Tuyere Branches for Hot Dip Coating Equipment

A technology of hot-dip plating and tuyere, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of large space requirement, damage to product quality, expensive production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

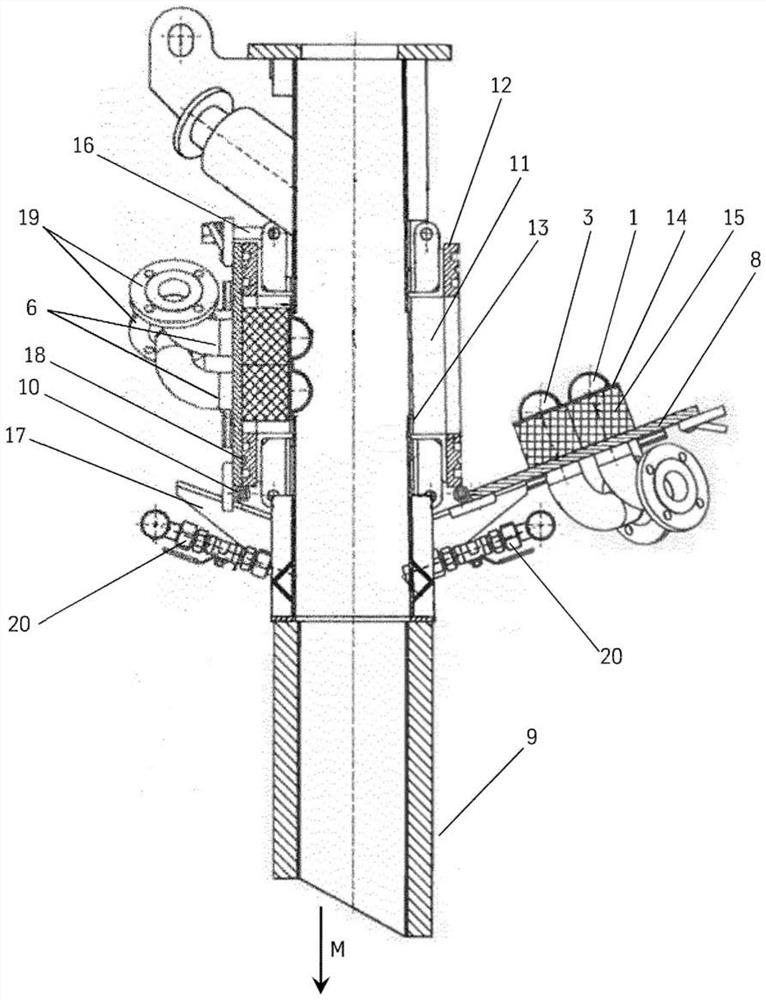

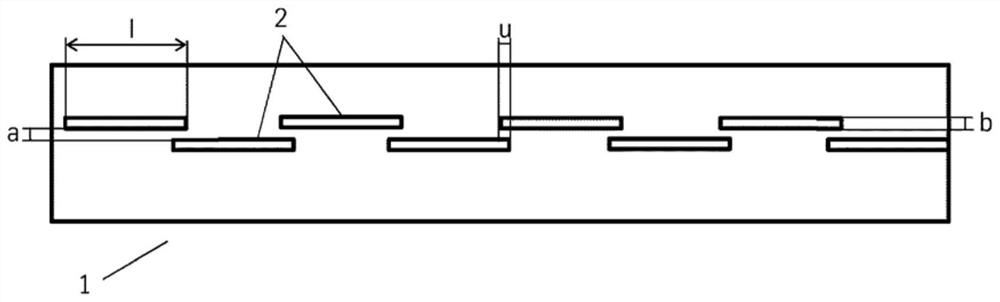

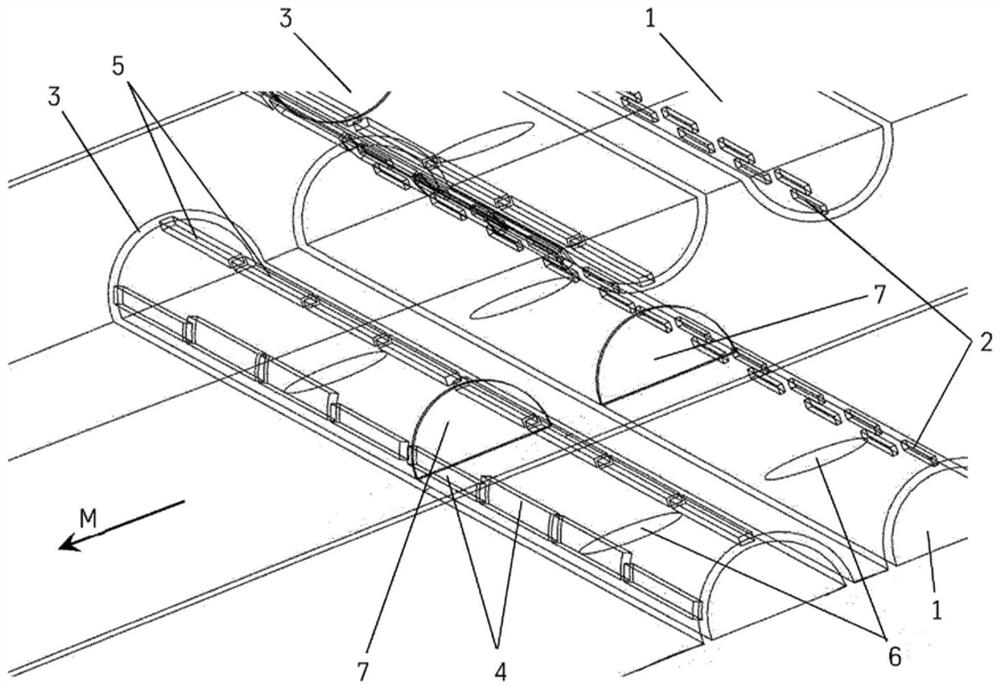

[0034] figure 1 An embodiment of the tuyere branch (9) according to the invention is shown from the side. Shown is the lower part of the tuyere branch (9) in which, in the installed state, the material flow direction (M) extends downwards from the top. The tuyere branch (9) is provided on both sides of the flat product not shown with the blowing unit (1) and the suction unit (3) extending across the width of the tuyere branch (9), where the left side is shown in the closed position , the right side is in the open position. The blowing unit (1) and the suction unit (3) are respectively arranged on the carrier plate (8).

[0035] The carrying plate (8) is movably fixed to the opposite plate (12) connected to the frame (11) by means of hinged joints (10). However, the articulated joint (10) can also be connected to the frame (11), the tuyere branch (9) or a plurality of said components. As shown, the hinged joint (10) is preferably arranged on the lower edge, viewed in the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com