Tapping gauge and using method thereof

A technology of gauge and measuring table, applied in the field of measuring equipment, can solve the problems of long inspection time, affecting construction progress, low efficiency, etc., and achieve the effect of fast processing inspection, improving work efficiency, and reducing use and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

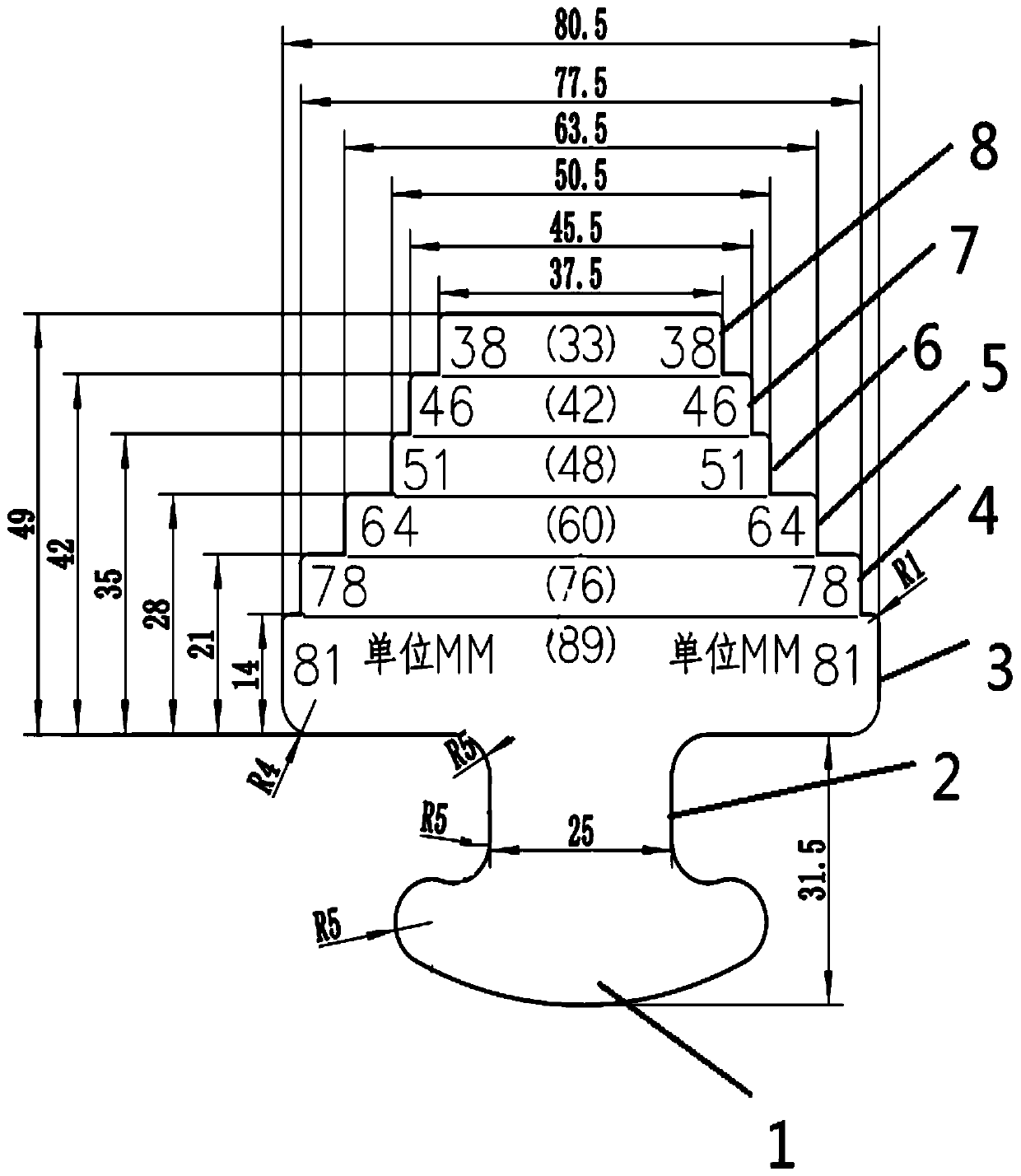

[0023] Such as figure 1 Shown, a kind of hole gauge, comprises the body of gauge, and described body comprises head and neck and measuring part, and described head and neck comprise arc-shaped head handle 1 for holding, and below the handle is for Connect the neck stem 2 of the measurement part, the bottom of the neck is connected to the measurement part, and the measurement part is stepped into at least six layers of measurement platforms from top to bottom, and the length of each layer of measurement platforms decreases from top to bottom. The surface of the floor measuring table is provided with a scale groove, and the scale groove is engraved with a scale value representing the length of the floor measuring table. From top to bottom, the measuring platforms are the first measuring platform 3, the second measuring platform 4, the third measuring platform 5, the fourth measuring platform 6, the fifth measuring platform 7, and the sixth measuring platform 8; the first measuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com