A kind of automobile drive shaft with anti-misoperation

A drive shaft and misoperation technology, applied in the direction of brakes, vehicle components, automatic starting devices, etc., can solve problems such as wrong recognition of accelerator and brake, aggravated accidents, accidents when starting or reversing, etc., and achieve low cost and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

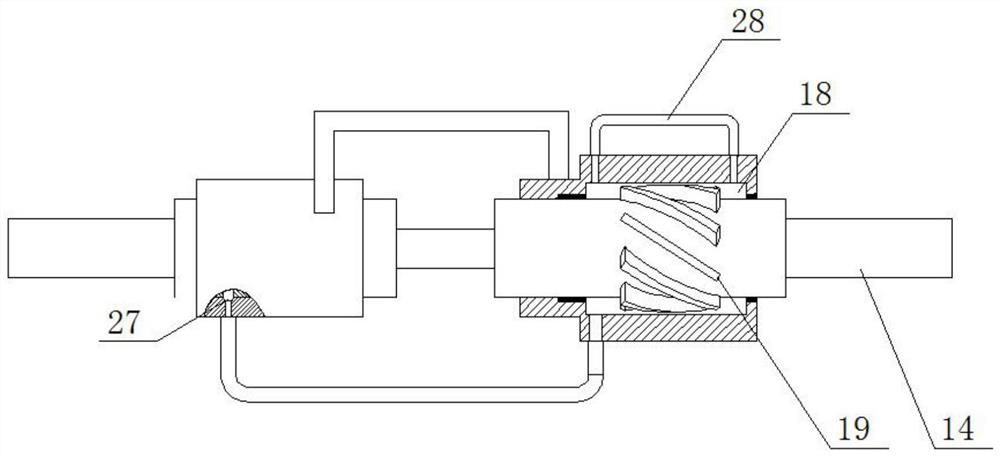

[0027] As a preferred embodiment of the present invention, a return spring 26 is provided on one side of the input triangular cylinder 25 .

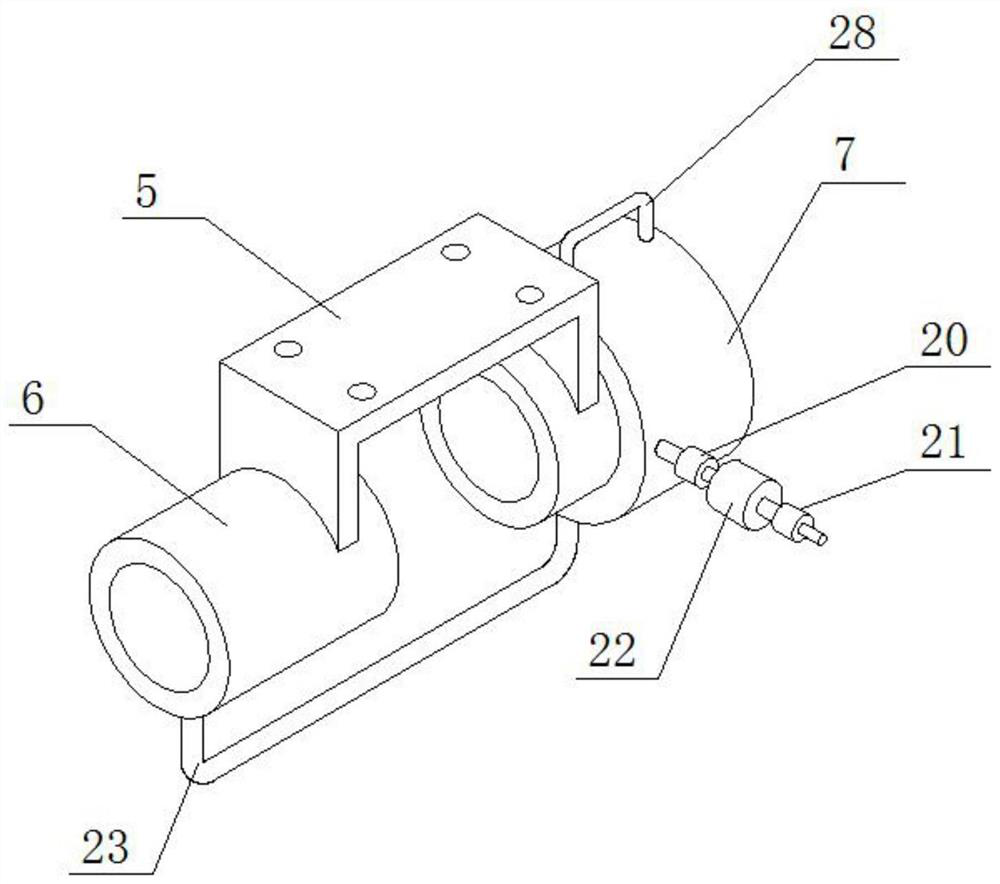

[0028] As a preferred embodiment of the present invention, an oil passage is evenly opened on the outer side of the output sliding sleeve 9, one end of the oil passage is connected to the oil cylinder 11 through a pipeline, and the inner wall of the output positioning sleeve 6 is opened with The annular groove 27 corresponding to the oil passage, the oil inlet pipe 23 communicates with the annular groove 27 .

[0029] As a preferred embodiment of the present invention, an oil return pipe 28 communicating with the oil chamber 18 is provided on the outer side of the input positioning sleeve 7 .

[0030] As a preferred embodiment of the present invention, the output triangular cylinder 24 and the input triangular cylinder 25 are provided with a slide plate 29, the slide plate 29 is provided with a rotary shaft, and a ball 30 is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com