Steel cable monitoring device and steel cable monitoring method

A monitoring device and steel cable technology, applied in the directions of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of large labor force and time, and achieve the effect of correct state monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] (principle of invention)

[0031] Before describing the embodiments of the present invention, the basic principle of the present invention (principle of the invention) will be described.

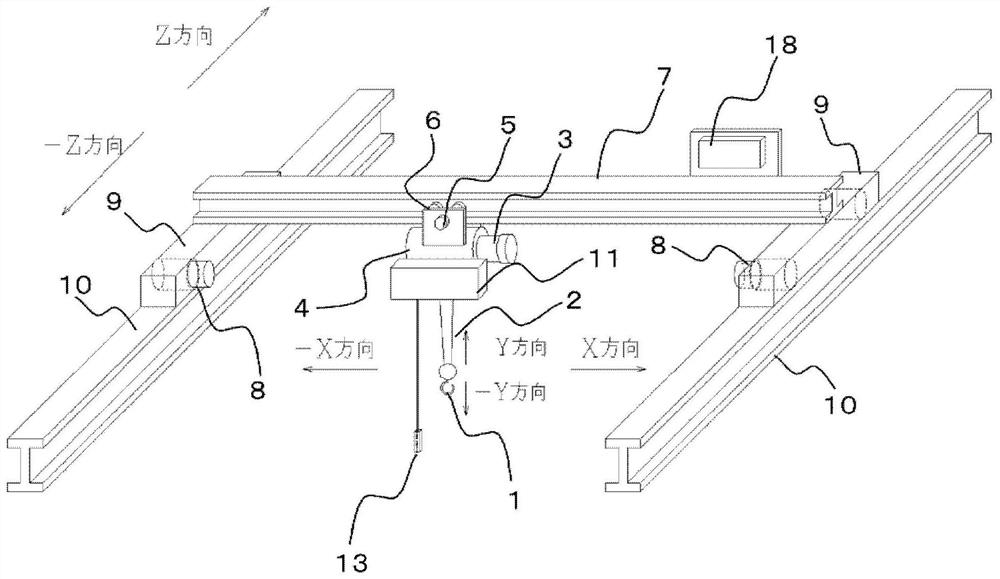

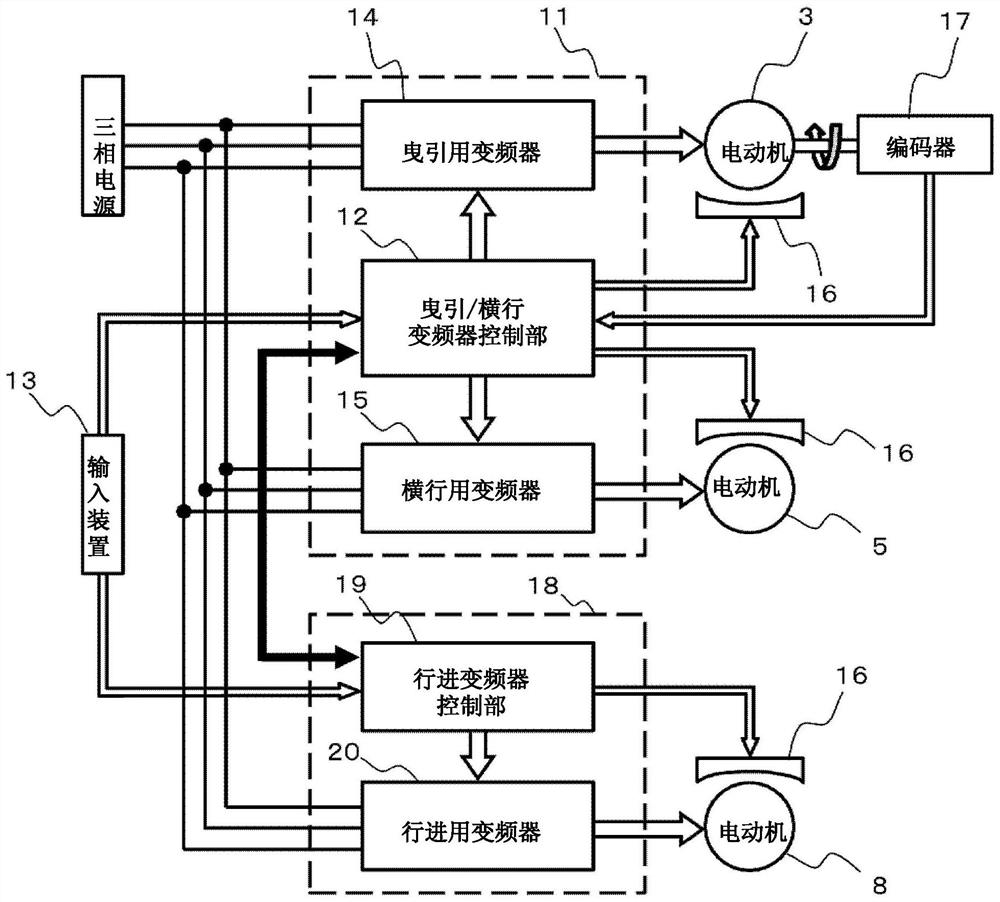

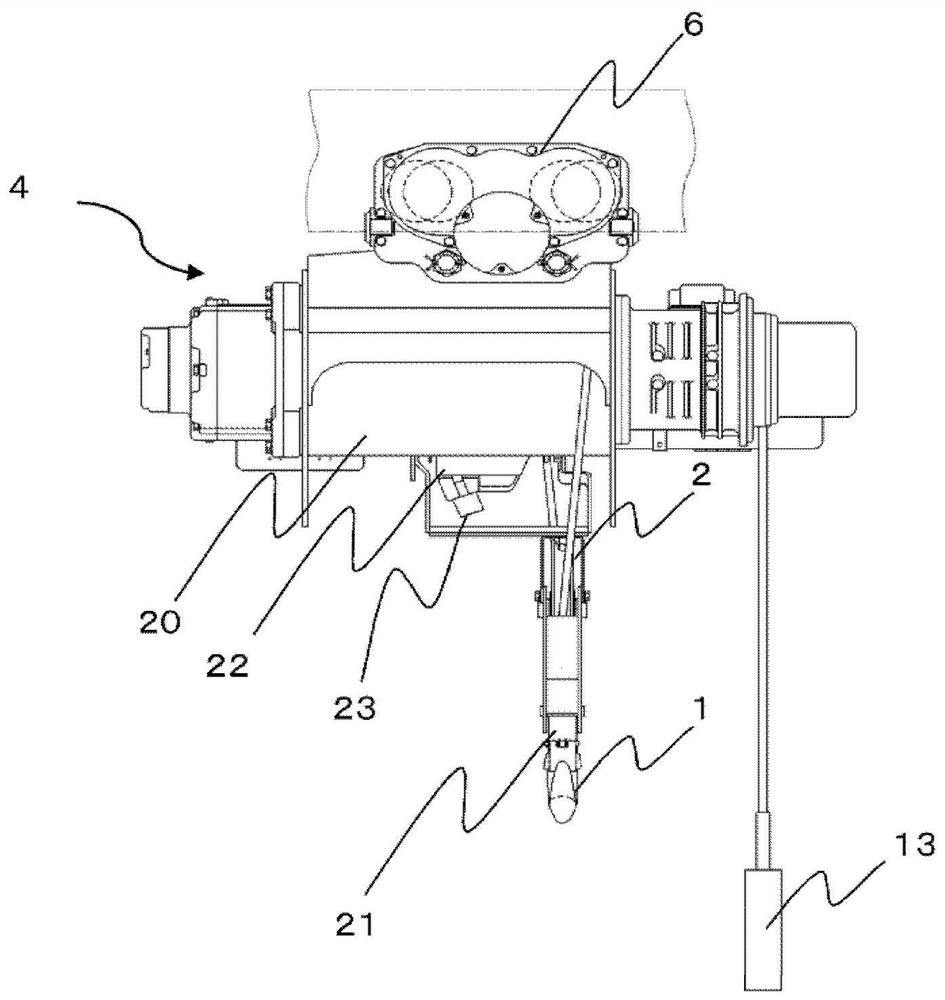

[0032] First of all, a crane is a mechanical device for the purpose of suspending heavy objects by power and transporting (moving) them horizontally. Therefore, a crane generally includes: a traction device for moving (transporting) the hoisting weight in the vertical direction (direction of gravity) by winding up and down the steel cable; and a horizontal movement device for moving the hoisting weight in the horizontal direction. . Here, the movement in the horizontal direction is a general term for the movement in the horizontal direction of the wire rope or the hoist. The device for horizontal movement includes a device that performs traverse and travel in bridge cranes or the like, or a device that performs rotation in slewing cranes.

[0033] Since the wire rope is damaged (ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com