A fastening structure for cable binding

A technology for fastening structures and cables, applied in the direction of electrical components, etc., can solve the problems of bumps, can not be stably bundled, easy to unravel, etc., to achieve the effect of stabilizing the bundling of cables and avoiding the loss of the cable surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cables are usually twisted by several wires or groups of wires, similar to ropes, each group of wires is insulated from each other, and is often twisted around a center, and the entire outside is covered with a highly insulating coating. The cable has Internally energized, externally insulated.

[0032] When the cable is built or laid, its transportation is through the winding roller. However, in order to reduce the load, when transporting some short-length cables, most of them are directly wound up and tied with wire ropes. , due to the varicose stretching force of the cable and the smooth surface of itself, it cannot be bundled stably, and it is easy to fall apart due to bumps.

[0033] In view of the above problems, the present invention provides a fastening structure for cable bundling.

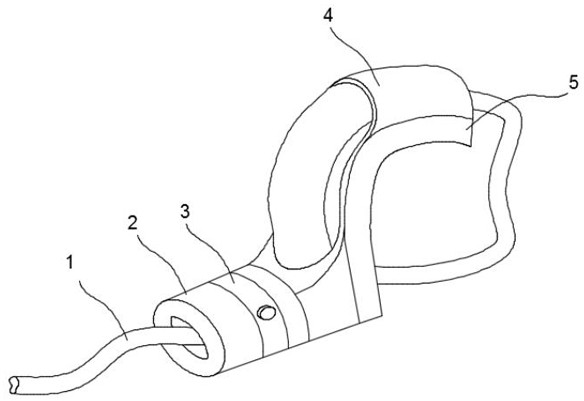

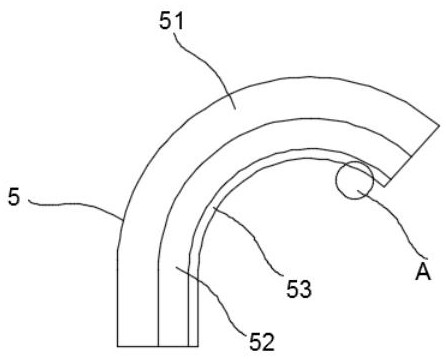

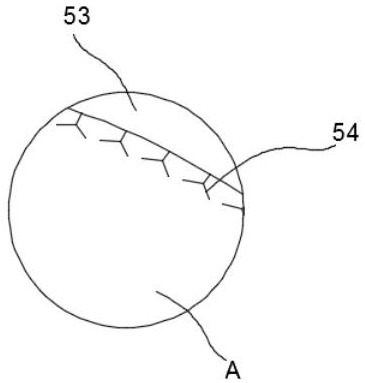

[0034] Specific as figure 1 As shown, a fastening structure for cable binding includes a limit case 4, and a through pipe 2 arranged in the limit case 4, and the structure also i...

Embodiment 2

[0044] The embodiment of the present invention is further limited on the basis of embodiment 1.

[0045] Such as Figure 5 As shown, the clamping ring 3 is provided with two symmetrically distributed clamping components 31 .

[0046] Optimally, the clamping assembly 31 is provided with a limit sleeve 35, and the inside of the limit sleeve 35 is movably interspersed with a penetration rod 33, and the penetration rod 33 and the limit sleeve 35 are fixed by a fixing pin 34, and the penetration rod 33 The upper matching fixing pin 34 is provided with a plurality of limiting holes distributed in an array, and an inner limiting plate 32 is fixed at the inner end of the insertion rod 33 .

[0047] Optimally, the inner limiting plate 32 is arc-shaped.

[0048] The working principle of the present invention is: the present invention is used for the fastening structure of cable binding, the fastening rope 1 binds the coiled cable on the inner limit buffer structure 5, and the buffer l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap