Cam ejecting mechanism

A technology of ejecting mechanism and cam mechanism, which is applied to conveyor objects, transportation and packaging, etc., can solve the problem that the length accuracy of the workpiece cannot be guaranteed, and achieve the effects of simple structure, high working reliability and strong use versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

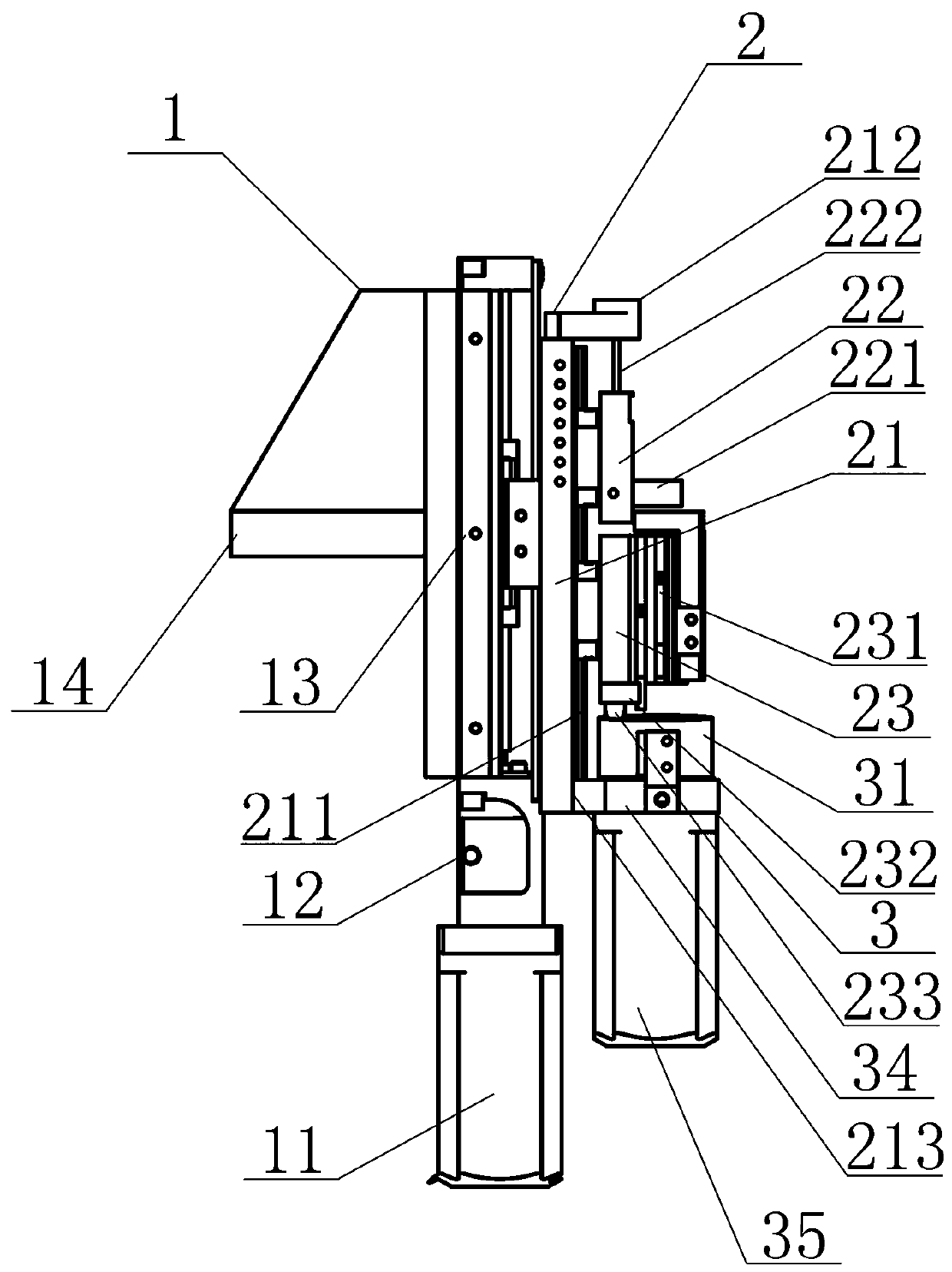

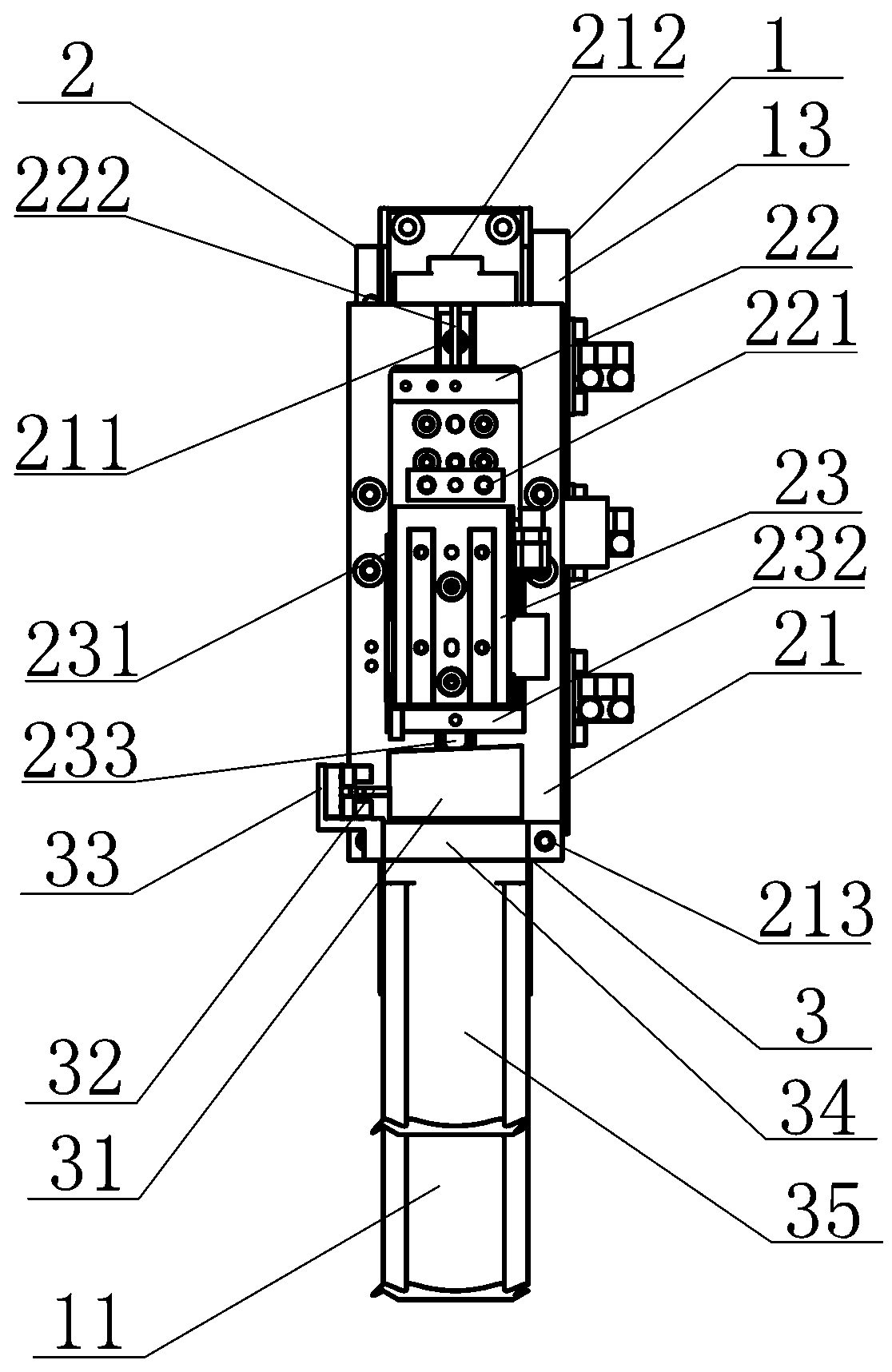

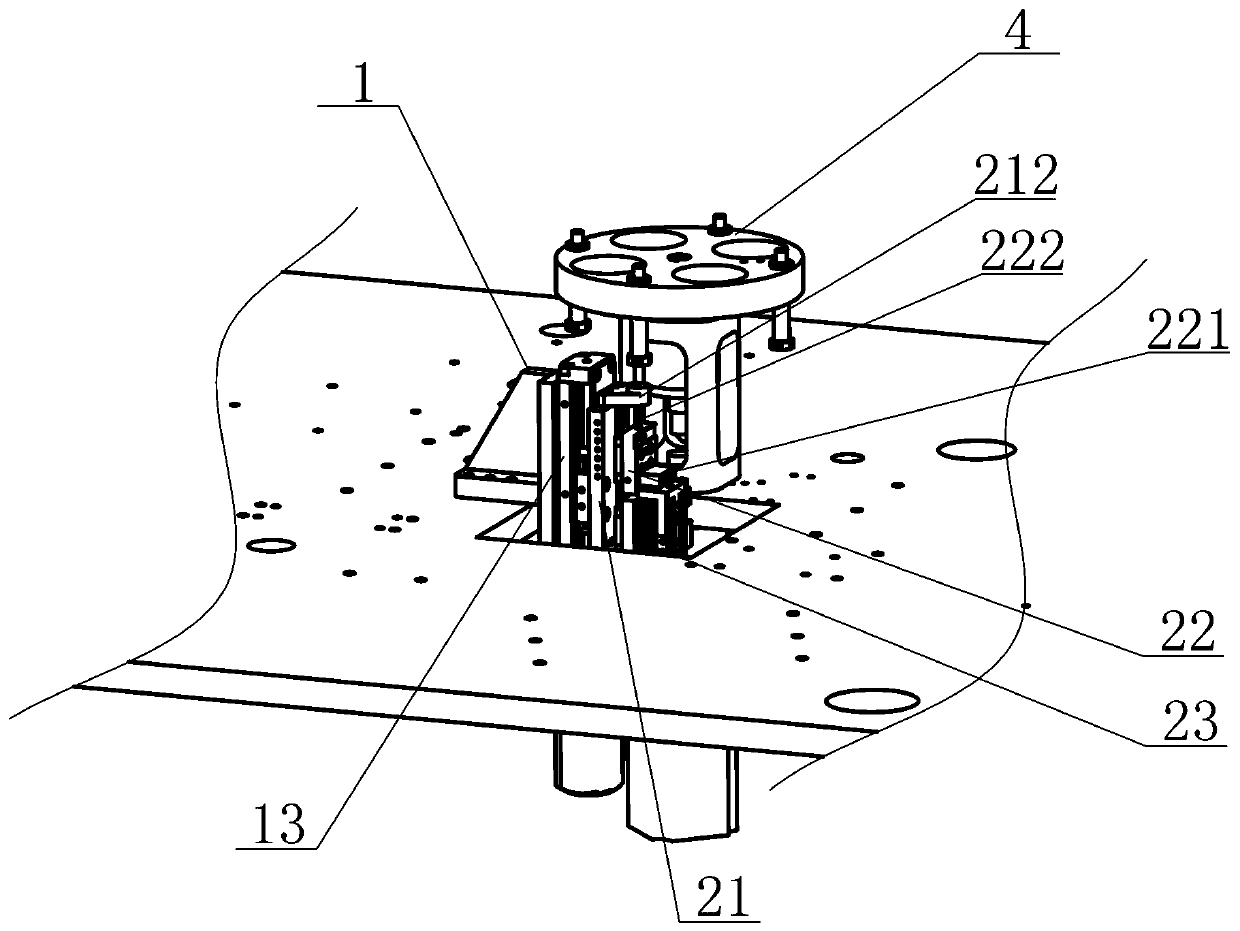

[0020] Refer to figure, figure 2 , the present invention includes a propulsion mechanism 1, a material ejection mechanism 2, and a cam mechanism 3;

[0021] Described propulsion mechanism 1 is made of module driving motor 11, module 12, module mounting plate 13, propulsion mechanism fixing plate 14, and described module mounting plate 13 is arranged on the propulsion mechanism fixing plate 14, and module 12 is located at On the module mounting plate 13, the bottom of the module 12 is provided with a module drive motor 11, and the module mounting plate 13 is provided with a drive slider;

[0022] The ejector mechanism 2 is composed of a guide rail mounting plate 21, a push rod mounting plate 22 and a cylinder mounting plate 23. One side of the guide rail mounting plate 21 is provided with a linear guide rail 211, and the other side is provided with a drive slider seat, and the guide rail mounting plate The top of 21 is provided with ejector sleeve 212, and the bottom is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com