Production method of cable with small bending radius

A technology of bending radius and production method, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., and can solve problems such as wear and tear, and the center of the insulating layer and the conductor cannot be concentric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

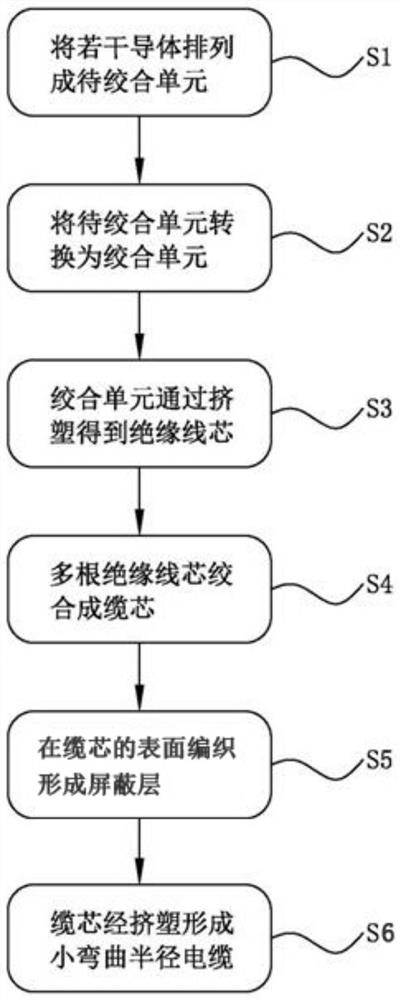

[0041] Such as figure 1 Shown, the production method of small bending radius cable of the present invention, comprises the following steps:

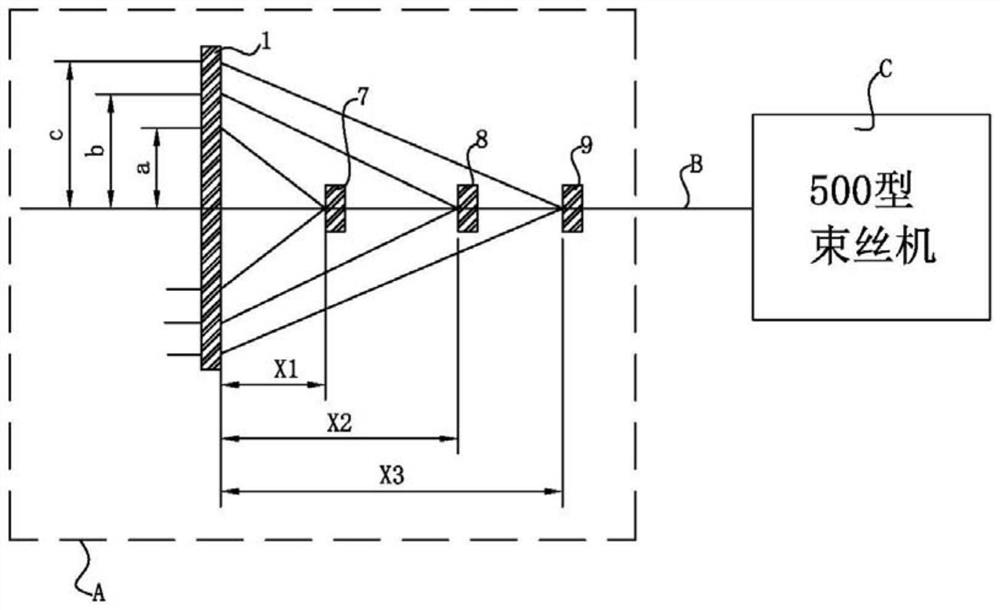

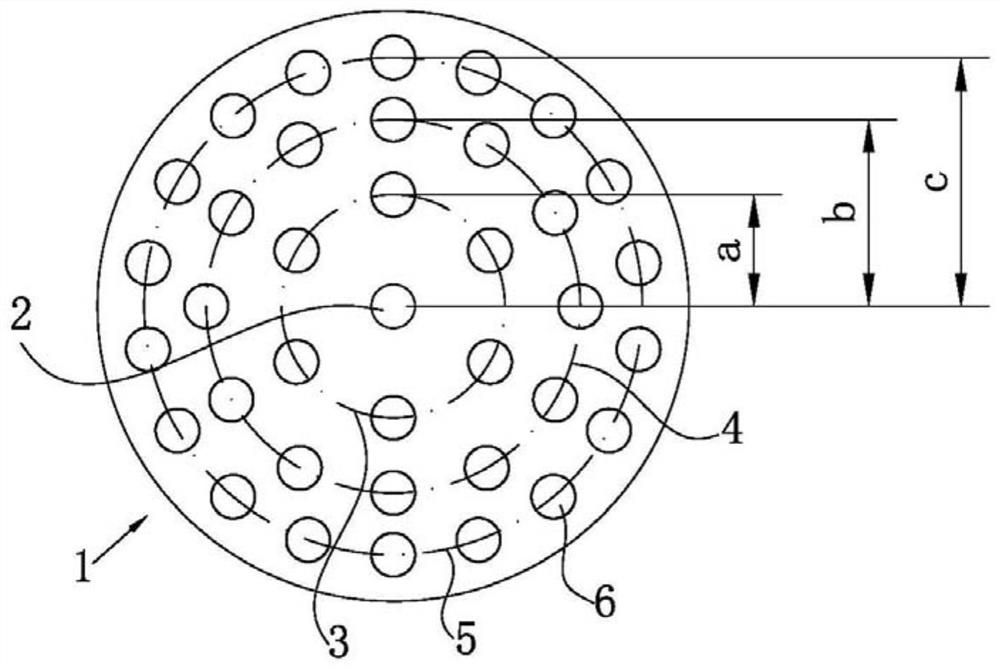

[0042] S1, a number of discrete conductors are aggregated through the branching polymerization mechanism A to form the unit B to be stranded, and the units to be stranded are arranged in the following manner: the first conductor layer formed by the first conductor; A second conductor layer formed by second conductors, the second conductors surround the first conductors, and the first conductor layer extends along the center direction of the second conductor layer;

[0043] In this embodiment, a third conductor and a fourth conductor layer are also included, the third conductor layer is formed by a plurality of third conductors located on the second circumference, and the fourth conductor layer is formed by a plurality of fourth conductors located on the third circumference. Conductors are formed, the third conductor layer surrounds the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com