Automatic generation method for die presser main rib line

A technology of automatic generation and presser, which is applied in the direction of geometric CAD, can solve the problems of not using mathematical models and the complexity of the environment, and achieve the goal of improving design efficiency and rationality, improving design efficiency, improving design efficiency and design accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

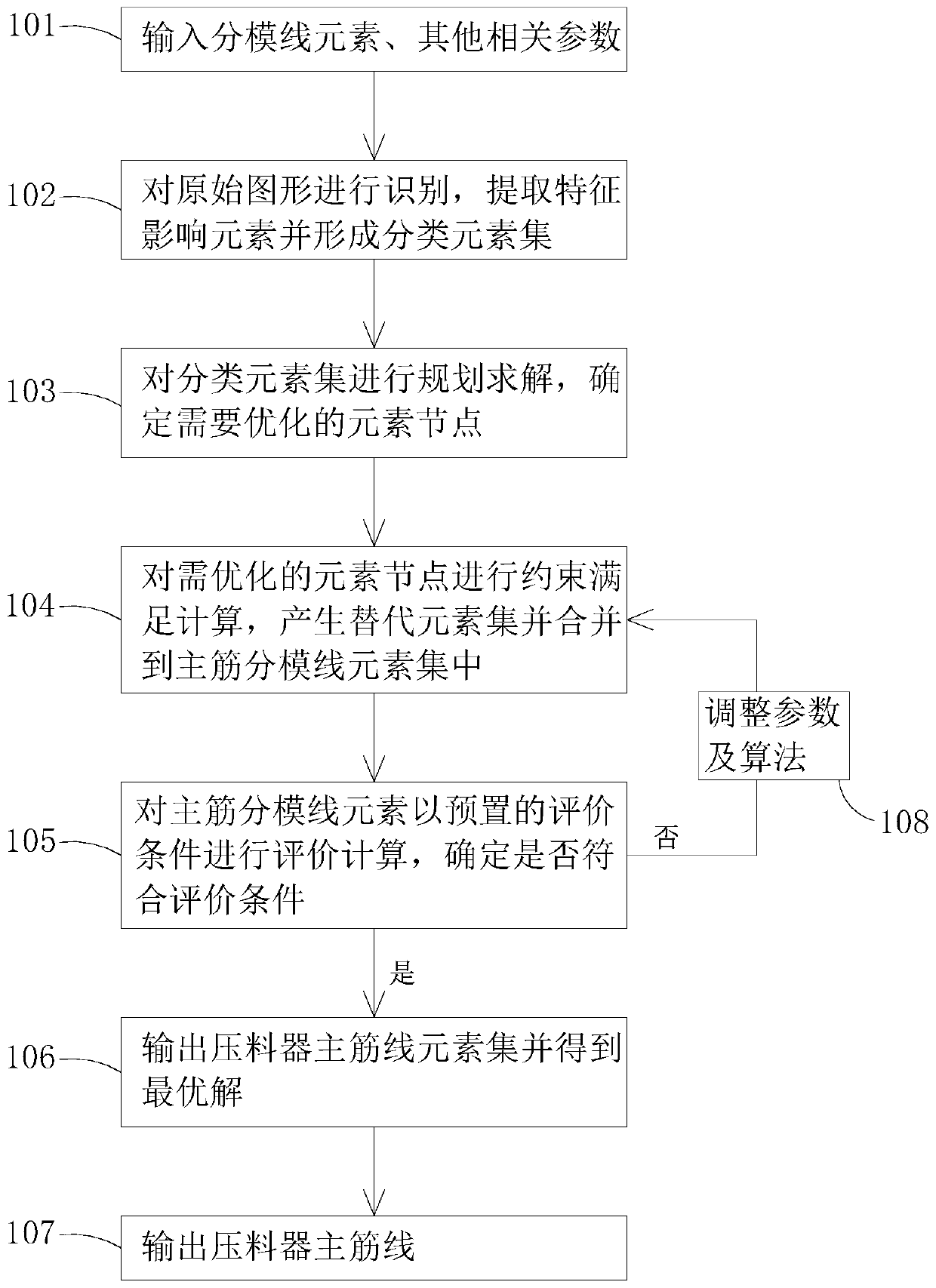

[0028] Below in conjunction with accompanying drawing, invention is described in further detail.

[0029] figure 1 Schematically shows a method for automatically generating main ribs of a mold presser according to an embodiment of the present invention.

[0030] refer to figure 1 , a method for automatically generating main ribs of a mold presser, is characterized in that, comprising the steps of:

[0031] Step 101: input parting line elements and other relevant parameters;

[0032] The input parting line elements and other related parameters include parting line (Punch_Divide_Curve), working surface (SW), offset leather surface (S_Offset) and working area set (Area_Set), etc. Parting line elements refer to the elements obtained by extracting and calculating process features according to process-related rules and parameters.

[0033] Step 102: Recognize the original graphic, extract feature-influencing elements and form a classification element set;

[0034] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com