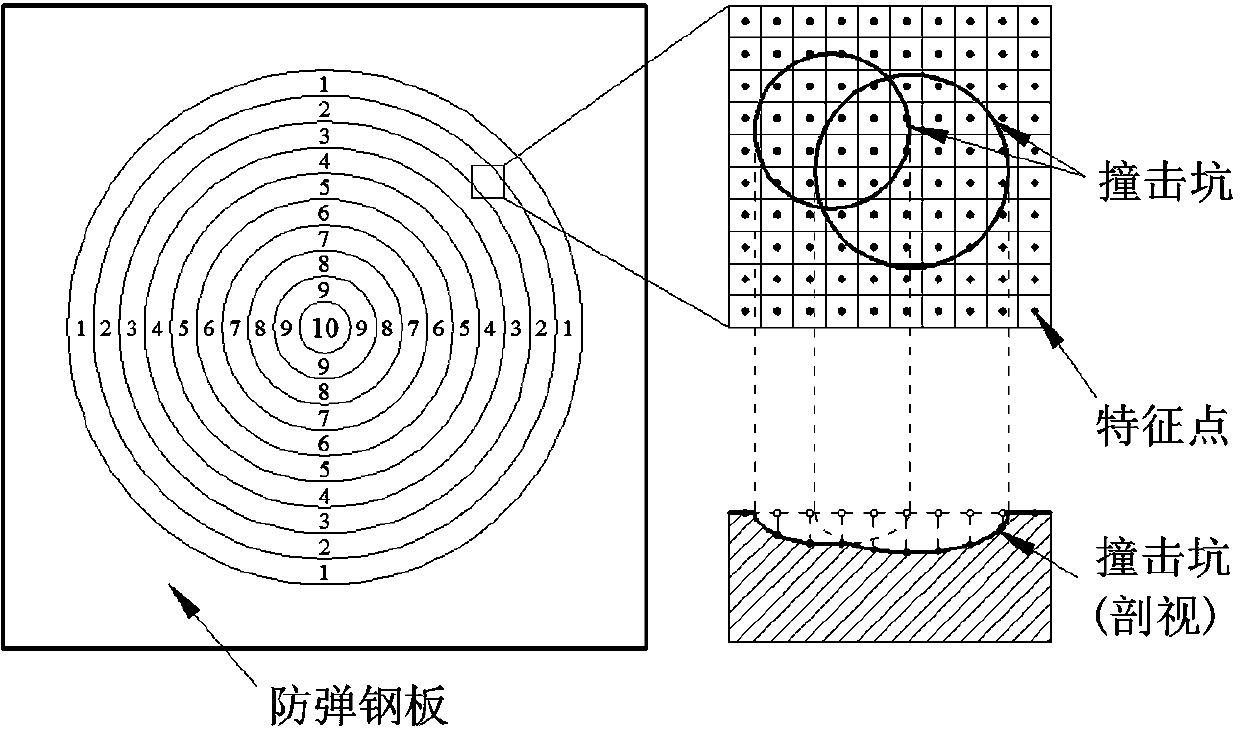

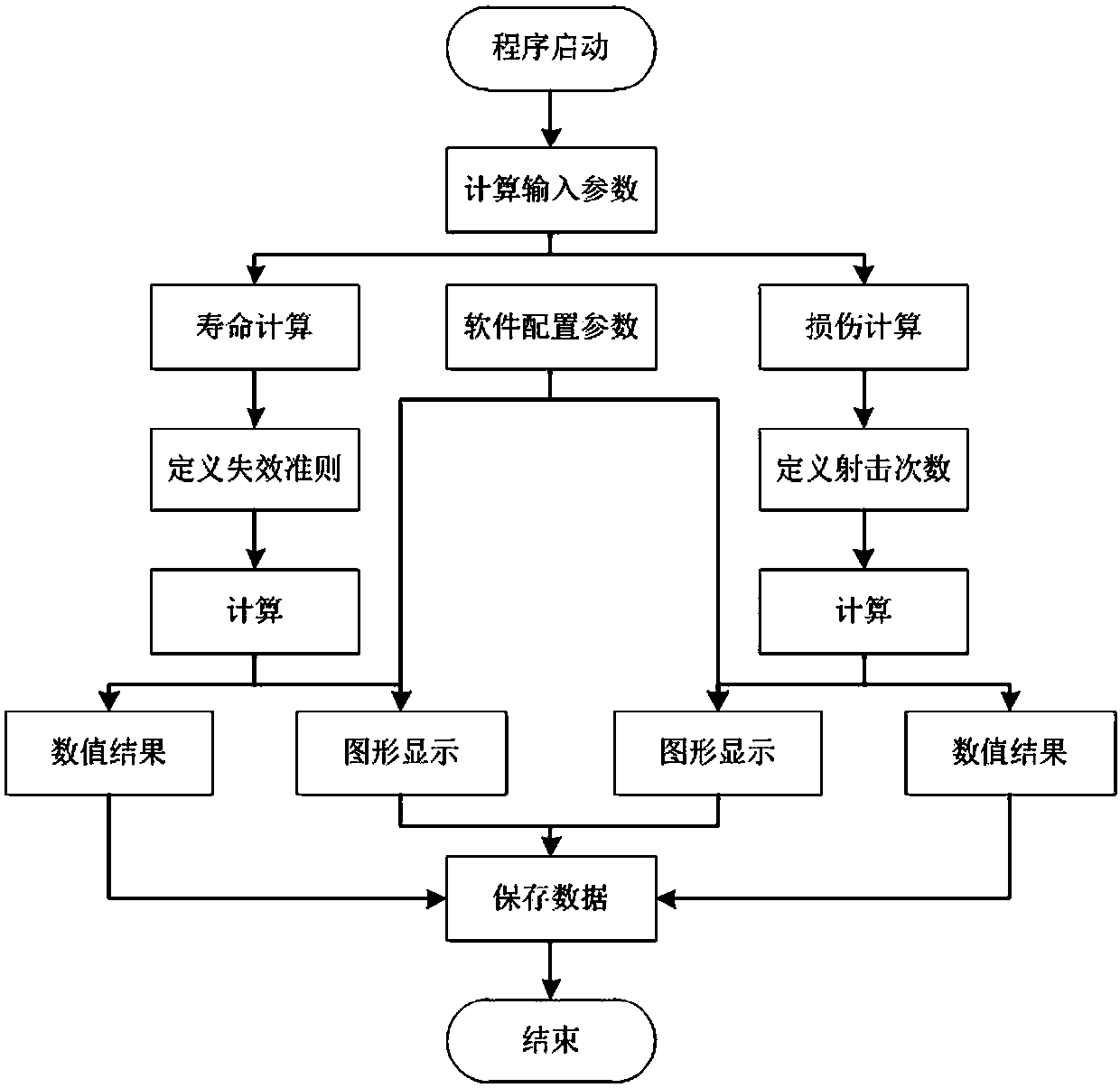

A simulation calculation, bulletproof steel plate technology, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as insufficient impact life research, and achieve the effect of simple and easy-to-understand display results, high cost-effectiveness, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

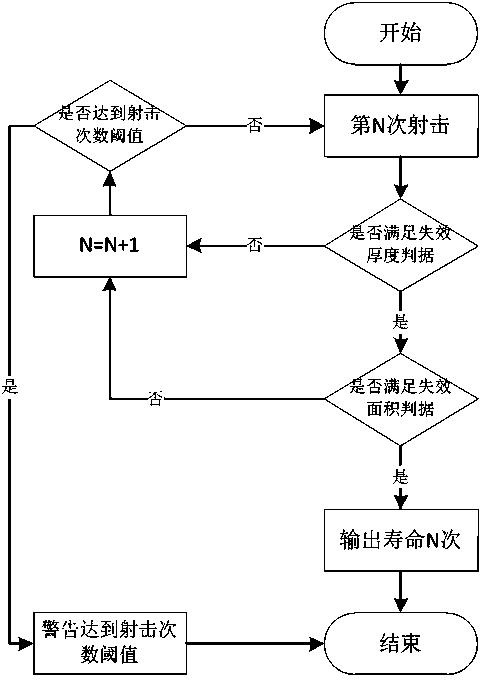

[0067] Calculate the service life of bulletproof steel plate

[0068] Such as image 3 As shown, the Nth (initial value is 1) shooting is carried out, and it is judged whether the failure thickness at the bullet impact point meets the failure thickness criterion after shooting. If the failure thickness criterion is not satisfied, it is judged whether the shooting times threshold is reached. The criterion is to judge whether the current failure area of the bulletproof steel plate satisfies the failure area criterion; if the failure area criterion is not satisfied, it is judged whether the shooting times threshold is reached, and if the failure area criterion is met, the life of the bulletproof steel plate is output N times and the calculation ends; If the shooting times threshold is reached, a warning message will pop up and the calculation will end. If the shooting times threshold is not reached, the N+1th shooting will be performed.

Embodiment 2

[0070] Calculation of damage to bulletproof steel plates

[0071] Such as Figure 4 As shown, first iterate the number of shots to the set number of shots, and then output the failure thickness at each feature point of the bulletproof steel plate, and output the total failure area of the bulletproof steel plate according to the failure thickness criterion, and judge whether the failure area criterion is satisfied. The failure area criterion judges that the bulletproof steel plate is invalid and ends the calculation. If the failure area criterion is not satisfied, it is judged that the bulletproof steel plate has not failed and the calculation ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com