Backlight module, display screen and terminal

A backlight module and light guide plate technology, which is applied in optics, nonlinear optics, printing devices, etc., can solve problems such as the camera area cannot be displayed, the terminal screen ratio is limited, and the terminal display effect is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

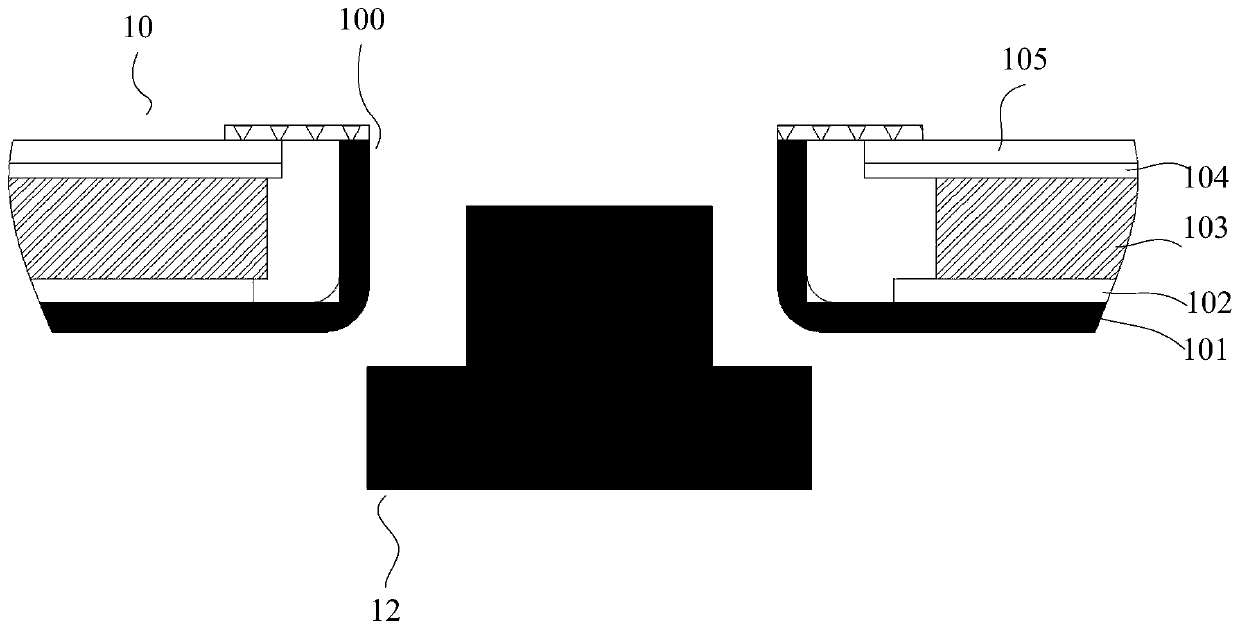

[0038] figure 1 It shows a schematic diagram of setting up an under-display camera. figure 1 Among them, the backlight module 10 is provided with a through hole 100, and the through hole 100 penetrates the outer frame 101 of the backlight module 10: the bottom wall of the outer frame 101 is provided with an upwardly protruding protrusion, and the through hole 100 penetrates through the outer frame 101 of the backlight module 10. The upper surface of the raised portion and the bottom of the outer frame 101 . The outer frame 101 also includes a side wall, and the side wall and the bottom wall form a semi-enclosed accommodation chamber, which accommodates the reflective film 102 of the backlight module 10, the light guide plate 103, and the diffusion sheet 104 sequentially from bottom to top. , Brightening film 105 . In this embodiment, the reflective film 102, the light guide plate 103, the diffusion sheet 104, and the brightness enhancement film 105 are all provided with open...

example 1

[0052] For some examples of this embodiment, see Figure 3a The schematic cross-sectional view of the backlight module shown: the backlight module 30a includes a main backlight module 31 and a sub-backlight module 32, the main backlight module includes an outer frame 311, and the bottom wall of the outer frame 311 protrudes upwards to form a raised portion, the convex There is a through hole 300 in the rising part that runs through the upper surface of the raised part and the lower surface of the bottom wall of the outer frame. The main backlight module 31 also includes a reflective film, a main LED light source, a main light plate, and a diffusion sheet arranged on the bottom wall of the outer frame. and glossy film. The main backlight module 31 is a side-lit backlight module, so the LED chip in the main LED light source has a light-emitting side, and its light-emitting side is just facing the light-incoming side of the main light plate. In this embodiment, the top of the ra...

example 2

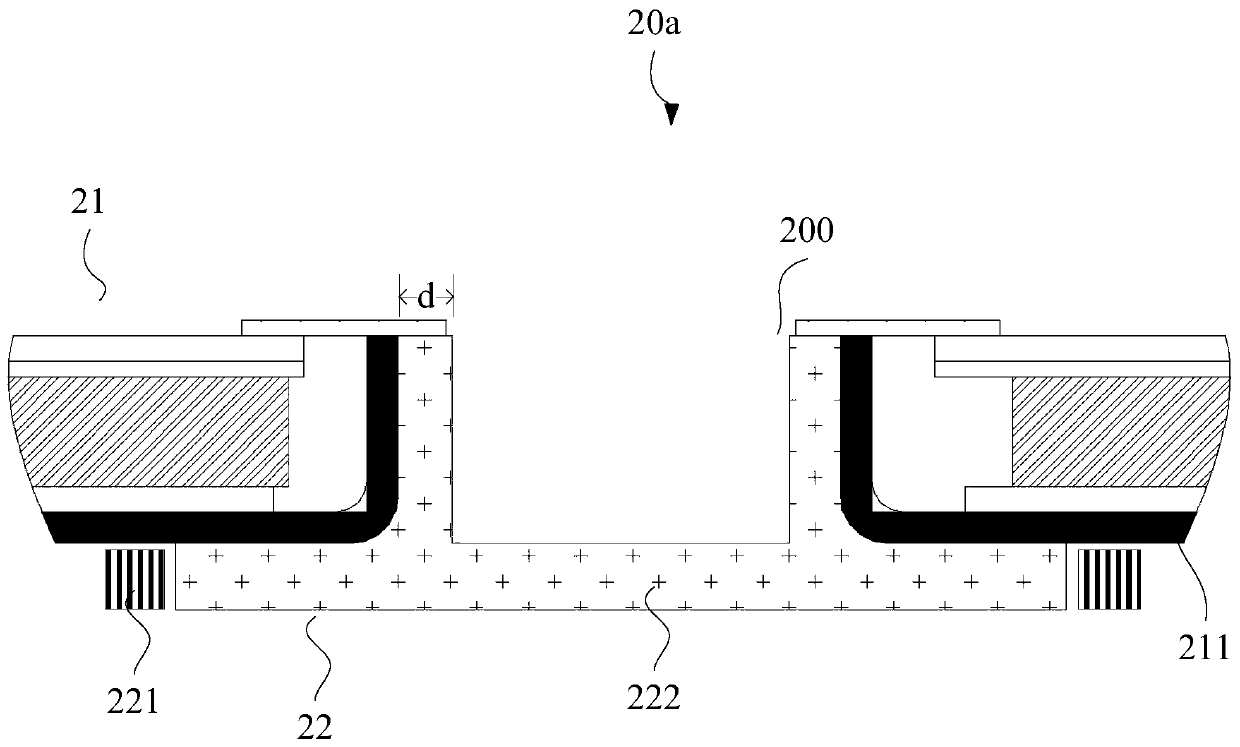

[0063] please continue to combine Figure 2a , in this example, the light exit part of the auxiliary backlight module 22 protrudes into the through hole 200, and the upper surface is recessed downwards to form a downwardly recessed groove, which is referred to as a "lower groove" here. . It should be noted that although the light exit portion of the secondary light guide plate 222 is recessed downward through the lower groove, the depression of the light exit portion does not reach the bottom surface of the secondary light guide plate 222, that is, the lower groove is not a groove that runs through the secondary light guide plate 222 . In some examples of this embodiment, the thickness of the groove bottom of the lower groove is equal to the thickness of the light entrance part of the sub-light guide plate 222, for example Figure 2a shown.

[0064] In some examples of this embodiment, the top of the side wall of the lower groove is flush with the top of the raised portion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com