Robot servo torque control method based on speed control mode

A speed control and controller technology, which is applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of long design and development cycle and high cost, and achieve the effect of avoiding speeding and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

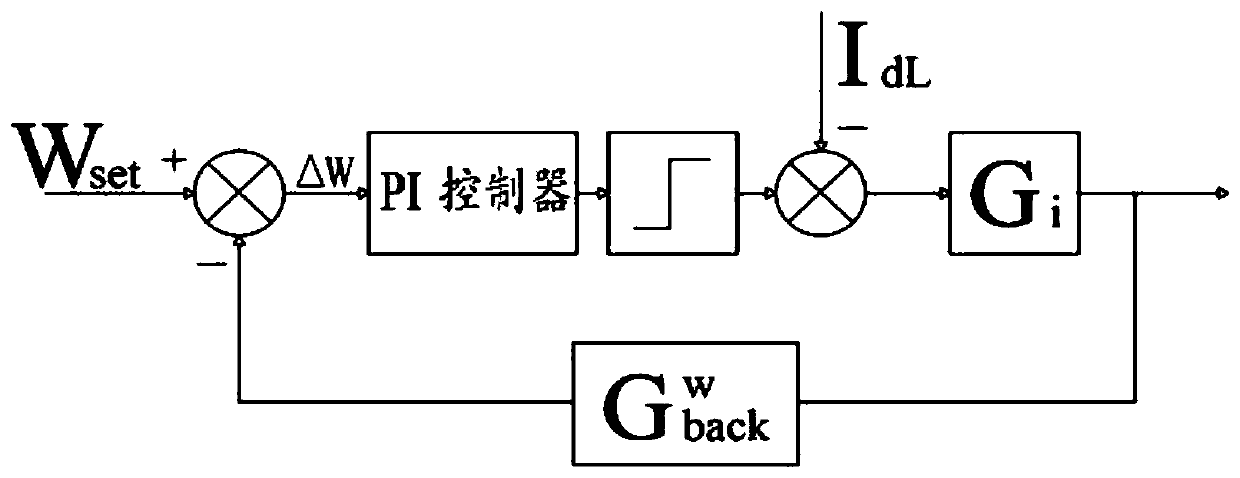

[0017] A robot servo torque control method based on speed control mode, including the speed control system loop, the improvement is: by adding a saturator with adjustable threshold after the PI controller of the speed control system loop, when the PI control When the control output of the controller reaches the upper and lower limit thresholds of the saturator, the speed control mode enters the constant torque control mode to realize the constant torque output of the servo motor.

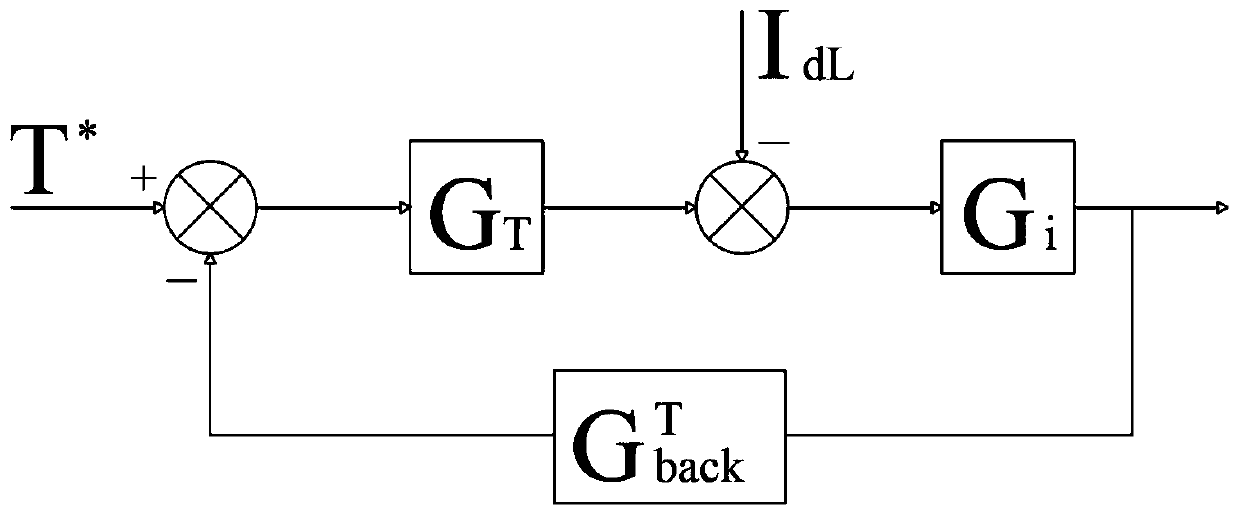

[0018] The servo motor torque control method in the prior art is to add a torque sensor in the control loop to achieve torque control, such as figure 1 As shown, the torque sensor is used to measure the torque output by the servo motor, and the negative feedback is used to compare with the torque given value, and the control error is input into the torque controller for calculation to produce the motor control quantity, so as to realize the error-free control of the servo system torque steady state ...

Embodiment 2

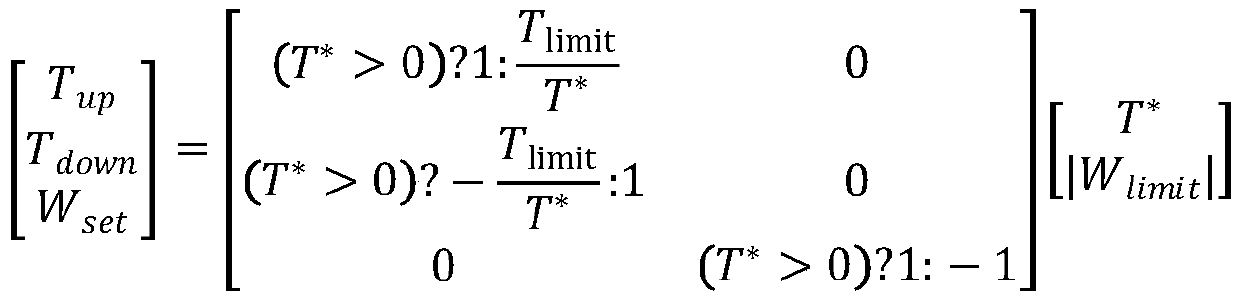

[0021] On the basis of Example 1, the threshold value of the saturator is set to change with the change of the expected given torque value, and the clockwise rotation of the servo motor is defined as positive, and the counterclockwise rotation is negative, and the speed given by the speed control system is The value and saturator threshold are set to satisfy the following relationship:

[0022]

[0023] where T up and T down are the upper and lower limit thresholds of the saturator, W set is the speed given value of the speed control system, T * and|W limit |respectively, the torque value and speed boundary limit value expected by the user, |W limit | is the maximum speed value to prevent the servo motor from flying, T limit It is the reverse control torque value that can realize the speed control in time when the servo motor speeds up, T limit Not limited by the saturator; the question mark is a conditional operator, which means that the value on both sides of the co...

Embodiment 3

[0027] On the basis of Example 2, when the user expects the servo system to output positive torque, the upper limit threshold T of the saturator in the speed control system up set to T * , the lower threshold T of the saturator down set to -T limit , speed given value W set set to |W limit |, the speed deviation ΔW input to the PI controller is positive, after the integral action of the PI controller, the output of the PI controller is continuously accumulated, and finally exceeds the upper limit threshold T of the saturator up , the speed control system controls the output size of the servo motor to be T * constant torque.

[0028] In this embodiment, when the user expects the servo system to output positive torque, according to the formula in Embodiment 2, it can be known that the upper limit threshold T of the saturator in the speed control system up Set to user desired given torque value T * , the saturator lower threshold T down Set as reverse control torque value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com