Efficient nonmetal-chain type mud scraper

A non-metal, scraper technology, applied in sedimentation tanks, chemical instruments and methods, separation methods, etc., can solve the problem of lack of cleaning facilities for scrapers, easy accumulation and agglomeration of scrapers, poor scraping and cutting effect of sediments, etc. The problem is to prevent the mud scraping effect from being reduced, the structure is simple, and the effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

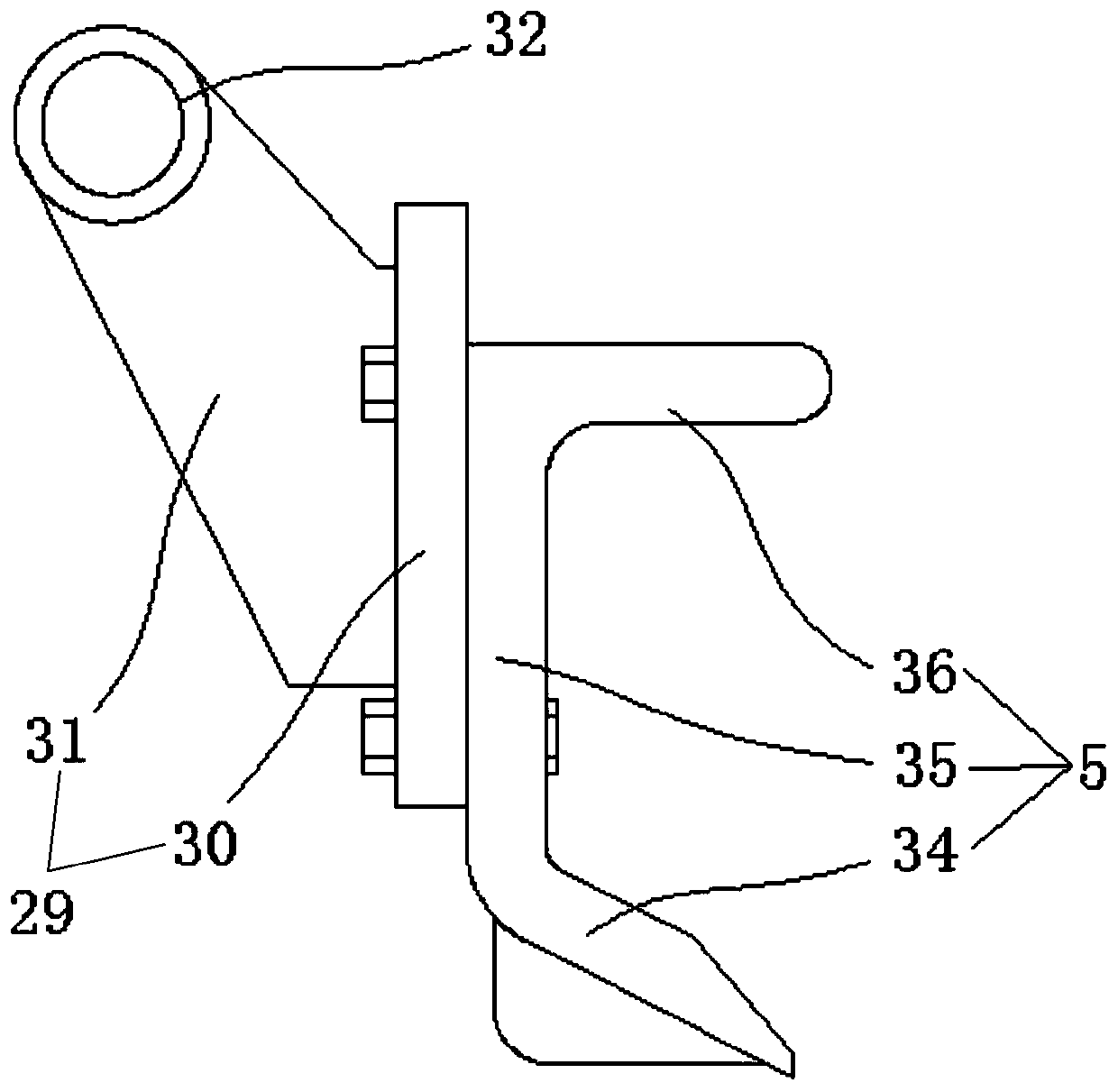

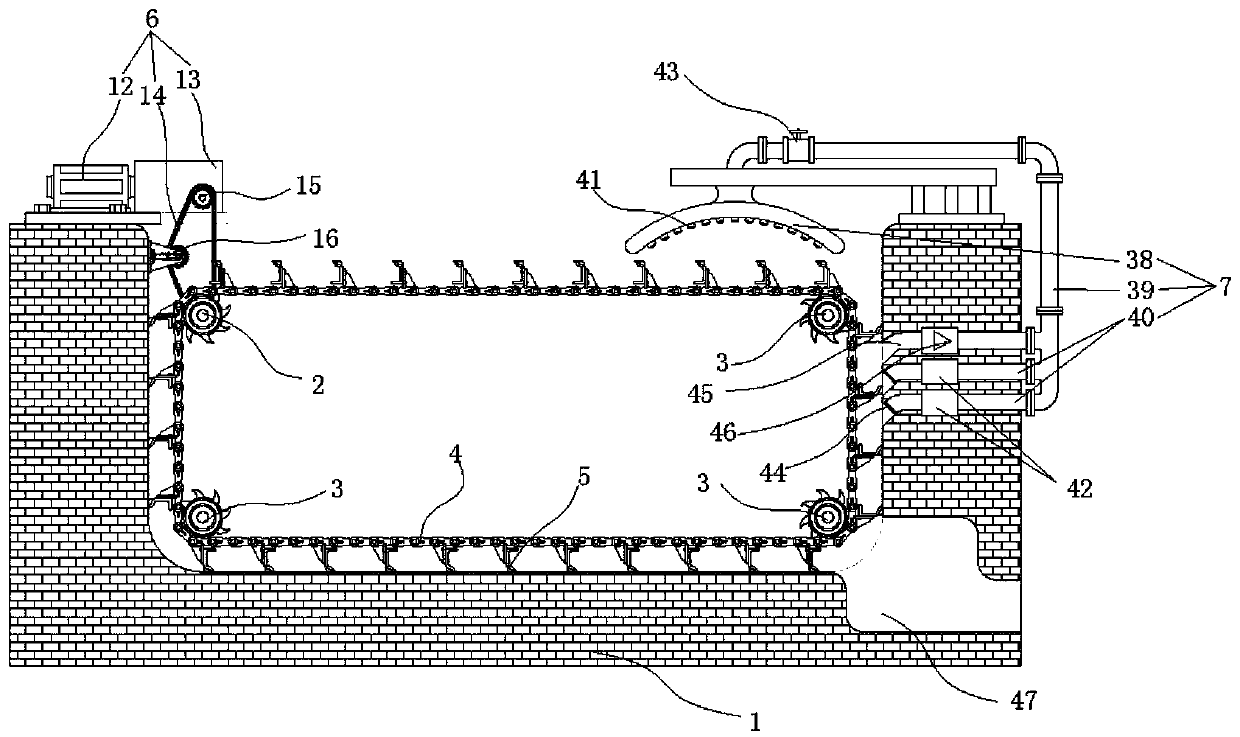

[0035] An efficient non-metallic chain scraper for dredging and scraping mud in a sedimentation tank 1, characterized in that it includes a driving shaft 2, a driven shaft 3, a scraping chain 4, a scraper 5, and a driving mechanism 6 and the cleaning mechanism 7, the driving shaft 2 and the driven shaft 3 are rotated and installed in the sedimentation tank 1, the mud scraping chain 4 is wound on the driving shaft 2 and the driven shaft 3, and the driving shaft 2 is controlled by the driving mechanism 6 Rotate to drive the mud scraper chain 4 to move, the mud scraper 5 is fixedly installed on the mud scraper chain 4, and moves with the mud scraper chain 4 to scrape mud, and the cleaning mechanism 7 is used for the mud scraper 5 and the mud scraper chain 4 rinses.

Embodiment 2

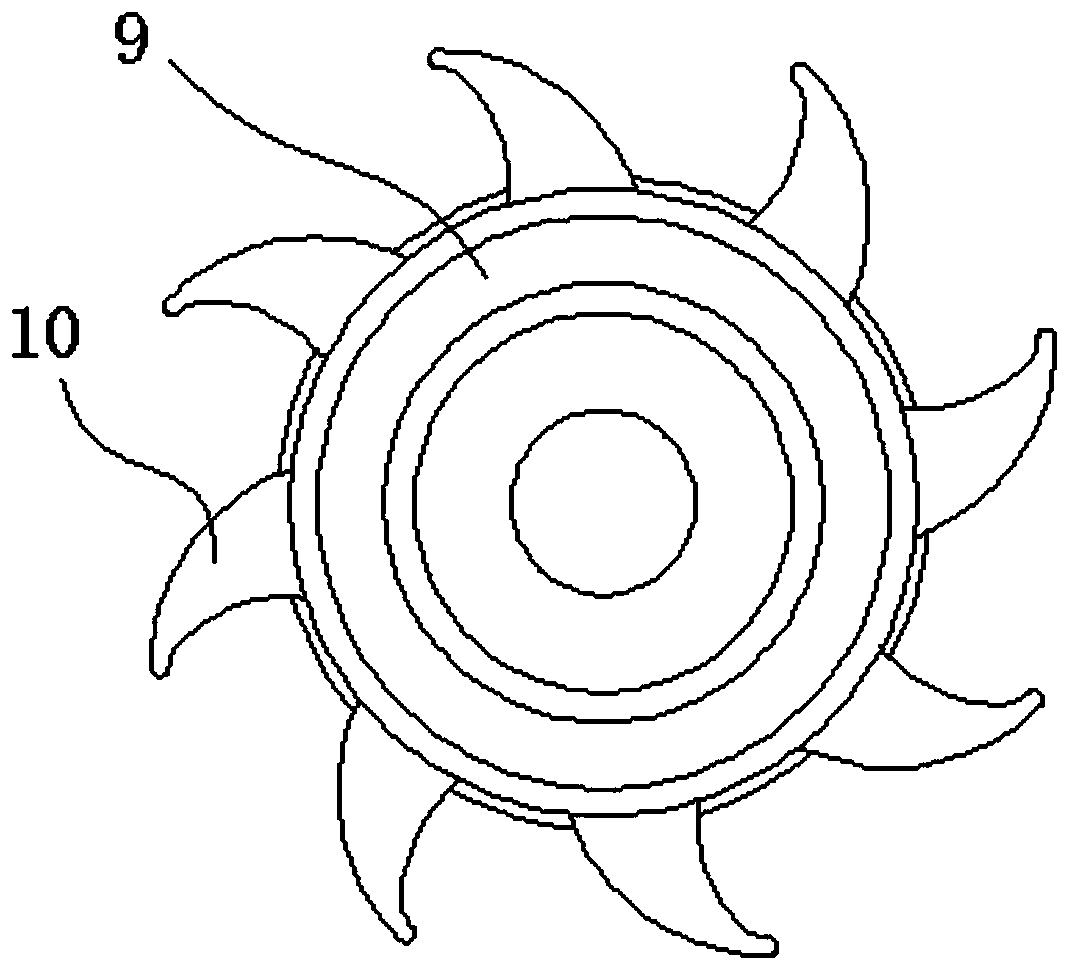

[0037] An efficient non-metallic chain type mud scraper in this embodiment, wherein, the two ends of the driving shaft 2 and the driven shaft 3 are rotated and arranged in the sedimentation tank 1 through the bearing housing 8, and are arranged horizontally and parallel; the driving shaft 2. The driven shafts 3 are fixed with mud scraping gears 9, and the mud scraping chains 4 mesh with the mud scraping gears 9, so as to be wound on the driving shaft 2 and the driven shaft 3;

[0038] The mud scraping gear 9 includes gear teeth 10, and the gear teeth 10 are in the shape of arc claws.

[0039] In this embodiment, the gear teeth of the mud scraping gear adopt an arc-shaped claw design, which can effectively improve the meshing effect between the mud scraping gear and the mud scraping chain, and improve the stability of the mud scraper movement.

Embodiment 3

[0041] An efficient non-metallic chain type mud scraper in this embodiment, wherein, the middle part of the driving shaft 2 is provided with a first gear 11, and the driving mechanism 6 includes a driving motor 12, a gear reduction box 13 and a driving chain 14 , the transmission shaft of the drive motor 12 is connected to the input end of the gear reduction box 13, and the output end of the gear reduction box 13 is fixedly connected with the second gear 15, and the first gear 11 and the second gear 15 pass through The driving chain 14 is connected, and the driving motor 12 is transmitted to the driving shaft 2 through the gear reduction box 13 and the driving chain 14 to control the driving shaft 2 to rotate.

[0042] In this embodiment, the driving motor indirectly drives the drive shaft to rotate through the gear reduction box, thereby increasing the torque and enhancing the driving force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com