Fluid pressure stabilizing valve with end cover sealing support structure

A support structure and sealing structure technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of pressure reducing valve function failure, pressure reducing valve gaskets are easy to fall off, etc., to ensure stable pressure and ensure working stroke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

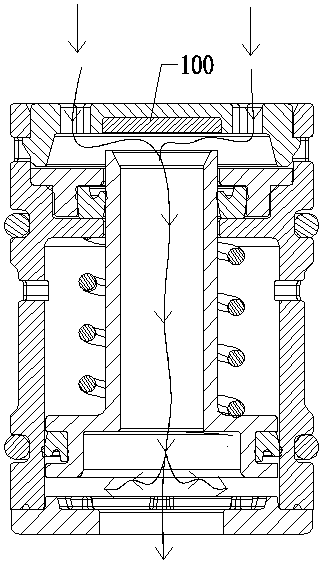

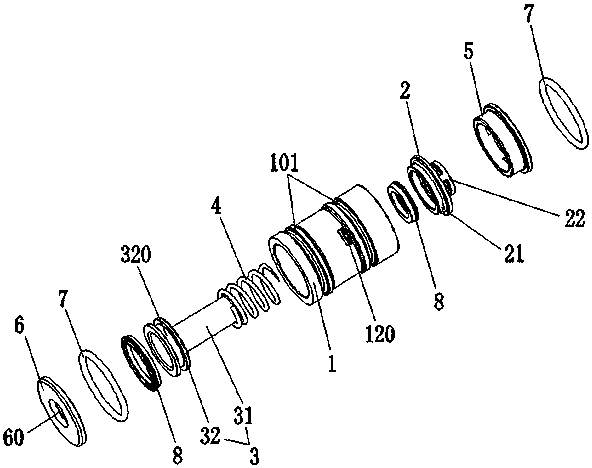

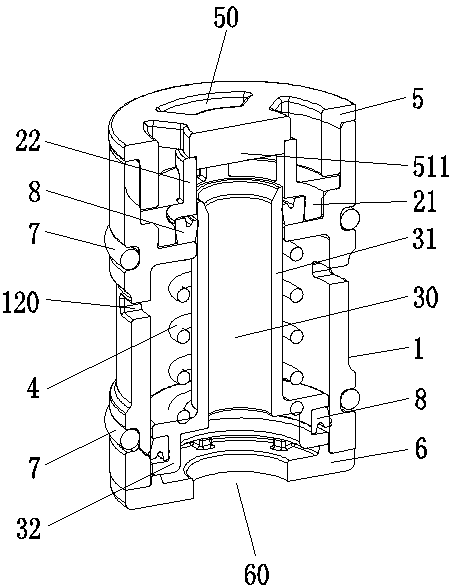

[0028] Such as Figure 2-8 As shown, a fluid pressure stabilizing valve with an end cover sealing support structure includes a hollow valve body 1, a support seat 2, a valve core 3, an elastic body 4, an upper end cover 5, an end cover sealing support structure and a lower end cover 6. The elastic body 4 is a spring or rubber or other elastic parts, and the upper end cover 5 is made of an elastic sealing material, preferably one of NBR, TPR, TPE, and EPDM. The upper end cover 5 is fixed on the upper end of the hollow valve body 1 by means of threaded connection or the like, and several water inlet holes 50 are opened on the upper end cover 5 along the circumferential direction, and the lower end cover 6 is fixedly installed on the lower end of the hollow valve body 1 by means of threaded connection or the like. , A water outlet hole 60 is opened on the lower end cover 6 . The upper and lower parts of the outer wall of the hollow valve body 1 are each provided with an O-ring g...

Embodiment 2

[0036] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the sealing structure is a sealing gasket 512, a gasket groove 510 is opened at the center of the bottom of the upper end cover 5, and the sealing gasket 512 is fixedly installed in the gasket groove 510 , the upper surface of the support ring 22 bears against the gasket 512 . The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0037] The working principle of this embodiment is:

[0038]Initial state: the fluid flows in from the fluid inlet end, flows into the bottom position of the valve core 3 through the water flow channel 30 of the valve core 3 , and the fluid pressure exerts an upward force on the valve core 3 . There is a pre-pressure F1 on the elastic body 4 during installation, and when the fluid pressure F2 is less than F1, it is not enough to push the valve core 3 to move, and the valve core 3 remains in the initial state.

[0039] Dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com