Double-clamping mechanism of machining center

A clamping mechanism and clamping cylinder technology, applied in metal processing machinery parts, metal processing equipment, clamping and other directions, can solve the problems of small effective space and poor processing accuracy, and achieve convenient conversion, simple device structure, and travel space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

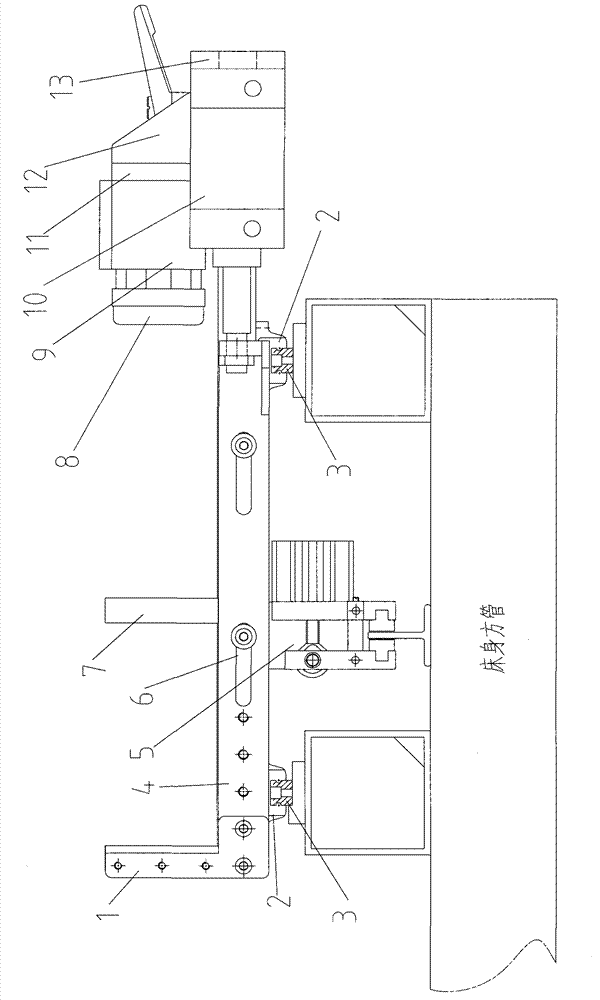

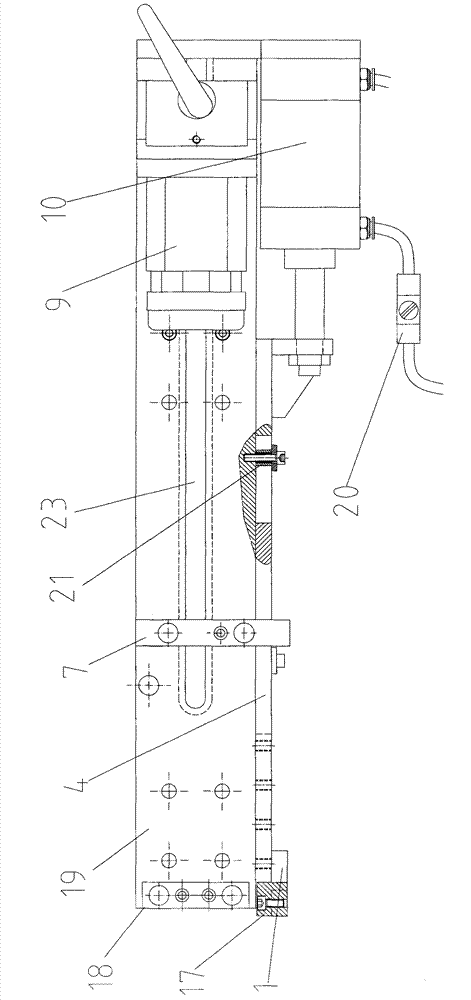

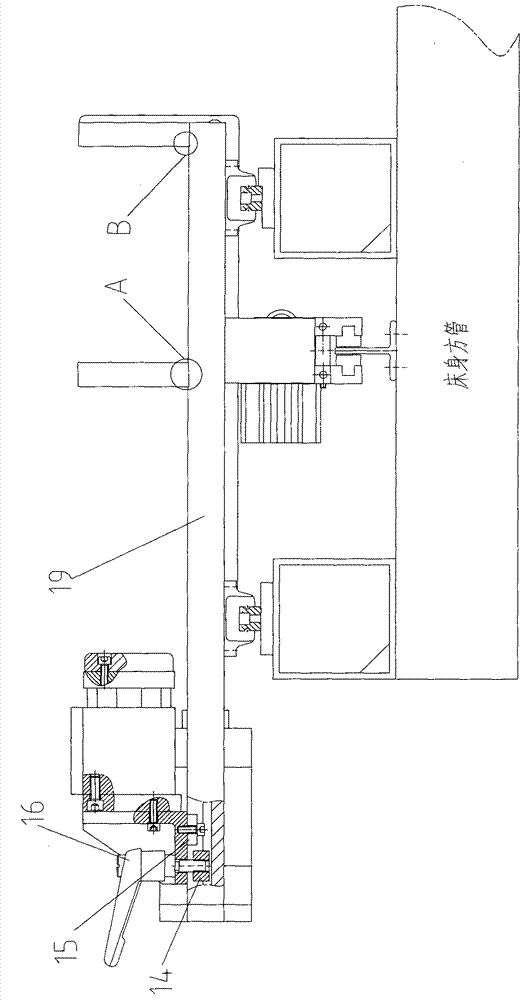

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a double clamping mechanism of a machining center is mainly composed of a fixture seat 19. The fixture seat 19 is connected and fastened to two linear sliders 2, a brake device 5, an intermediate fixed seat 7 and a fixed seat 18 through screws. Together, the two linear sliders 2 can move linearly along the two linear guide rails 3 installed on the bed square tube of the machining center, and the brake device 5 plays the role of fixing the position of the clamp; the upper plane of the clamp seat 19 is provided with a sliding length Slot 23, insert T-type nut 14 in the sliding long groove 23, T-type nut 14 is connected with locking handle 16 and fix cylinder support 12 on the clamp seat 19, cylinder support 12 is connected with cylinder mounting plate 11 and clamping Cylinder I9, loosen the locking handle 16 to move the position of the clamping cylinder I9 to adapt to the size of the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com