An aluminum formwork milling groove fixing device

A technology for fixing devices and aluminum templates, applied in positioning devices, feeding devices, clamping, etc., can solve problems such as poor splicing of aluminum templates, inaccurate cutting, and danger of aluminum templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

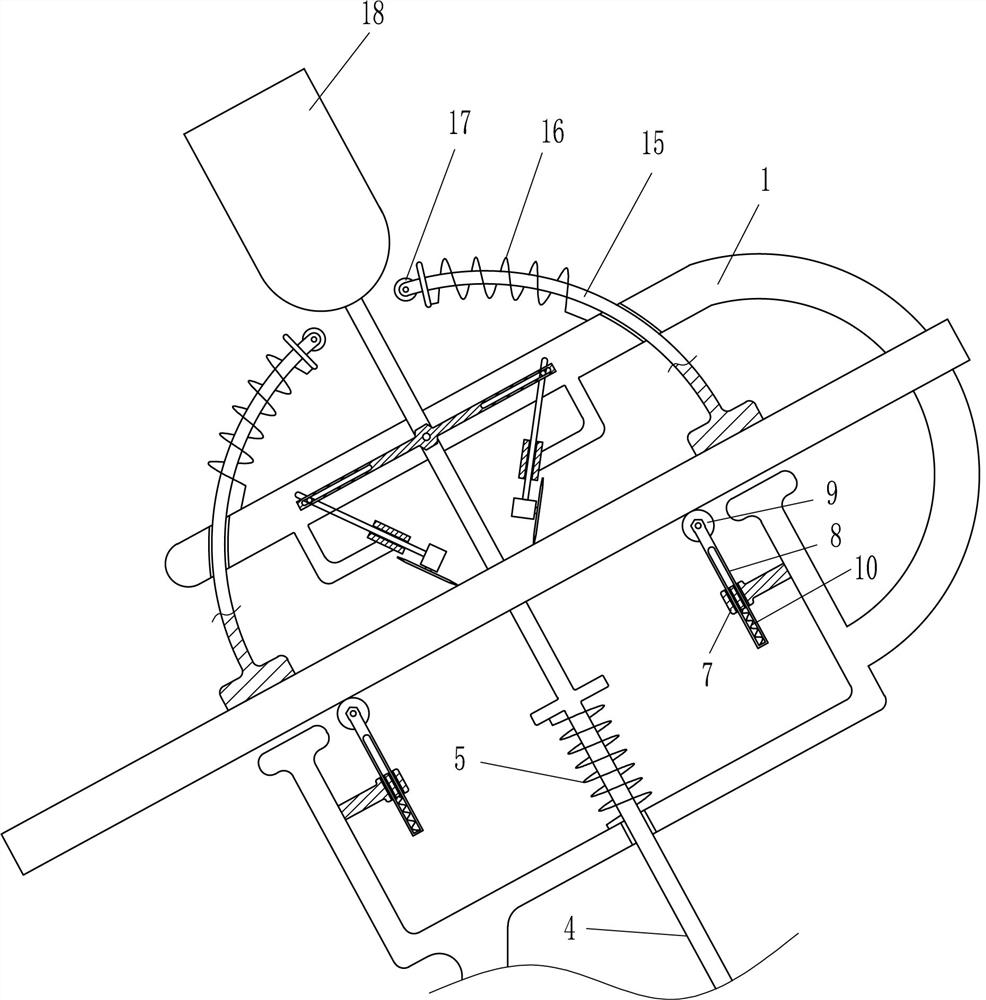

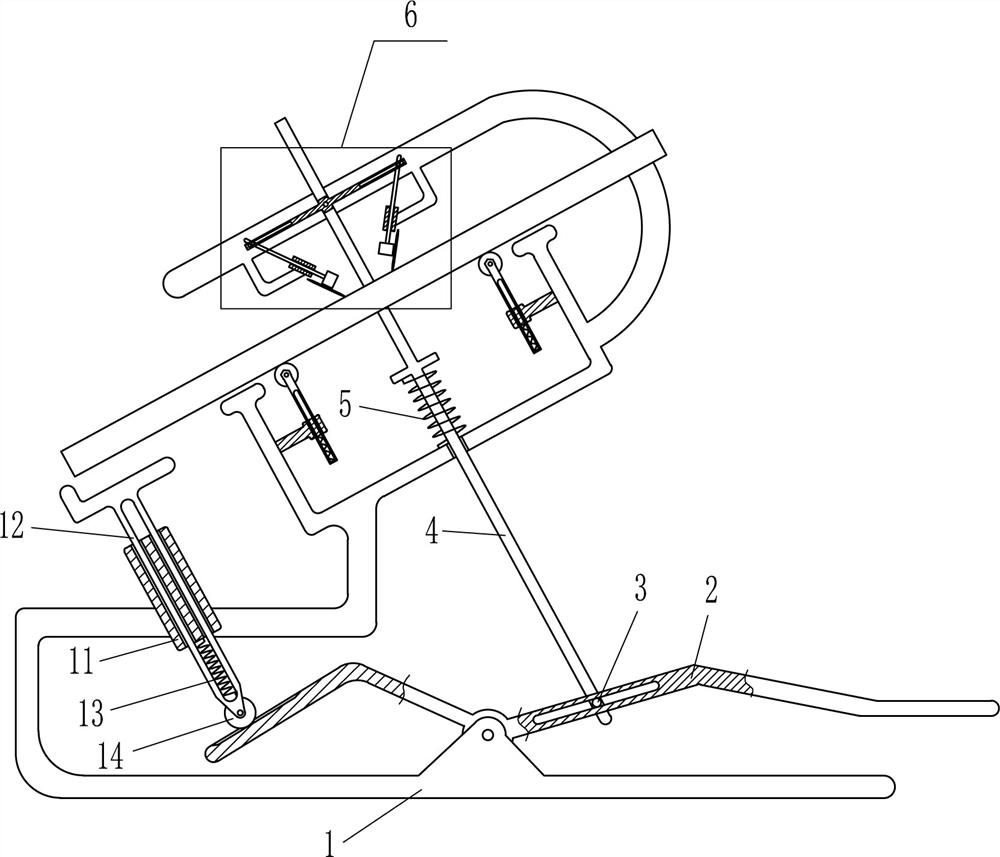

[0018] Aluminum template milling tank fixing device, such as Figure 1-3 As shown, including a bracket 1, the swing lever 2, the first pin lever 3, the first slider 4, the first spring 5, the cutting device 6, the second slider 7, the third slider 8, the first roller 9, The second spring 10, the stent 1 is rotated and connected to the swing rod 2, and the swing lever 2 is slidably connected to the first pin lever 3, the central sliding connection of the bracket 1 has a first slider 4, the bottom of the first slider 4. Attached to the first pin lever 3, the first slider 4 is connected to the stent 1 having a first spring 5, and the upper portion of the stent 1 is provided with a cutting device 6, and the bracket 1 is symmetrically provided with the second slider 7, the second slider 7 The third sliding rod 8 has a third slider 8, and the upper rotation of the third slider 8 has a first roller 9, and the third slider 8 is connected between the second sliding sleeve 7, and the second ...

Embodiment 2

[0023] On the basis of Example 1, if figure 1 As shown, there is also a third slider 11, the fourth slider 12, the third spring 13 and the second roller 14, and the left fixed connection of the bracket 1 has the third slider 11, the third slider 11 sliding The third spring 13 is connected between the third spring 13, and the bottom rotation of the fourth slider 12 is connected between the fourth slider 12 and the third slide 11, and the second roller 14 is connected. 14, the second roller 14 and the swing The rod 2 is in contact.

[0024] When used, the swing rod 2 is swing downward, and the second roller 14 is moved upward. The fourth slider 12 moves upward to the third spring 13, and the fourth slider 12 is moved upward. A function of supporting the aluminum template to prevent the aluminum template from sliding to the left to slide to the left, and after use, the fourth slider 12 is reset due to the elasticity of the third spring 13.

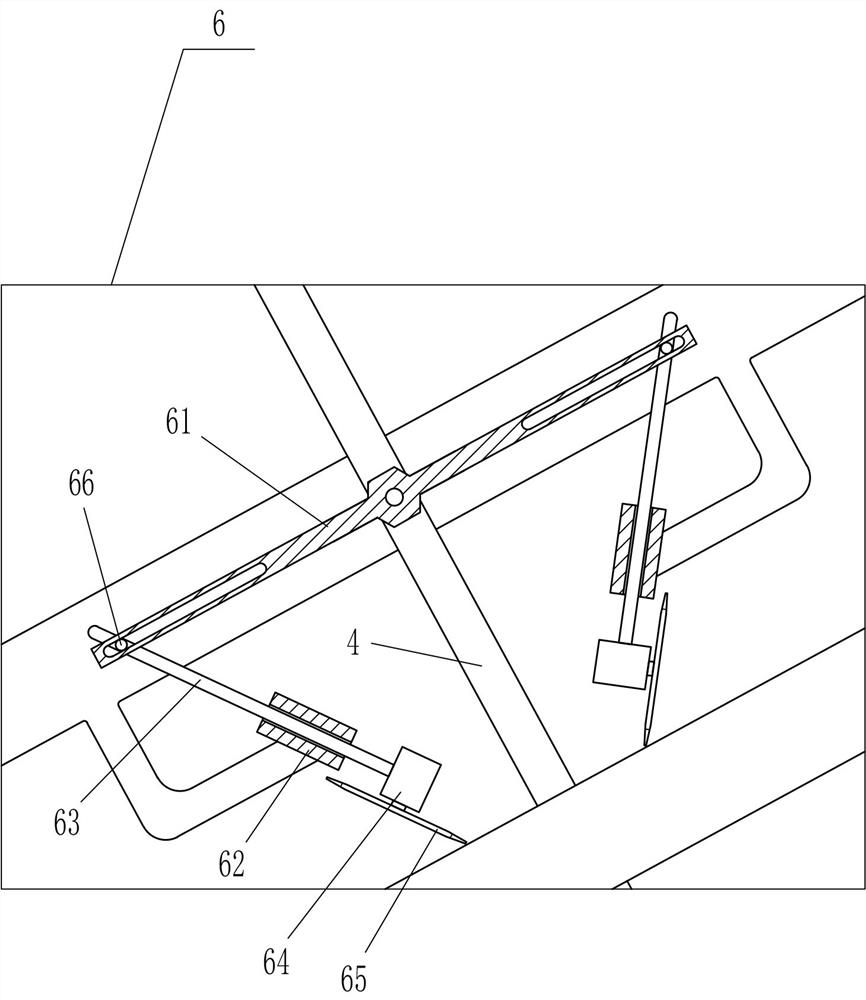

[0025] like image 3 As shown, there is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com