Device and method for clamping irregular frame parts

A clamping device and irregular technology, applied in workpiece clamping devices, aircraft assembly, manufacturing tools, etc., can solve problems such as frame parts damage, achieve standardized management, and solve the effects of clamping inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

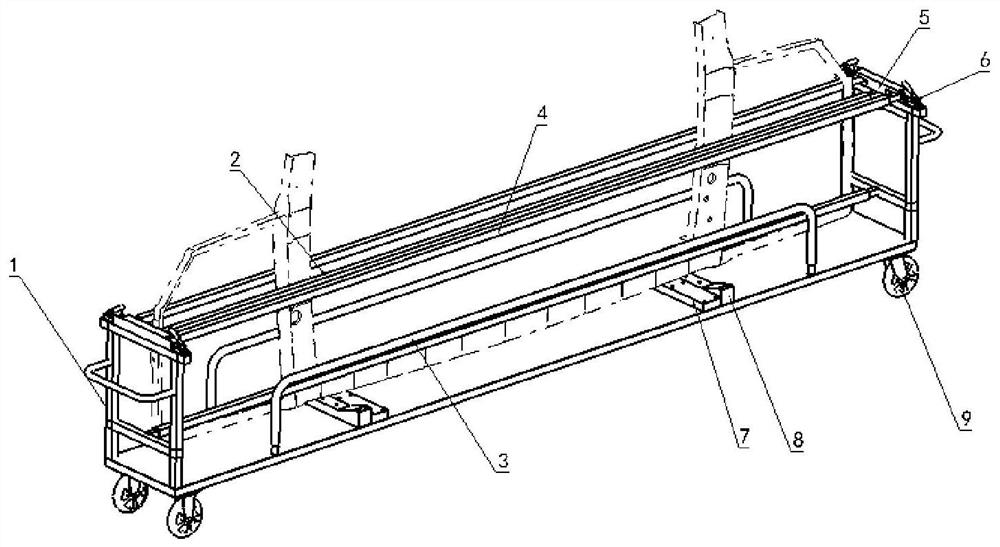

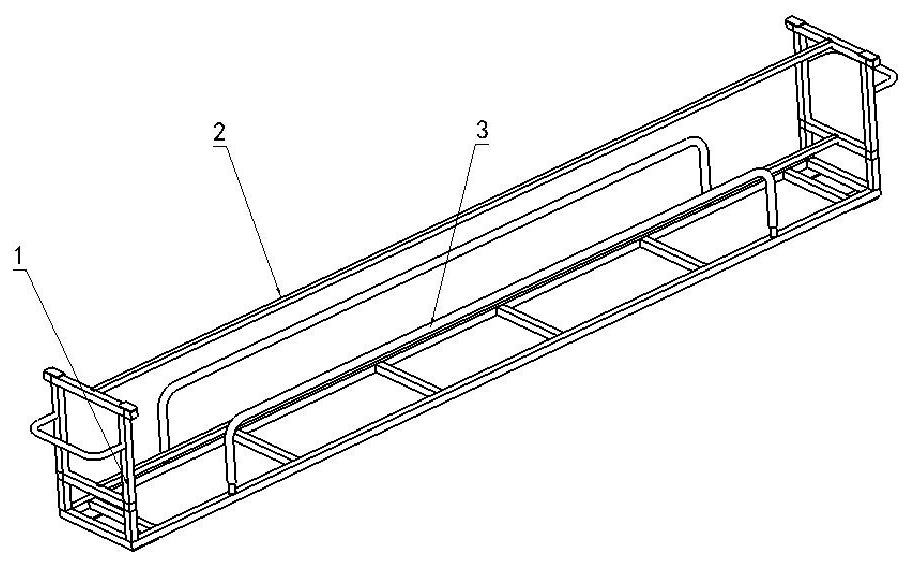

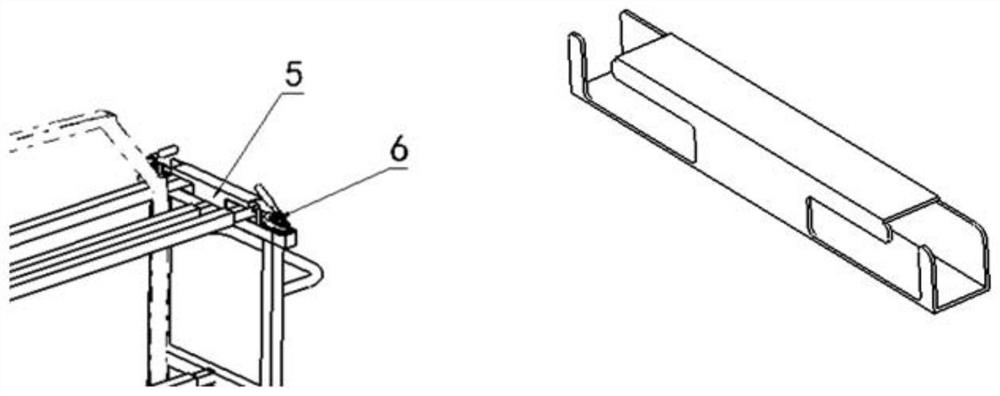

[0027] The specific implementation manners of the present invention will be further described in detail below. see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the positioning and clamping device for frame parts of the present invention includes a main frame 1, a middle partition 2, a blocking rail 3, a clamping rod 4, a special-shaped groove support 5, a pressing device 6, an inclined plane positioning block 7, and a V-shaped positioning block 8. Caster 9. The middle of the lower part of the main frame is the bottom plate and the frame, and there are supporting frames at both ends. The middle partition is connected with the upper beams of the supporting frames at the two ends of the main frame, and the outer part is wrapped with a soft protective cover, and the irregular frame parts are protected. Blocking and limiting, the blocking railing is connected with the middle frame of the main frame, and the outside is wrapped with a soft protective sleeve. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com