Shear fork lifting table of wall painting machine

A lifting platform and scissor technology are applied in the field of wall painting machines, which can solve the problems of difficult handling, limited use places, shortening the frame, etc., and achieve the effect of increasing the flexibility of use and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

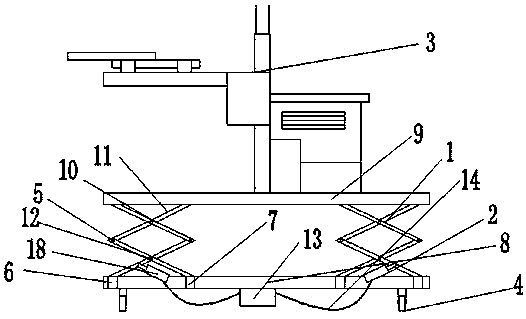

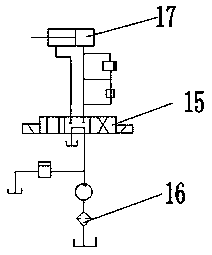

[0014] like figure 1 The scissor lifting table of a wall painting machine shown includes a mechanical mechanism 1, a hydraulic system 2, a painting frame 3 and a universal wheel 4, and is characterized in that the above-mentioned mechanical structure 1 includes a living hinge 5, an underframe beam a6, underframe beam b7, base 8, table top 9, outer scissor arm 10, inner scissor arm 11, connecting rod 12, above-mentioned painted frame 3 is fixedly connected with above-mentioned table top 9, the bottom of the framework of above-mentioned base 8 is provided with The above-mentioned universal wheel 4, the above-mentioned underframe beam a6 and the above-mentioned underframe beam b7 are respectively fixed on the frame of the above-mentioned base 8, the above-mentioned outer scissor arm 10 is fixed on the above-mentioned underframe beam a6 through the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com