Spreaders for efficient tank loading and unloading

A high-efficiency, tank-body technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of long time-consuming and incapable of automatic loading and unloading of ceramic wine cans, achieve efficient automatic loading and unloading, improve stability, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

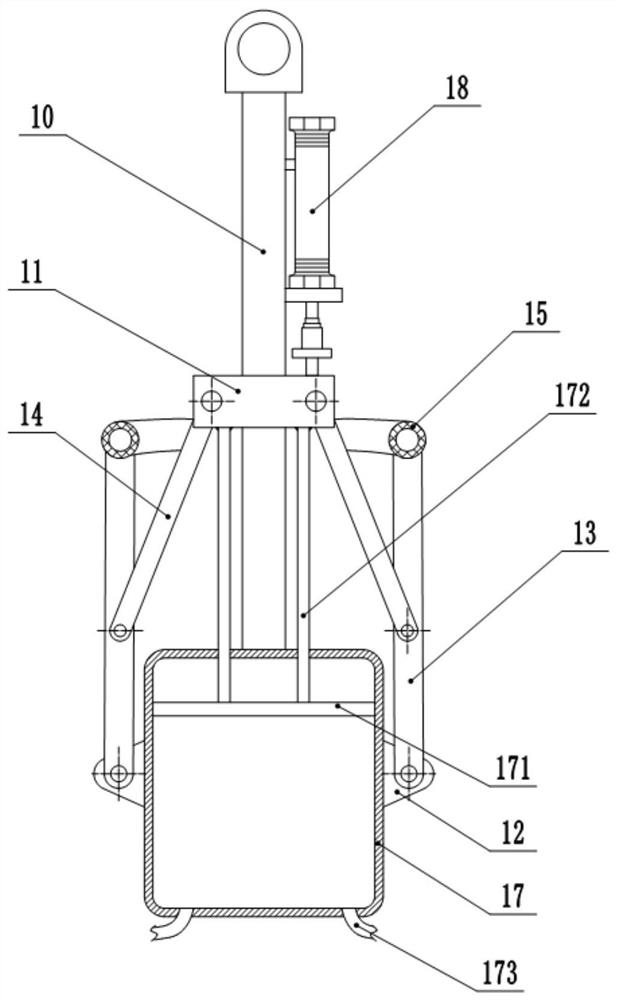

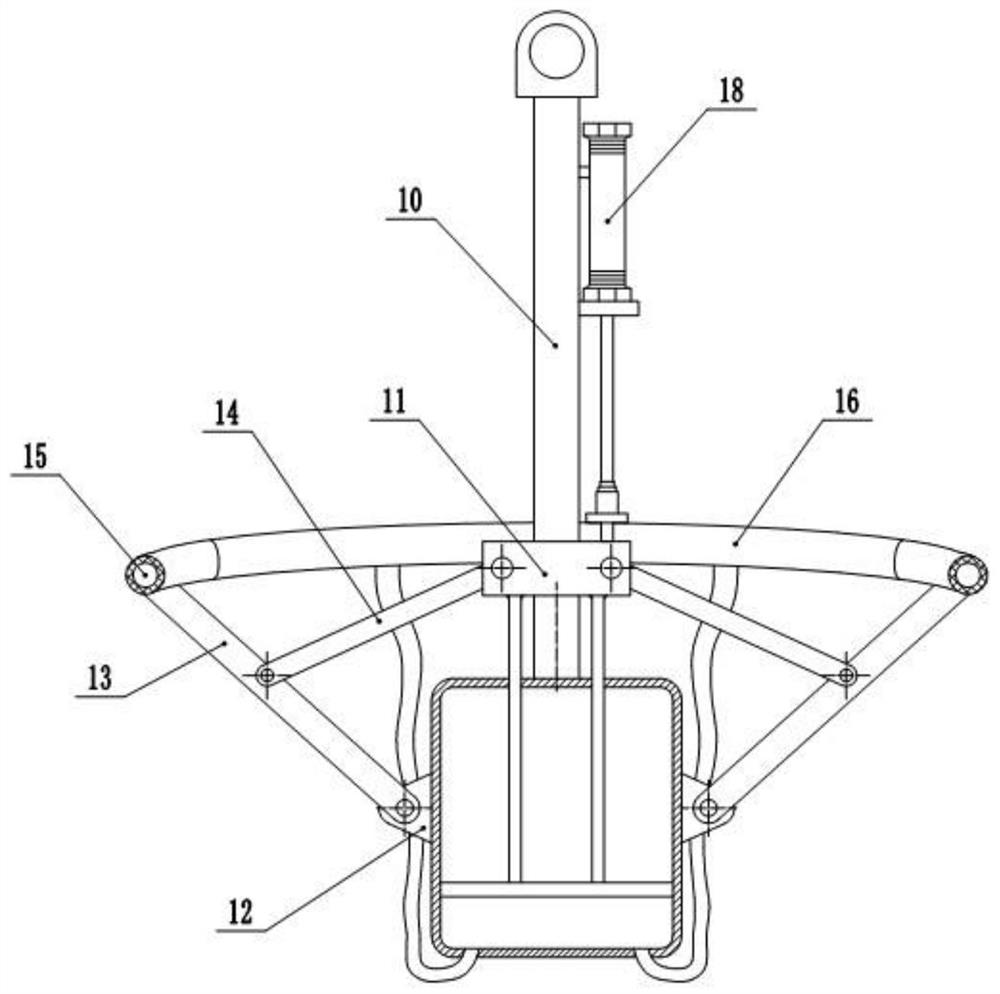

[0033] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

[0034] The lifting tool for efficiently loading and unloading tanks includes a vertical shaft 10, a sliding seat 11 and a cylinder body 17 with a closed bottom. A pull ring is fixed on the top of the vertical shaft 10, and the hook on the electric hoist can be directly worn on the pull ring. The sliding seat 11 is slidably connected on the vertical shaft 10, and the cylinder body 17 is fixed on the bottom of the vertical shaft 10, and a plurality of connection seats 12 are fixed on the side wall of the cylinder body 17, and the connection seats 12 are evenly distributed along the circumference of the cylinder body 17, A support rod 13 is hinged on the connecting seat 12, a pull rod 14 is hinged between the support rod 13 and the sliding seat 11, and a plurality of mounting grooves are arranged on the outer circumference of the sliding seat 11, and the end of the pull rod 14 away from the support rod ...

Embodiment 2

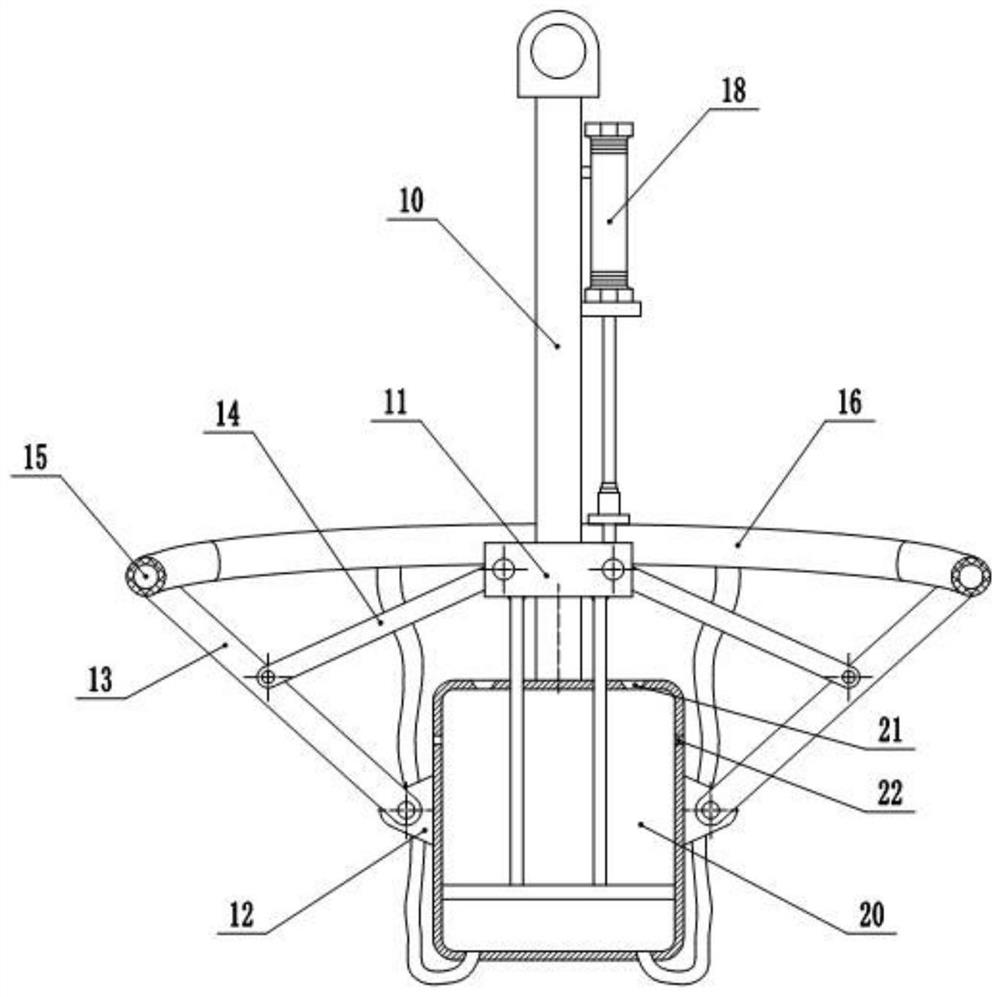

[0039] Embodiment 2 is basically as attached image 3 Shown:

[0040] The difference from Embodiment 1 is that the top of the cylinder body 17 is closed, and the piston 171 separates the cylinder body 17 into a closed upper cavity 20 and a lower cavity, and the top of the cylinder body 17 is provided with a positioning hole for the connecting rod 172 to slide. The top of the body 17 is provided with a plurality of air outlet holes 21 uniformly distributed along the vertical axis 10 circumferentially. The upper part is provided with the air inlet 22 that communicates with the upper chamber 20, and the air inlet 22 is provided with an air intake check valve. When the volume of the upper chamber 20 increases, the air pressure in the upper chamber 20 decreases, and the air intake When the one-way valve is opened, outside air enters the upper chamber 20, and when the volume in the upper chamber 20 decreases, the air pressure in the upper chamber 20 increases, the air outlet check ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap