Buffering type steel wire rope stranding device

A technology of steel wire rope and buffer sleeve, which is applied in the field of buffer type wire rope twisting device, which can solve the problems of inconvenient operation efficiency and the inability to change the number of steel wires for twisting strands, and achieve the effects of flexible use, wide range of use, and avoiding bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

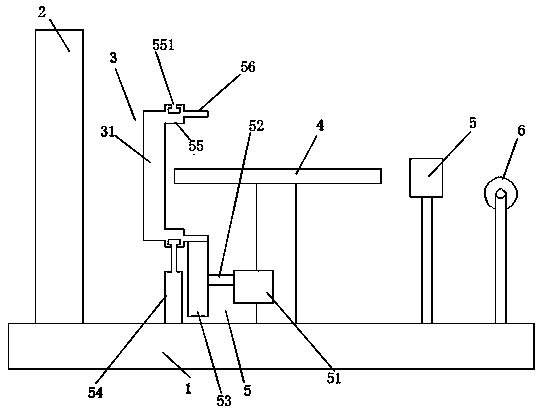

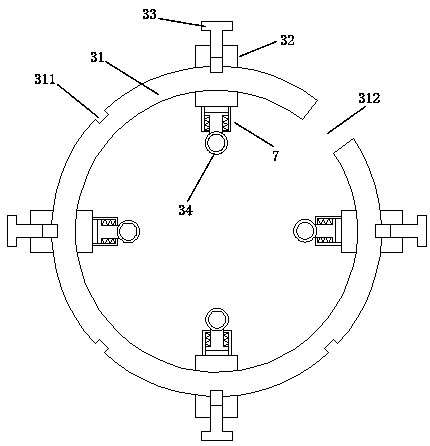

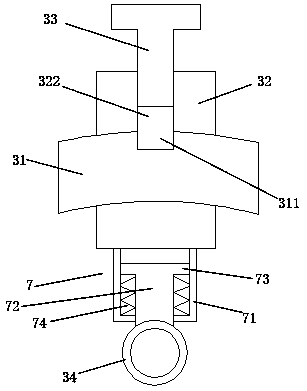

[0020] like Figures 1 to 5 As shown, a buffer type wire rope twisting device includes a base 1, a wire frame 2, a twisting mechanism 3, a driving mechanism 5, a wire pipe 4, a crimping die 5, a winding roller 6, and a buffer mechanism 7. The wire stand 2, the strand twisting mechanism 3, the cable routing pipe 4, the crimping die 5, and the winding roller 6 are sequentially installed on the base 1; the strand twisting mechanism 3 includes a rotating ring 31, a sliding socket block 32. Lock screw 33, wire routing ring 34; the drive mechanism 5 is installed on the base 1; the drive mechanism 5 controls the rotation of the rotating ring 31; the rotating ring 31 is provided with an insertion The gap 312 is convenient for the socket entry of the sliding socket block 32; a plurality of locking grooves 311 are uniformly distributed around the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com