Fabricated shear wall cast-in-site segment small-spliced-mould casting construction system

A technology for shear walls and cast-in-place sections, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, walls, etc. Problems such as construction quality and assembly efficiency, to achieve the effect of ensuring the molding effect, improving the construction quality and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

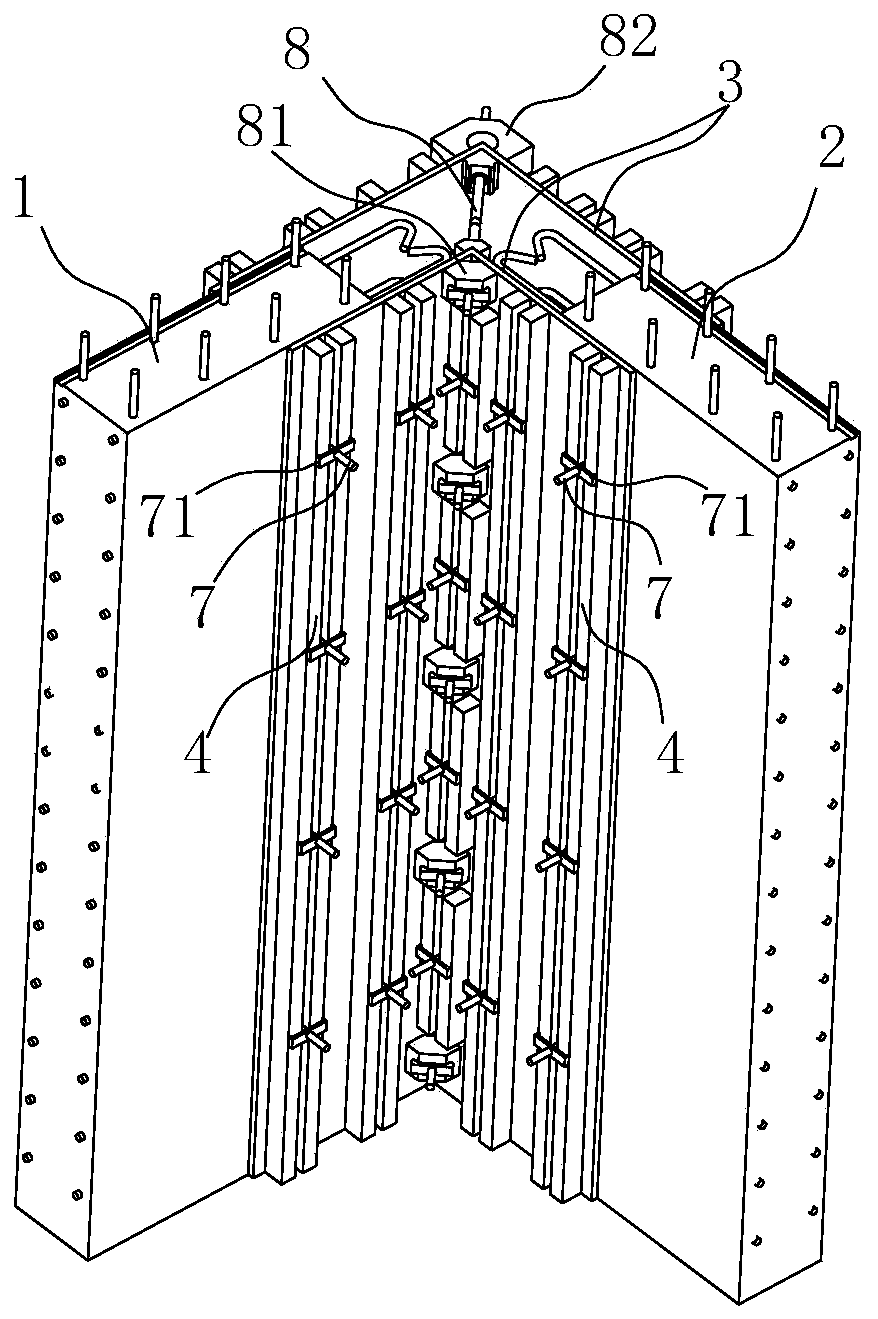

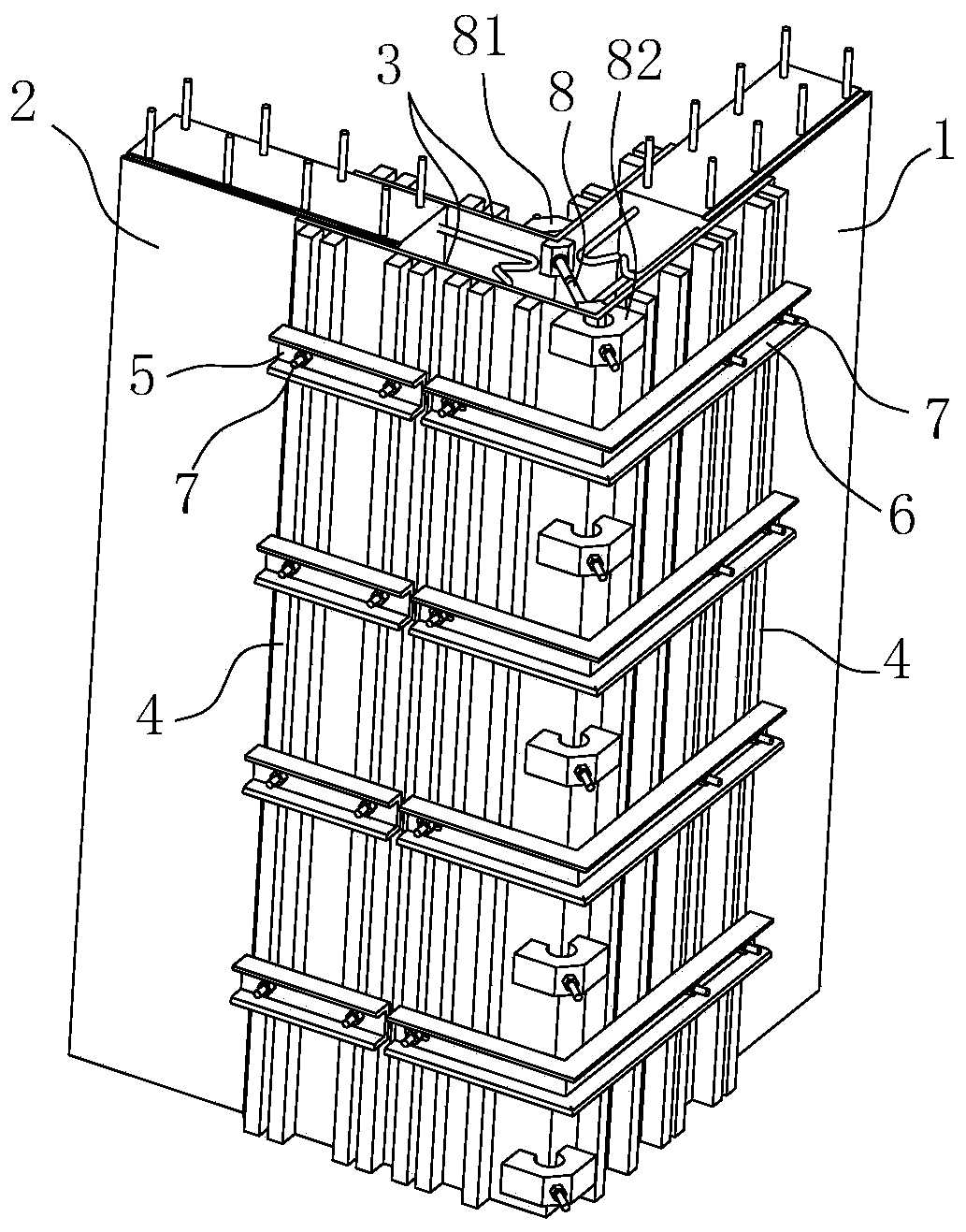

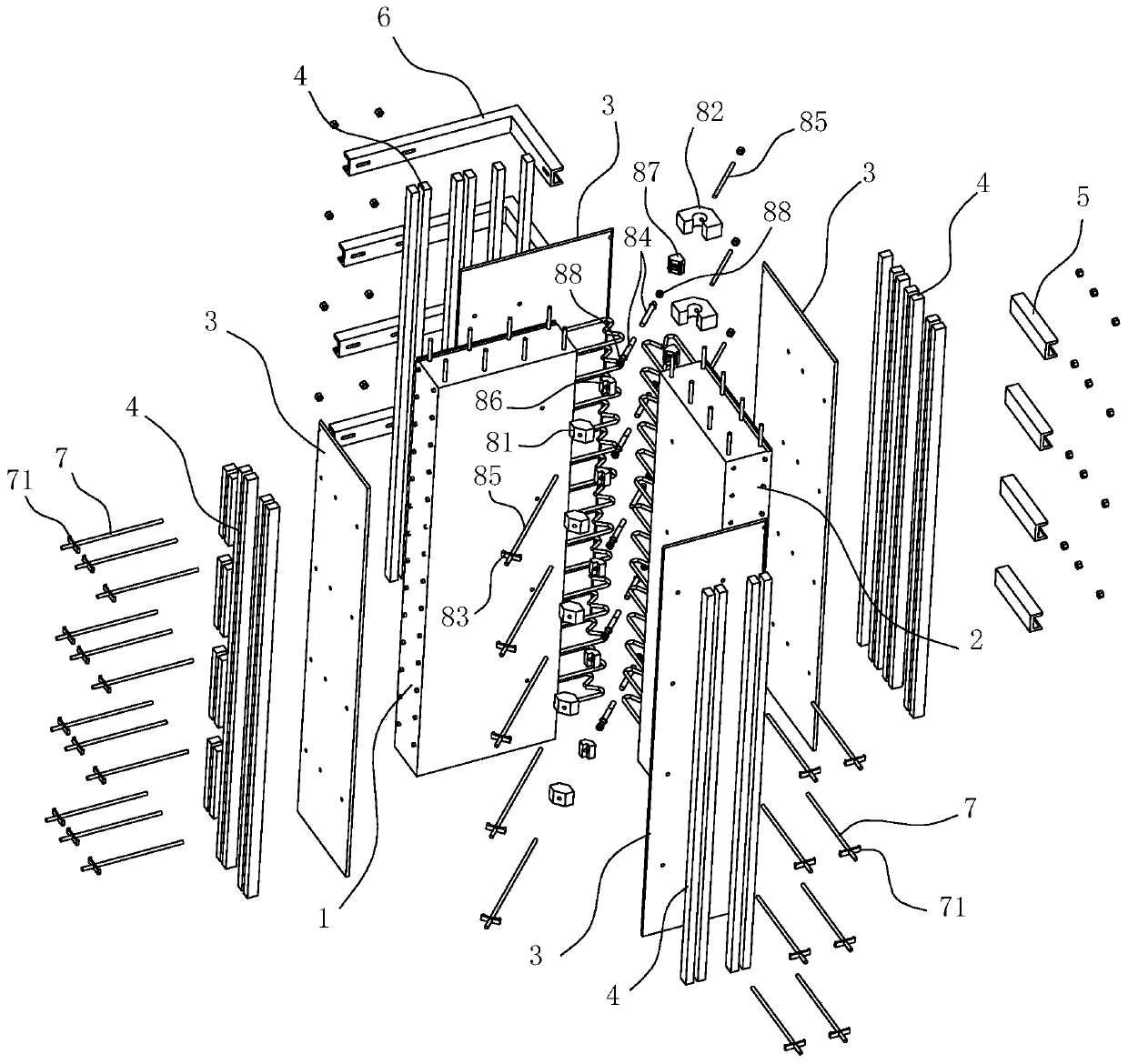

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. What needs special instructions is that the "inner" and "outer" in the present invention refer to the general appellations of both sides of the corner of the shear wall by those skilled in the art, that is, figure 1 The side shown is the inner side, figure 2 The side shown is the outer side.

[0022] Such as Figure 1-10 As shown, a prefabricated shear wall cast-in-place section small joint form pouring construction system includes prefabricated wall A1, prefabricated wall B2, formwork 3, wooden square 4, straight back corrugated 5, L-shaped back corrugated 6 and opposite Pull the screw 7, the prefabricated wall A1 and the prefabricated wall B2 are arranged vertically and spaced apart from each other, the templates 3 are attached to the inner and outer sides of the prefabricated wall A1 and the prefabricated wall B2 respectively, and the inside of the prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com