Automobile plastic mold dust-proof structure

A technology of plastic molds and dust-proof structures, which is applied in the direction of cleaning methods and utensils, pollution prevention methods, chemical instruments and methods, etc. It can solve the problems of affecting the service life of molds, prone to slipping, and dusty, etc., and achieves reducing slippage. Probability of shifting, improved stability, and good dust-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

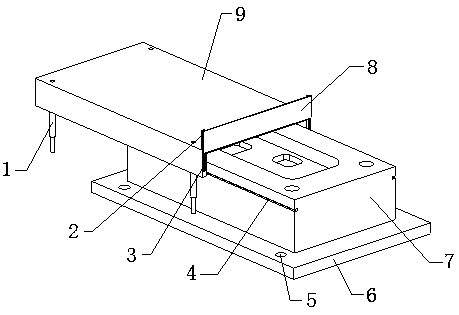

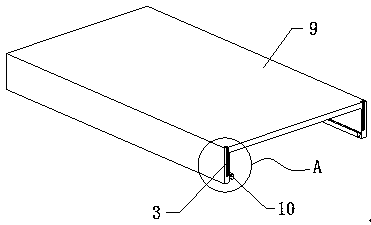

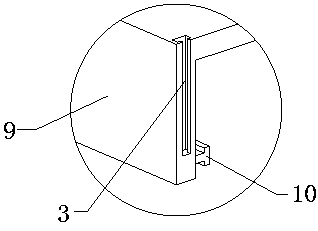

[0021] Specific implementation method: when using, two sets of T-shaped bars 10 are inserted into two groups of T-shaped slots 4 respectively, and when T-shaped bars 2 10 are fully inserted in T-shaped slots 2 4, the dust cover 9 and The installation of the mold 7 is followed by inserting two sets of T-shaped strips-2 into two sets of T-shaped grooves-3 respectively, so as to achieve the connection between the cover plate 8 and the dust cover 9, and then the dust cover 9 and the cover plate 8 work together to The upper side of the mold 7 is covered to achieve the purpose of dust prevention. When multiple groups of molds 7 need to be stacked, one group of molds 7 is placed on the upper end surface of another group of molds 7, and then the round rod 11 is pulled out from the sleeve 13, and then Pass the lower end of the round rod 11 through the through hole 5. When the length formed by the round rod 11 and the sleeve 13 meets the requirements, tighten the bolt 12, and then under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com