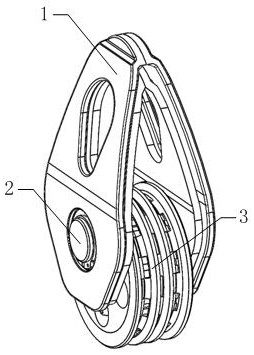

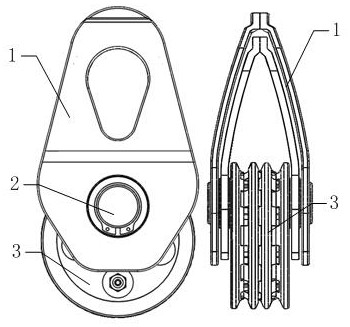

a multi-line pulley

A pulley, fixed pulley technology, applied in belts/chains/gears, portable lifting devices, transmission parts, etc., can solve the problems of not being on the center plane of the pulley, the cantilever is thin, the steel rope is stuck, and the service life is long. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are illustrative of the invention or the drawings, but are not intended to limit the scope of the present invention.

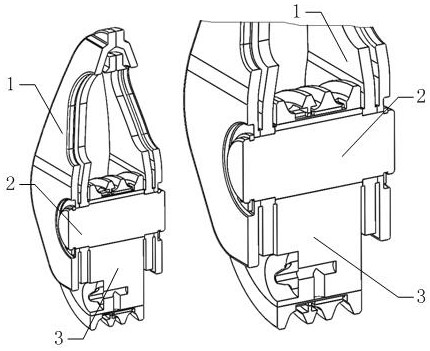

[0037] like figure 1 , 2 , The pulley mechanism that comprises three supply rope is wound, the stationary sheave mounting means 3 and the traction rope pulley boom 1, a pulley connected to the pin 3 and the pulley means of the boom 1 2, wherein: as Figure 9 Shown, the pulley wheel 10 by the mounting mechanism 3, wheel 11 is mounted and composed of two slip rings 20, as image 3 , The mounting wheel 10 is eccentrically mounted on the pin 2, the wheel 11 is mounted rotatably by nested fitting in mounting the outer mounting ring 10, two slip rings 20 mounted on the mounting nest wheel 11, and two slip rings 20 can slide back and forth on the axis of the wheel 11 is mounted in the mounting of the wheel 11; such as Figure 4 , 5 Shown, the pulley 1 by the cantilever two symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com