Spring leaf and method for producing a spring leaf

A technology of leaf spring and leaf spring, which is applied in the field of spring leaf and used in the manufacture of spring leaf, can solve the problems of costly leaf spring weight, expensive, process technology consumption, etc., and achieve consumption, energy and manufacturing costs, and hole breakage Effect of risk reduction and improvement of local life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

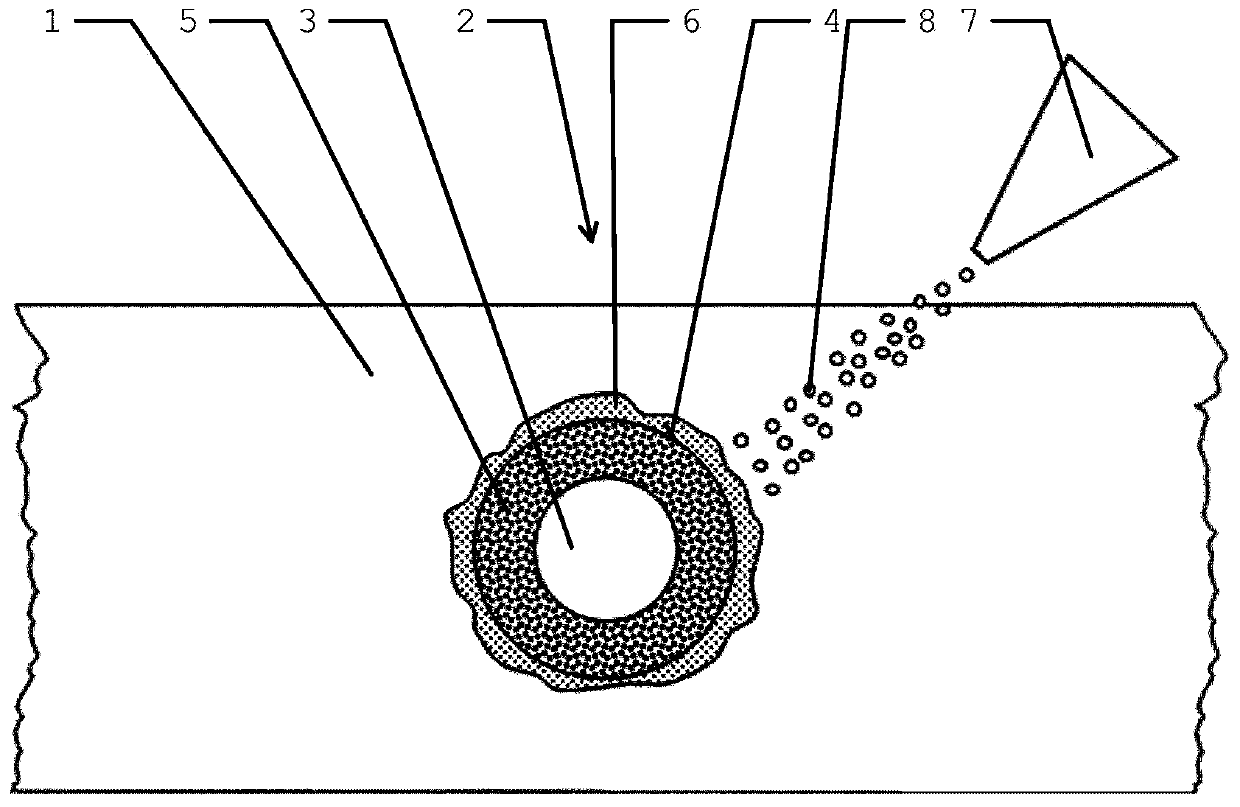

[0037] exist figure 1 The region of the underside 1 of the leaf spring 2 for the leaf spring is shown in , in which a hole 3 is made. The leaf springs can be, for example, parabolic springs or suspension springs. The hole 3 can be a through hole or a blind hole. The bore 3 can be a central bore provided in the clamping region or provided in another region of the leaf spring 2 , for example in the end region. The underside 1 of the leaf spring 2 is under compressive stress in the operating state of the leaf spring.

[0038] The leaf spring 2 is preferably made of flat bar steel, especially spring steel. The underside 1 of the leaf spring 2 is locally blasted, in particular blasted, in the region around the hole 3 . The distance from the hole 3 to the transition 4 between the sprayed and the unsprayed surface of the underside 1 is in the range of a few centimeters. During spraying, a first zone 5 is produced around the hole, which is sprayed uniformly, and a second zone 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com