Patents

Literature

48results about How to "Automatic recording" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

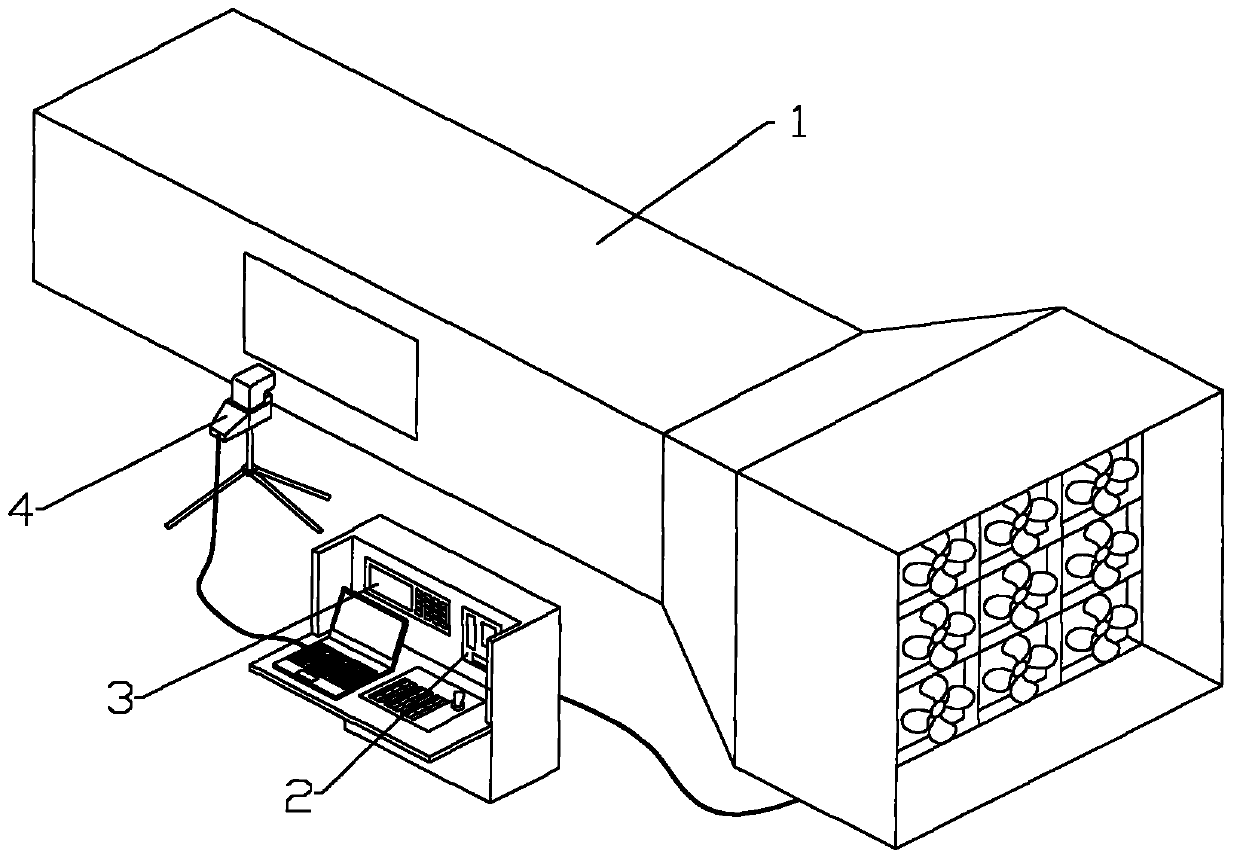

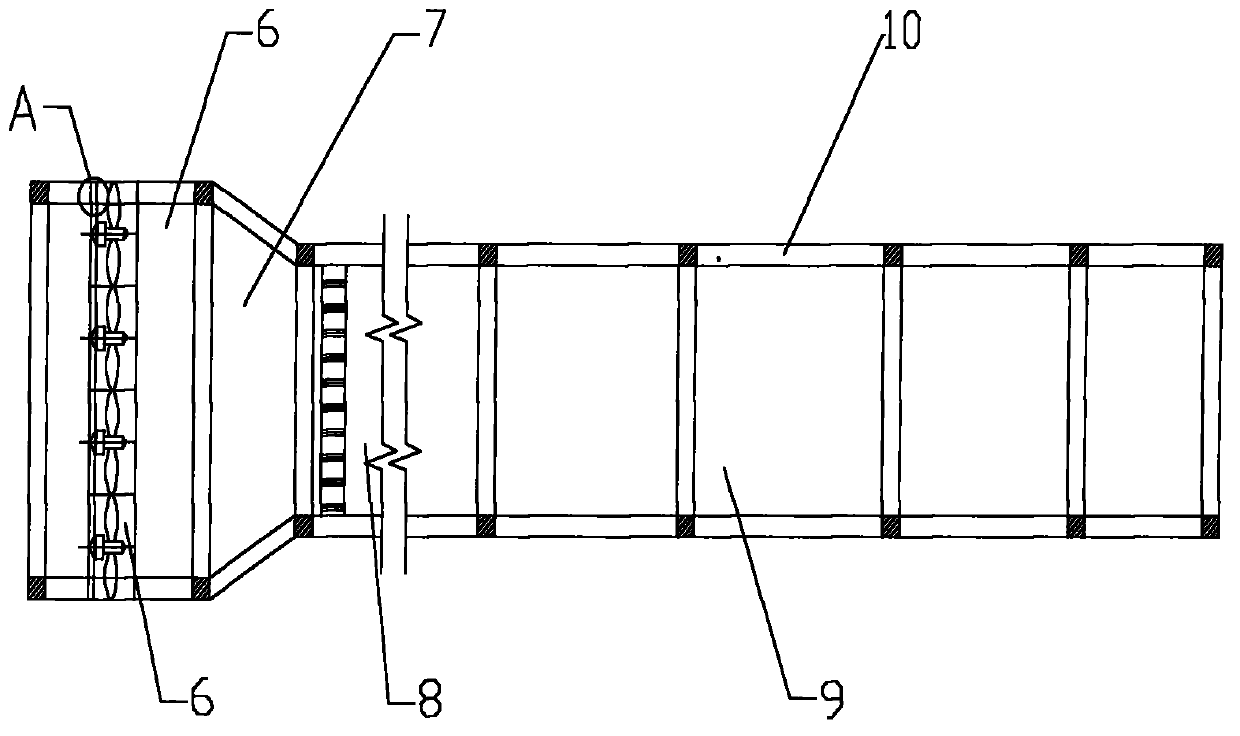

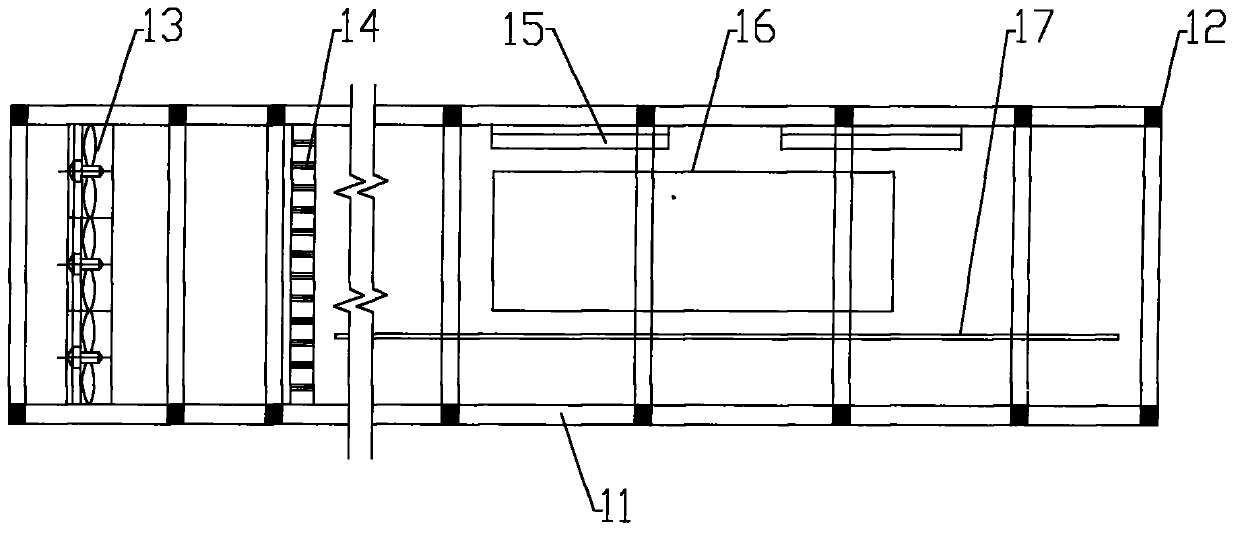

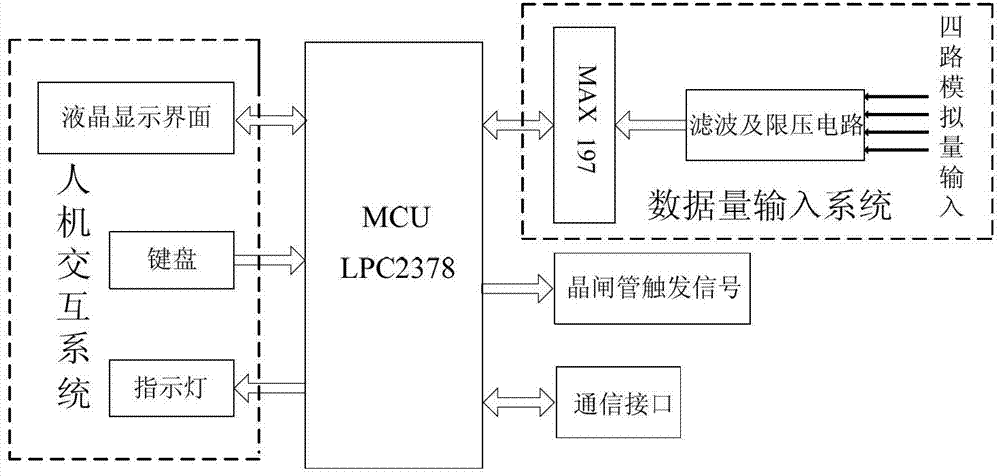

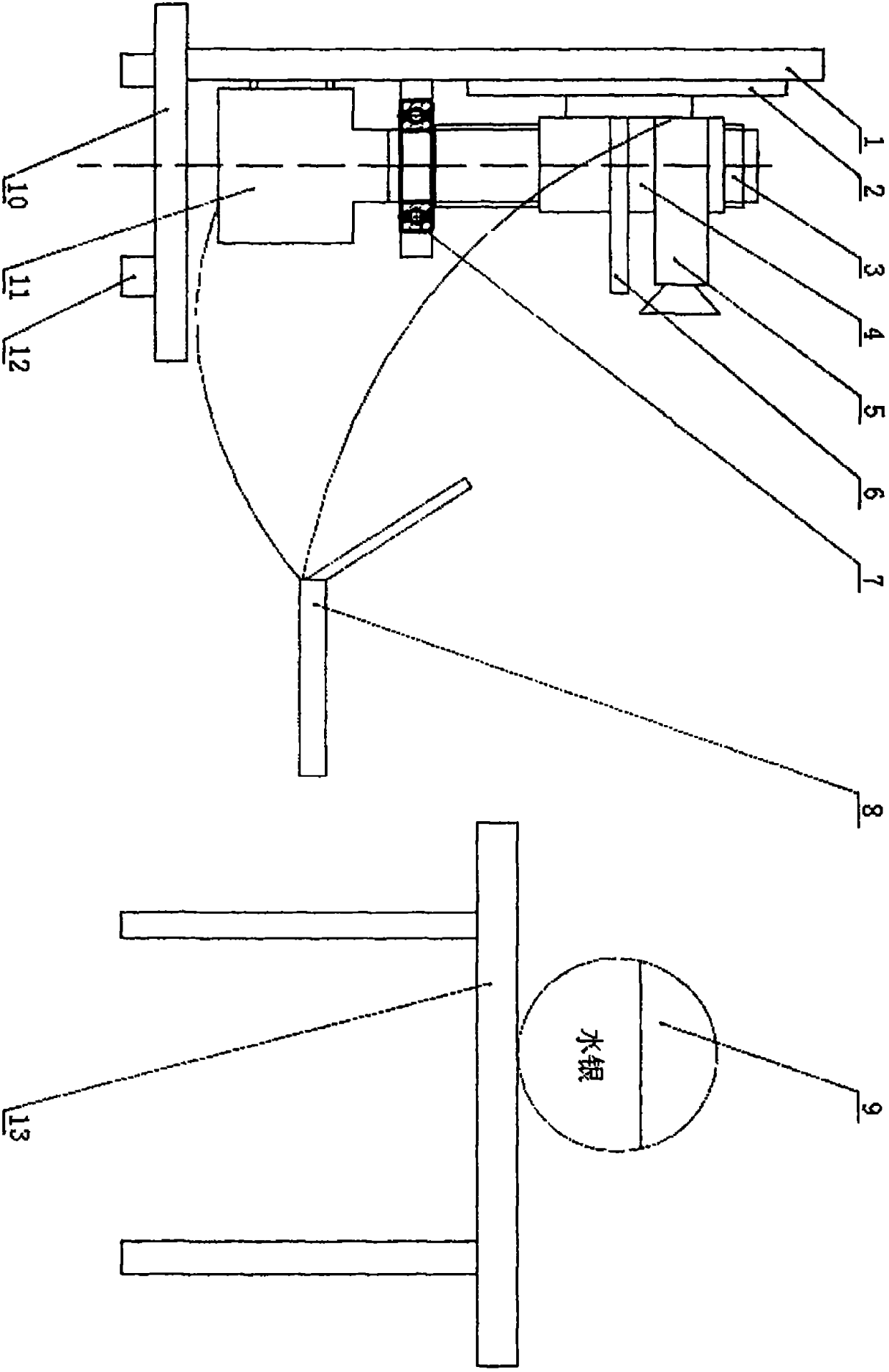

Digitized wheat lodging-resistant experiment wind tunnel

The invention provides a digitized wheat lodging-resistant experiment wind tunnel. The wind tunnel comprises four units of a wind tunnel body unit, a wind speed control unit, a wind speed determination unit, and an image automatic acquisition unit. The structural characteristics are that the wind tunnel body is integrally installed on a steel frame welded by rectangular steel tubes, an upper wall and side walls are formed by bending color plates which are filled with foam materials inside, two ends of the tunnel body and a front part and a rear part of a contraction section are provided with n-shaped steel frames, a lower layer of a baseplate is a wood board, and an upper layer is a galvanized iron sheet. Axial flow fans are installed on a frame which is welded by angle iron through screws, the fans being divided into three layers and each layer being provided with four fans. Width ratio of the tunnel bodies between an expansion section and the contraction section is 1 to 0.54. A rectification section is installed with barriers made of wood boards. An experiment section is 2.0 m by height, 1.3 m by width, and 7.0 m by length, and the top is installed with fluorescent lamps, and toughened glass observation windows are disposed on central positions of the side walls. Wind speed of the wind tunnel is 0-16 m / s, and is continuously adjustable, and the wind tunnel simulates wind gust velocity through adjusting time of acceleration and deceleration of the fans, so the wind tunnel can satisfy study of wheat wind dynamics and lodging-resistant wind speed research.

Owner:HENAN INST OF SCI & TECH

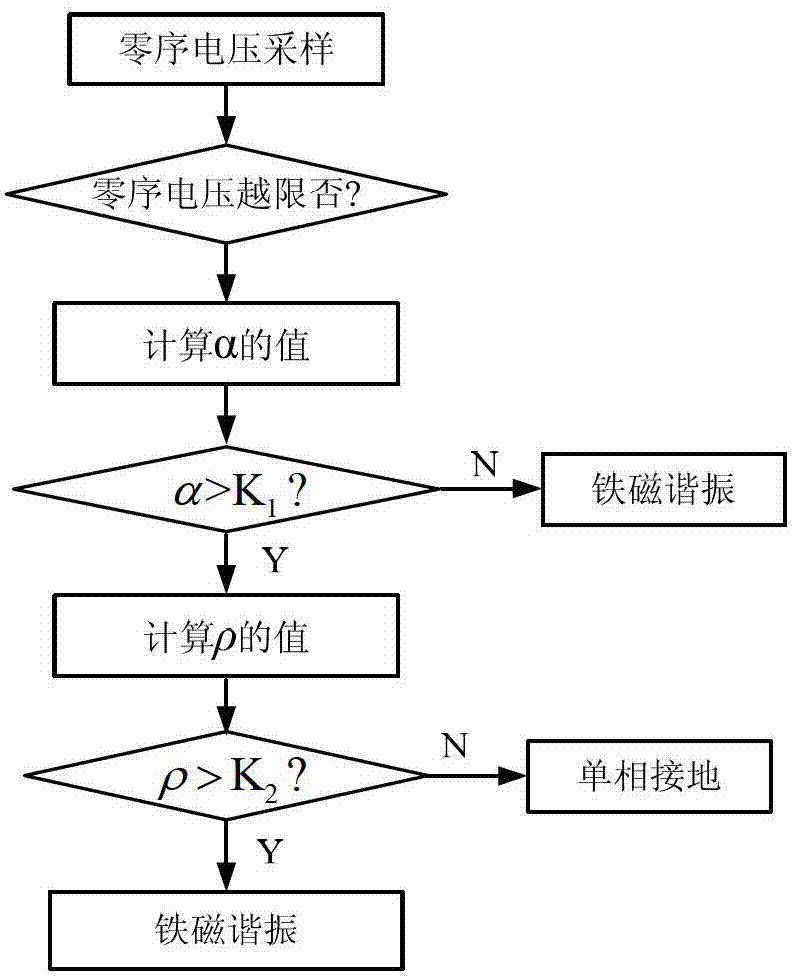

Method of eliminating ferromagnetic resonances

ActiveCN103199514AEliminate ferroresonanceAutomatic recordingElectrical testingEmergency protective arrangements for automatic disconnectionResonanceFundamental frequency

The invention discloses a method of eliminating ferromagnetic resonances. A sine fitting algorithm is utilized to identify ferromagnetic resonances and one-phase grounding faults, according to the method, zero sequence voltage sampling data are subjected to fitting, whether zero sequence voltages are in fundamental frequency quantity can be judged according to the amplitude of a fitting function, wave distortion characteristics of the zero sequence voltages in the fundamental resonances are utilized to construct a wave distortion degree function, and degrees of wave distortion are calculated to distinguish the fundamental resonances and the one-phase grounding. The method has the advantages of being simple in principle, small in calculation amount, and high in sensitivity, the fundamental resonances and the one-phase grounding are accurately distinguished, and moreover ferromagnetic resonance faults are eliminated.

Owner:CHONGQING UNIV

Method for multi-section blocking of covering rock damage band and synchronous leakage measuring

The invention discloses a method for multi-section blocking of overburden failure section and synchronous leakage measuring. The operation step includes boring upcoming holes with 30-50m depth in top-board rock stratum in a coal rock lane, installing a detection system and sending the detection system to the initial position of the bored holes, enclosing the bored holes with a plugging system, sending a water source with specific pressure to a water inlet pipe through a water flooding operating bench, controlling the gas pressure in a plugging capsule to be slightly higher than the gas pressure and the water pressure in a water returning pipe in a blocking chamber, correcting the water pressure in the water returning pipe, measuring the running water vector parameters, starting an electronic recorder and providing corresponding water source pressure after the water pressure in the water returning pipe is adjusted to a reasonable water pressure scope, recording water flow data and other related data after stabilizing, processing and analyzing collected data to form corresponding running water vector graph of the measuring section, and repeating the above steps to sequentially measure the bored holes. Multi-section and synchronous measuring top-board water guiding cracking section at any angle can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

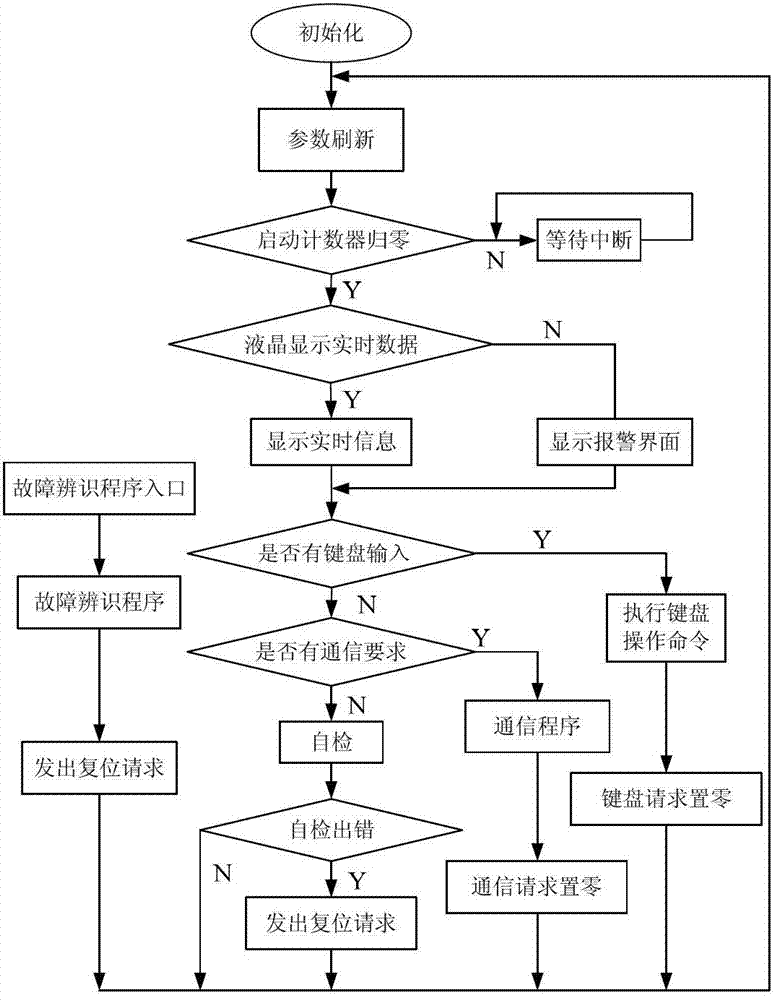

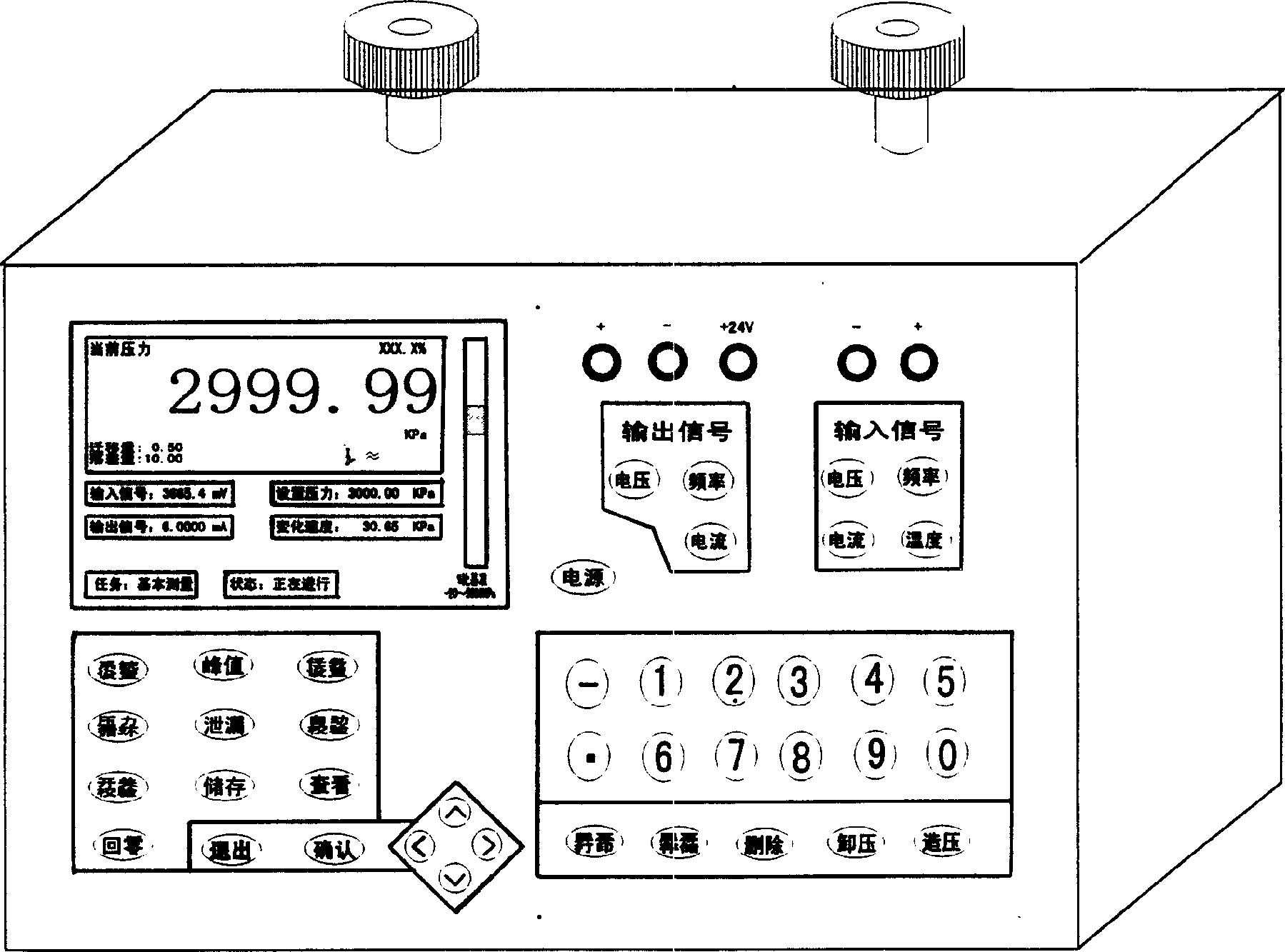

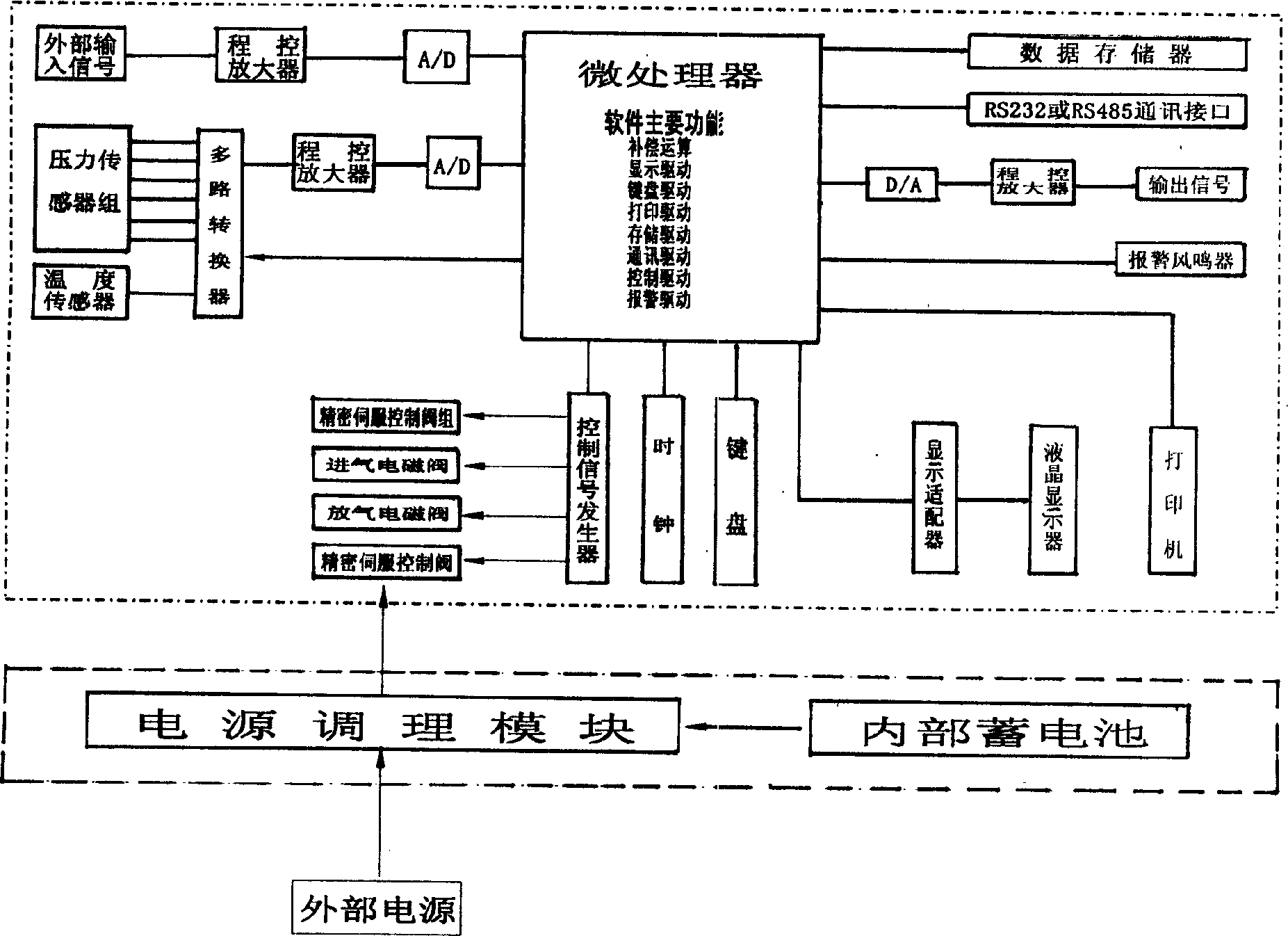

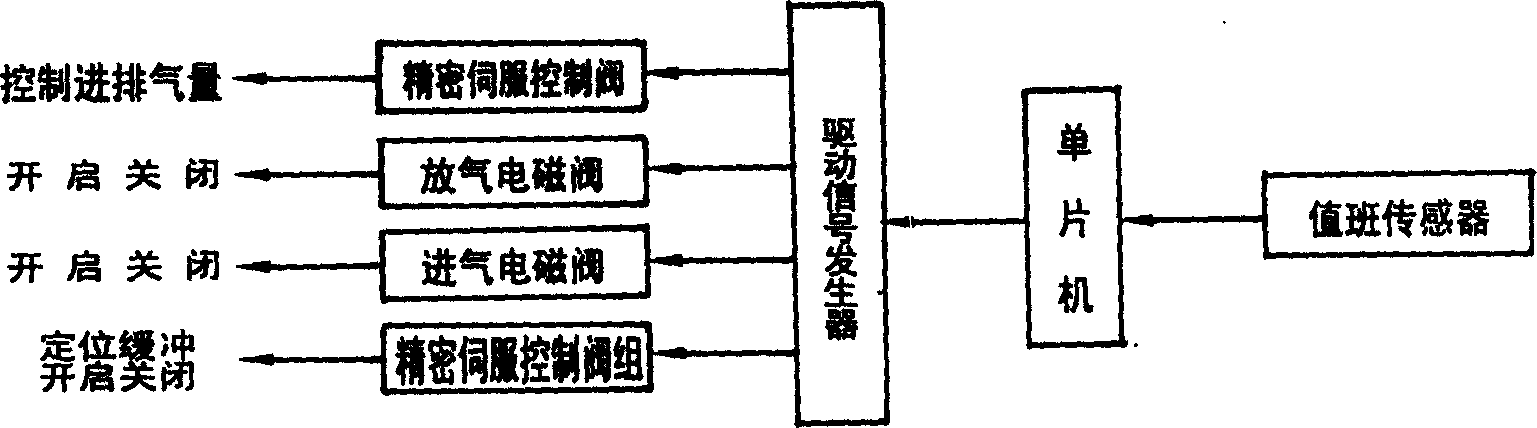

Full-automatic accurate pressure testing control instrument

InactiveCN1595088AAutomatic pressure buildAutomatic measurementFluid pressure measurementMicrocontrollerPressure system

This invention relates to an automatic pressure gage fine control instrument, which can realize the automatic pressure making, automatic pressure stabilizing, automatic measuring, etc in large pressure range. This invention comprises control system, which is separately connected, with pressure system and measurement system. The pressure system is connected with measurement. The control system comprises single machine, which is connected with pressure sensor of the measurement system. The single machine is separately connected with fine servo valves, gas-in magnetic valve, gas-out magnetic valve and fine servo control valve through the control signal generator.

Owner:陕西帅克传感仪器制造有限公司

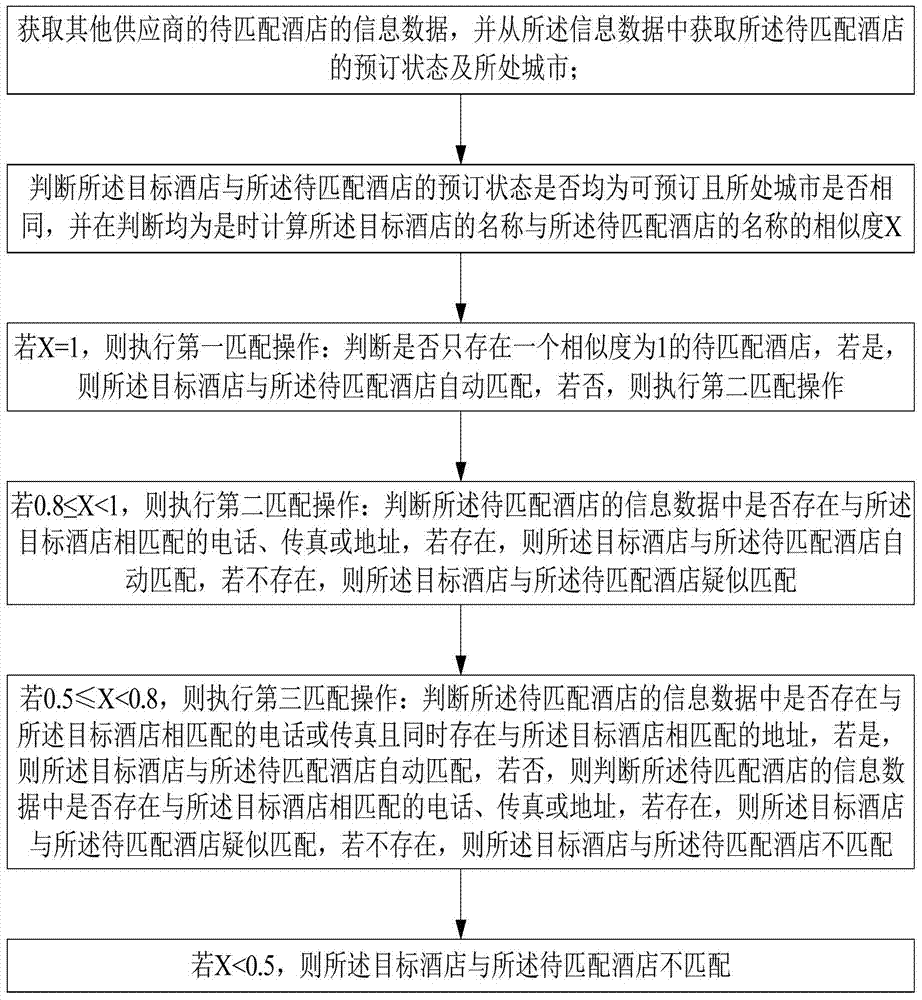

Automatic matching method for hotels

The invention discloses an automatic matching method for hotels. The automatic matching method is used for automatically matching target hotels of target suppliers and comprises the following steps: acquiring information data of the hotels to be matched of other suppliers, and acquiring reservation statuses of the hotels to be matched and cities where the hotels to be matched are positioned from the information data; judging whether the preservation statues of the target hotels and the reservation statues of the hotels to be matched are both reservable or not and the cities where the target hotels are positioned are identical with the cities where the hotels to be matched are positioned or not, calculating the similarity X of names of the target hotels and names of the hotels to be matched when the judgment result is yes; if X is equal to 1, executing first matching operation; if X is greater than or equal to N and less than 1, executing second matching operation; if X is greater than or equal to 0.5 and less than N, executing third matching operation; if X is less than 0.5, judging that the target hotels are mismatched with the hotels to be matched. According to the automatic matching method disclosed by the invention, the matching relation of multi-platform hotels can be calculated and recorded intelligently, accurately and automatically, the matching rate can be improved, and the matching accuracy can be guaranteed.

Owner:CTRIP COMP TECH SHANGHAI

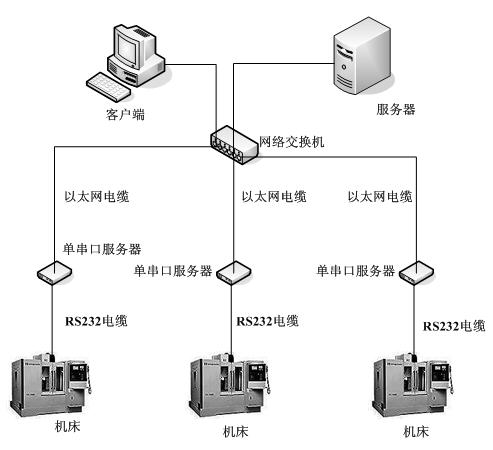

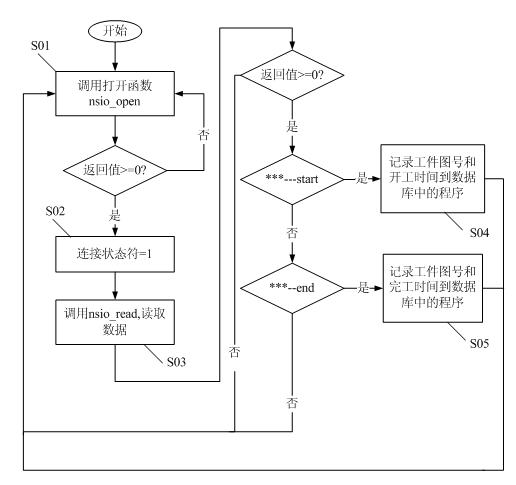

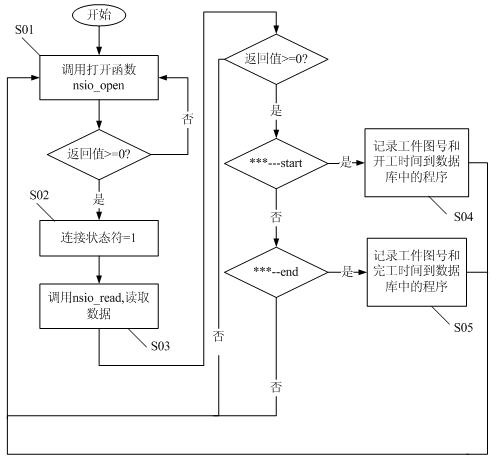

Method for monitoring numerical control machine

InactiveCN102495591AAccelerateSave human resourcesProgramme controlComputer controlNumerical control systemStart time

The invention provides a method for monitoring a numerical control machine, which comprises the following steps of: firstly, building a numerical control machine monitoring system; then establishing a database which is in a table format on a server; developing a corresponding functional module interface on a client; programming a numerical control program on the numerical control machine according to an adopted programming rule of a numerical control system; receiving information sent by the numerical control machine by the server through calling a function in a single serial port server; processing according to read program data; recording a workpiece drawing number and start time into the database; and recording a workpiece drawing number and completion time into the database. Accordingto the invention, the work of recording the workpiece drawing numbers, the machining start and completion time and machining working hours of workpieces when the workpieces are machined on the numerical control machine can be completed, the automatic recording is realized, and the has advantages of high speed, manpower resource saving and low cost are achieved.

Owner:JIANGNAN UNIV

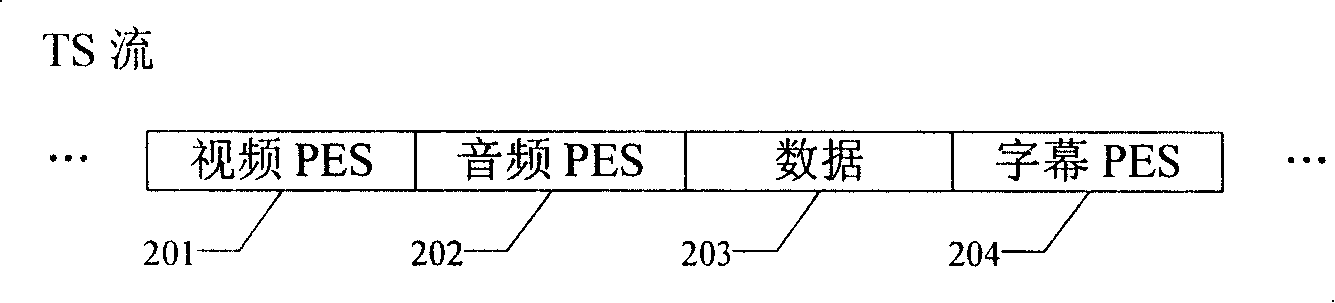

Program recording method and recording device thereof

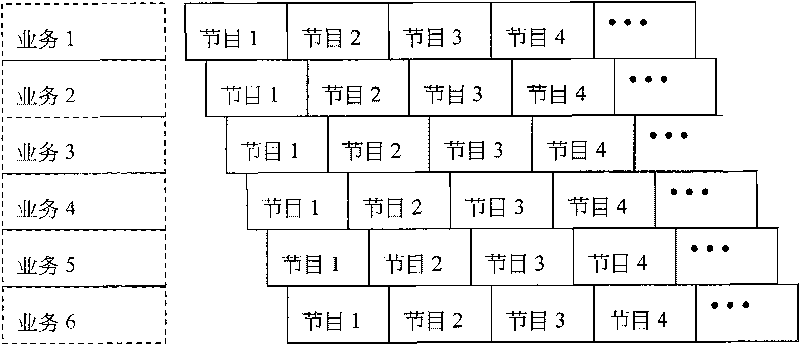

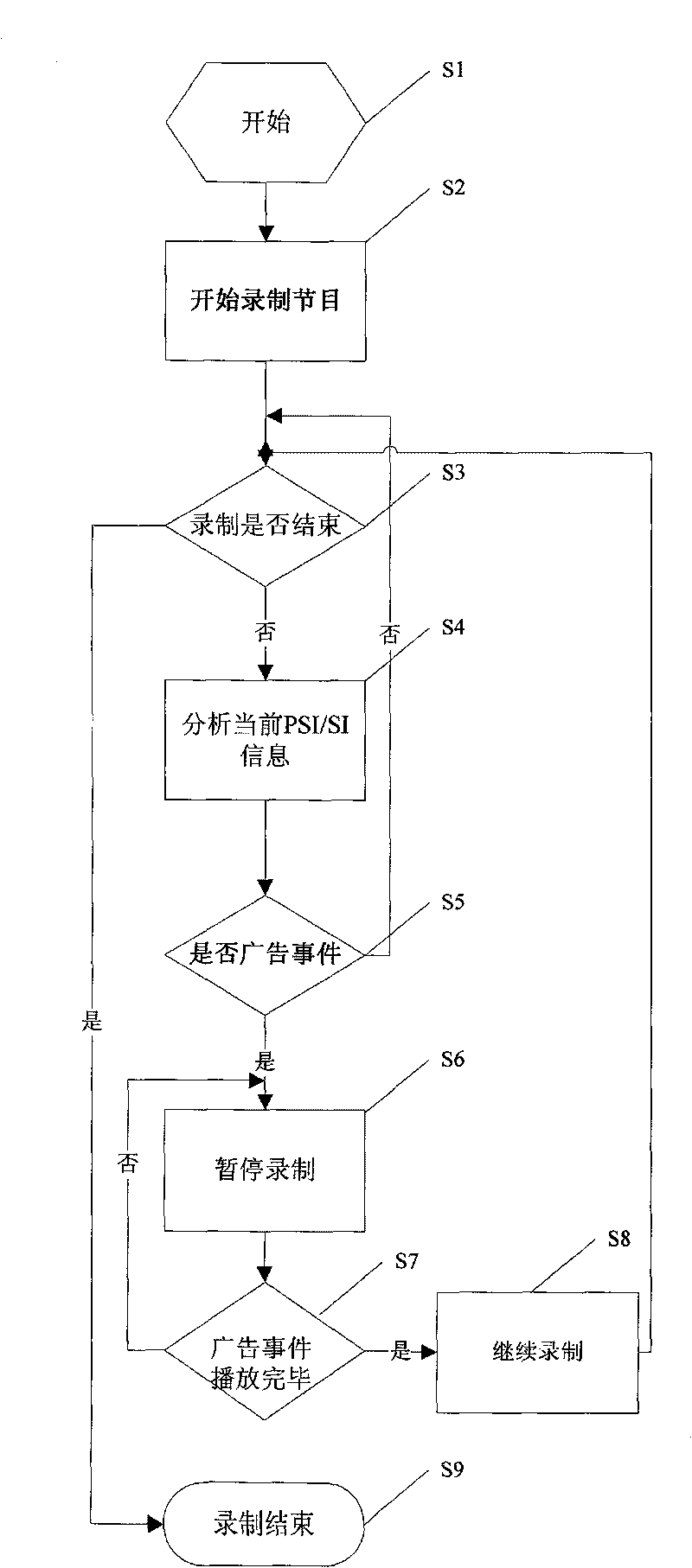

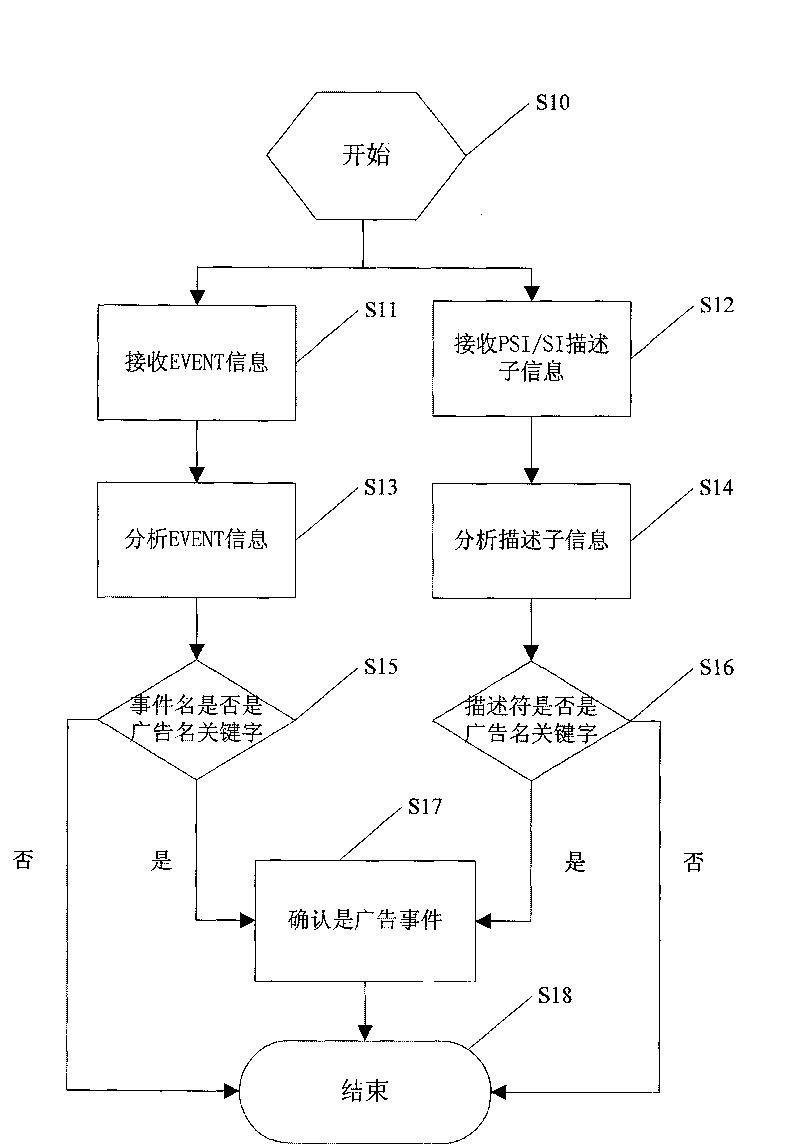

ActiveCN101692702AAutomatic recordingFull recordingTelevision system detailsPulse modulation television signal transmissionTime informationData stream

The invention discloses a program recording method comprising: processing a service description table in a data flow to obtain the program number of a target service; processing a program event information table in the data flow to obtain program information; according to a program required to be recorded, searching reference event information from program information; according to the obtained reference event information, obtaining time information corresponding to each event; judging whether each event is carried out at the same frequency point; if yes, synchronously recording programs; and if no, automatically recording programs one by one. The invention also relates to a recording device which can integrally record target content and filter advertisement information.

Owner:HISENSE VISUAL TECH CO LTD

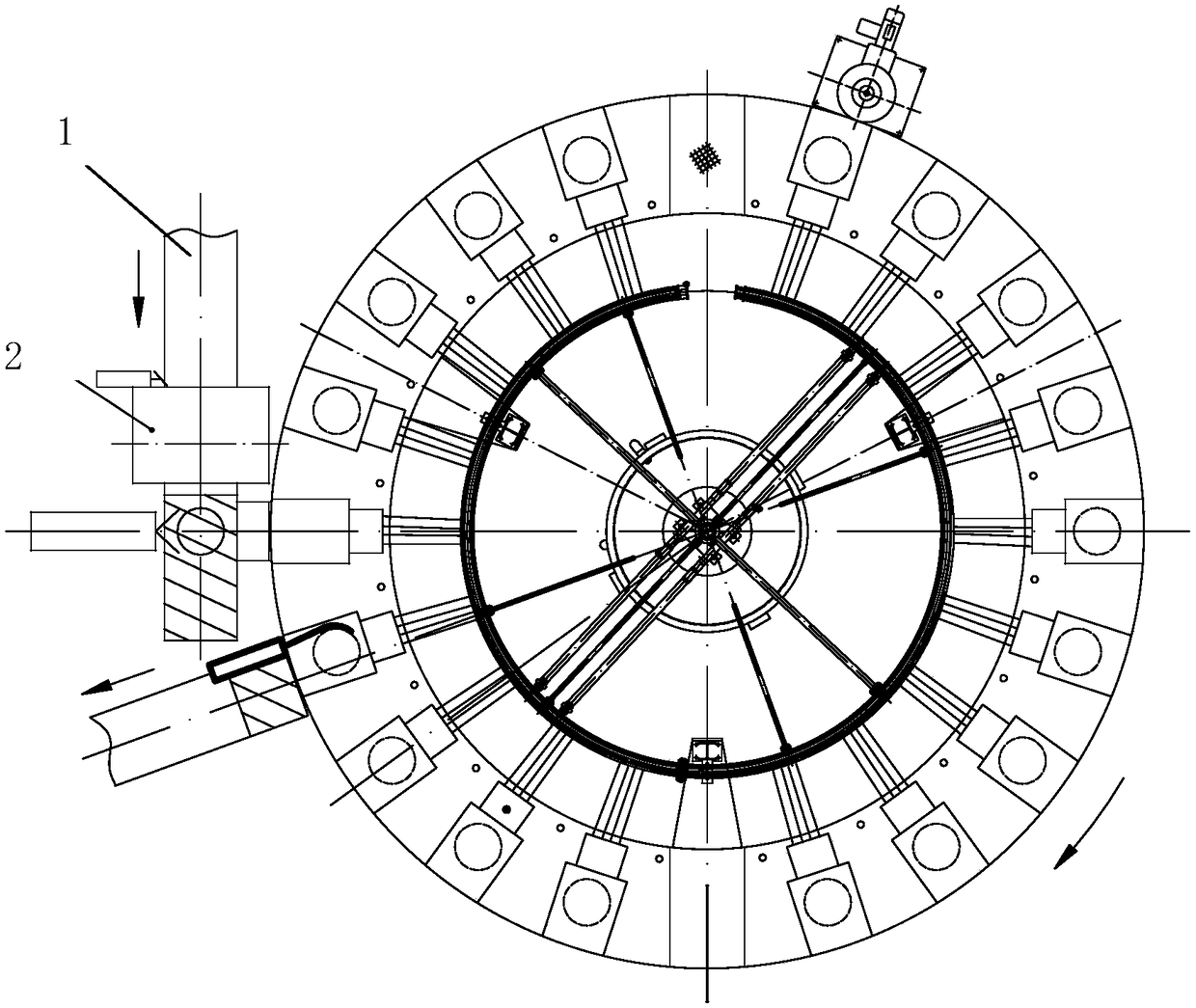

Steel rail ultrasonic on-line detection system and control method thereof

ActiveCN102818848AWide detection rangeMultiple track typesAnalysing solids using sonic/ultrasonic/infrasonic wavesRailheadEngineering

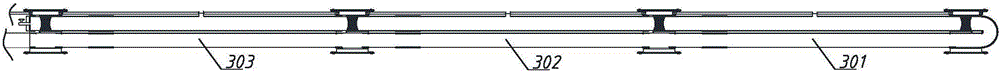

The invention provides a steel rail ultrasonic on-line detection system and a control method thereof. The steel rail ultrasonic on-line detection system comprises a support, a roller way, a railhead tread undercarriage, a rail base undercarriage, a railhead right undercarriage, a railhead left undercarriage, a rail web left undercarriage, ultrasonic probes, a photoelectric correlated cell I, a photoelectric correlated cell II, a photoelectric correlated cell III, a photoelectric correlated cell IV, a steel rail position detection device, a steel rail shape detection device, a controller and an ultrasonic tester. When the photoelectric correlated cells induct a steel rail, the controller controls the corresponding undercarriage to lift or drop so that the ultrasonic probe on the corresponding undercarriage is driven to act and thus flaw detection on all parts of the steel rail is realized. When an internal defect of a steel rail is found, the steel rail position detection device outputs a specific position of the internal defect of the steel rail and flaw detection is stopped. The steel rail ultrasonic on-line detection system has the advantages of wide detection range, fast detection rate and high detection precision.

Owner:四川曜诚无损检测技术有限公司

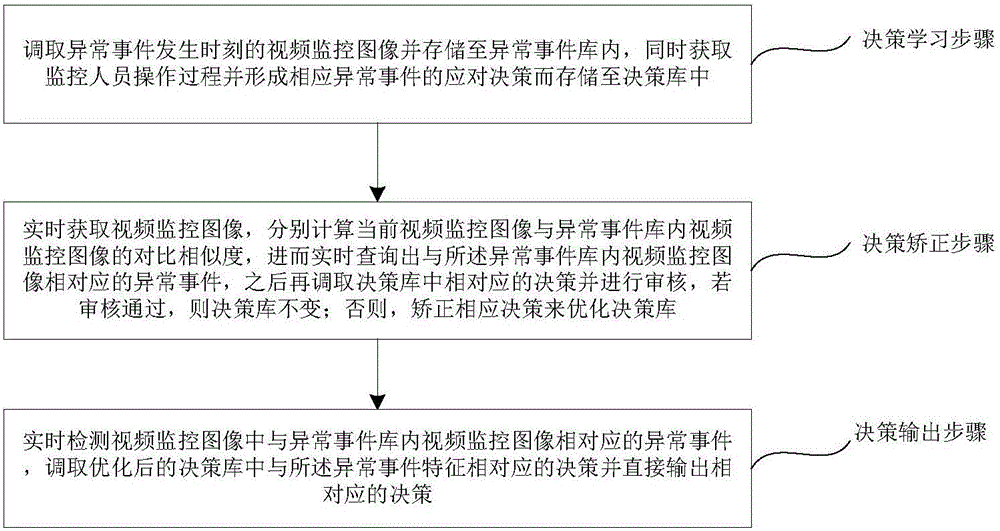

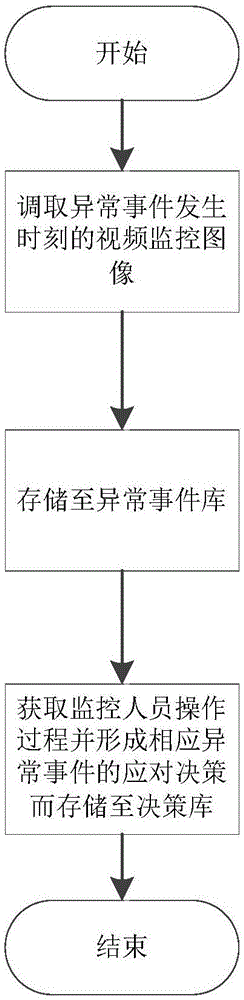

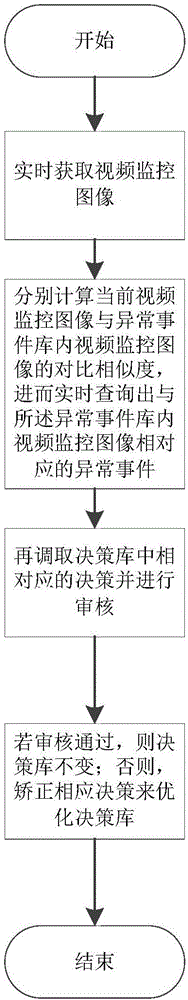

Image identification-based security intelligent decision-making method and system

ActiveCN106851229AConnect in timeImprove security automationCharacter and pattern recognitionClosed circuit television systemsVideo monitoringImage identification

The invention discloses an image identification-based security intelligent decision-making method and system. The method comprises the steps of transferring a video monitoring image at the moment of occurrence of an abnormal event, storing the video monitoring image into an abnormal event base, simultaneously obtaining a monitoring personnel operation process and forming a coping decision of the corresponding abnormal event to store into a decision-making base; obtaining the video monitoring image in real time, calculating the contrast similarity of a current video monitoring image and the video monitoring image in the abnormal event base separately to query the abnormal event corresponding to the video monitoring image in the abnormal event base in real time, and then transferring the corresponding decision from the decision-making base and auditing the decision; if the audit pass, keeping the decision-making base invariable; or else, correcting the corresponding decision to optimize the decision-making base; and detecting the abnormal event corresponding to the video monitoring image in the abnormal event base in the video monitoring image in real time, transferring the decision corresponding to abnormal event characteristics from the optimized decision-making base and directly outputting the corresponding decision.

Owner:山东瀚岳智能科技股份有限公司

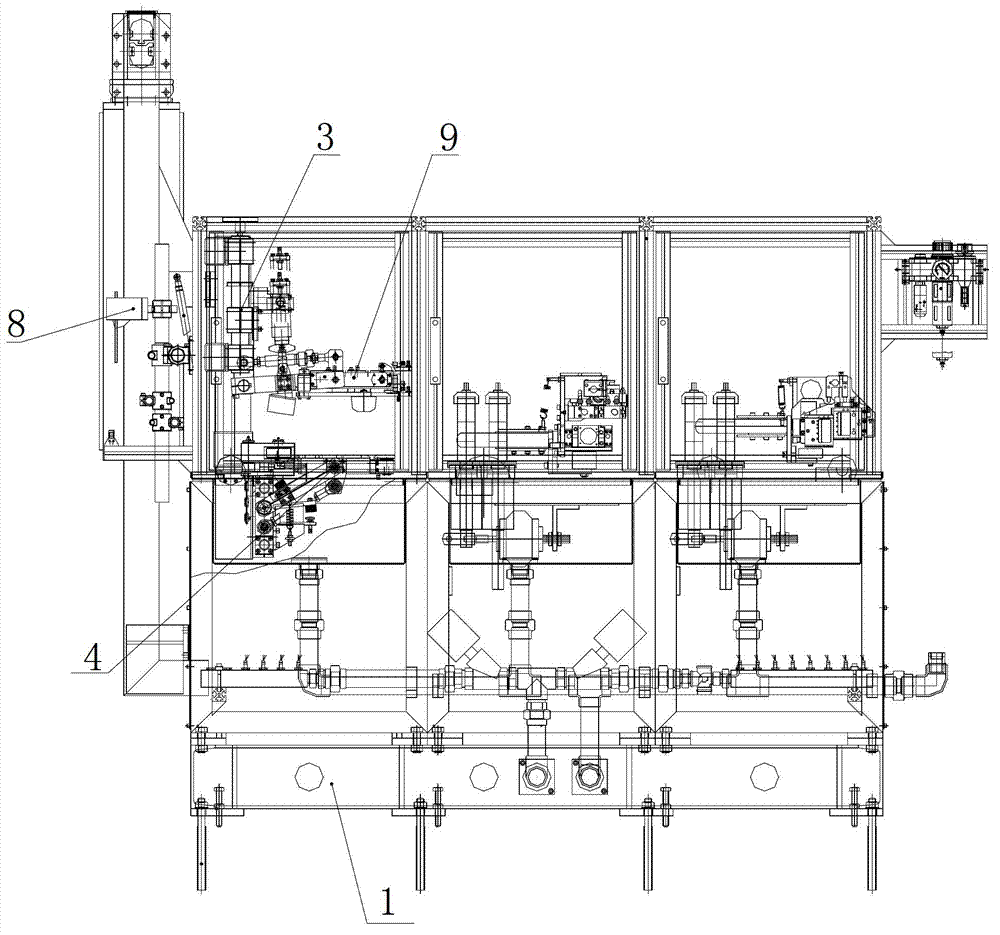

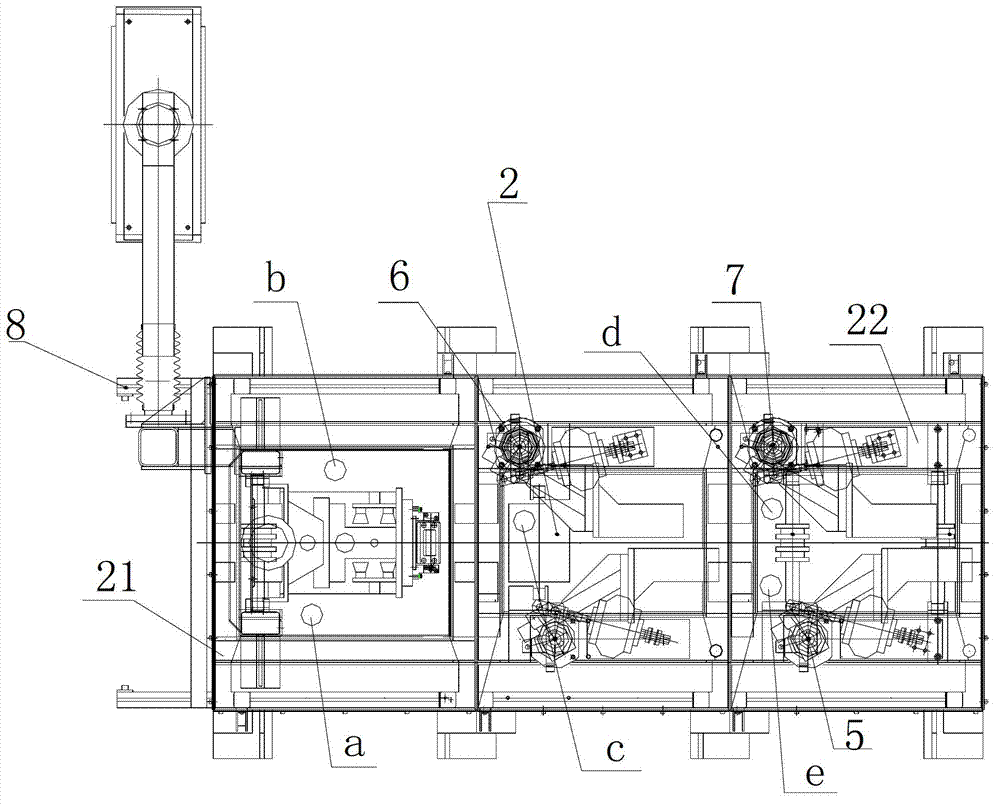

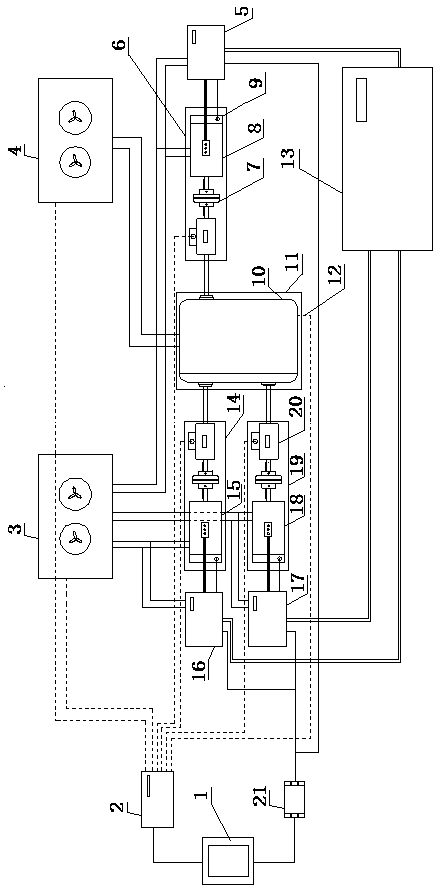

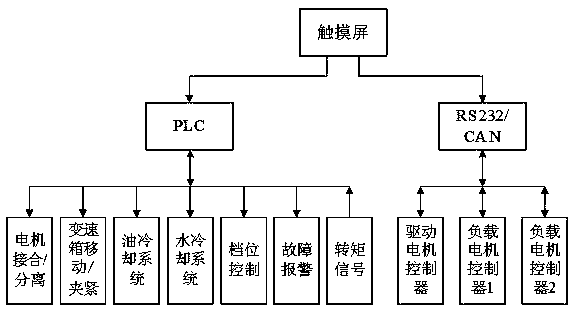

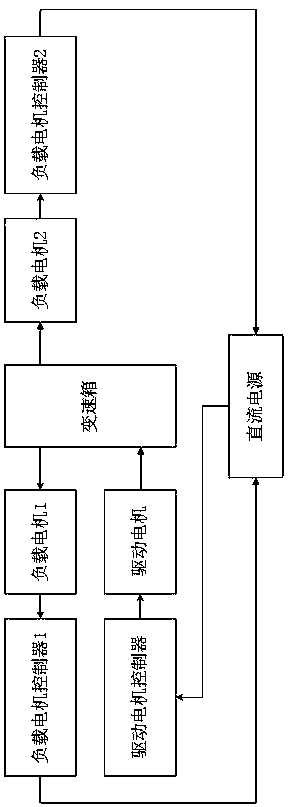

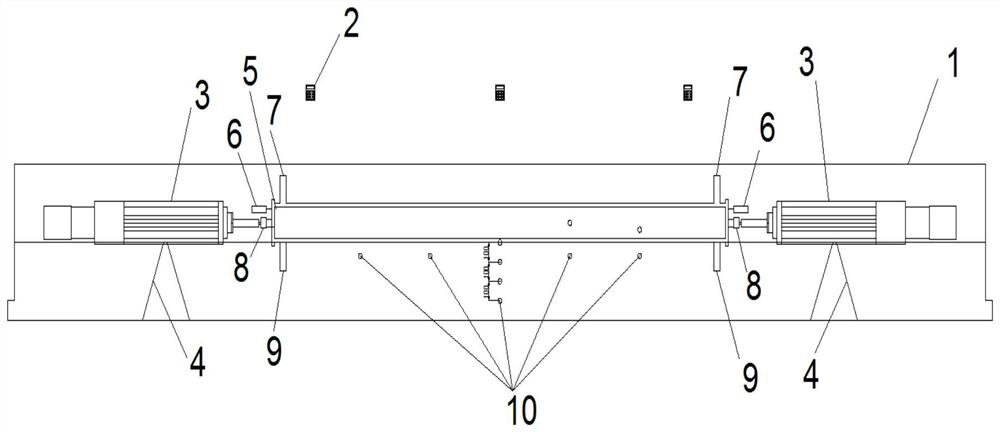

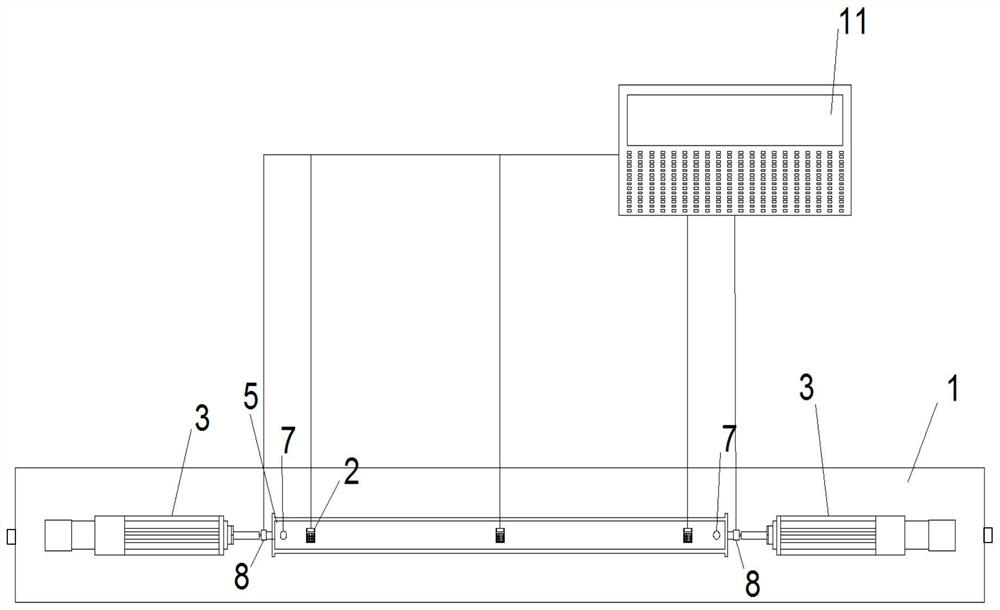

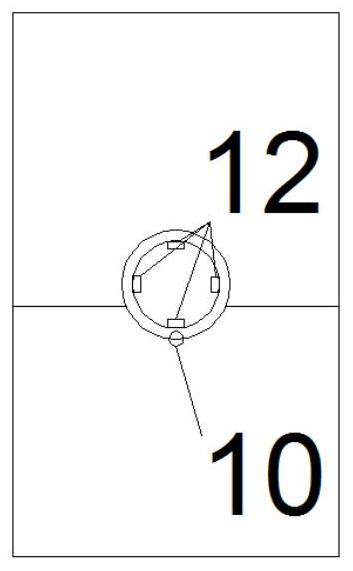

Online detection bench for gearbox and detection method

InactiveCN108982098AWith self-test functionGuaranteed uptimeVehicle testingMachine gearing/transmission testingProgrammable logic controllerControl line

The invention discloses an online detection bench for a gearbox and a detection method. At present, the traditional automobile gearbox detection load side is mostly energy-consuming load, and energy recycling cannot be achieved. The online detection bench for the gearbox comprises a touch screen (1); the touch screen is connected with a programmable logic controller PLC (2) and an RS232 / CAN communication converter (21) through Ethernet and an RS232 serial port line respectively; the PLC is respectively connected with a water cooling system (3) and an oil cooling system (4) through a control line; the oil cooling system is connected with the gearbox (10) through an oil cooling circuit; the water cooling system is connected with a load motor controller II (5) and a load motor II (8) respectively through a water cooling circuit; the load motor controller II is connected with a DC power supply (13) through a bus; and the DC power supply is connected with a driving motor controller (17) anda load motor controller I (16) through a bus. Thus, the online detection bench for the gearbox is disclosed.

Owner:HARBIN UNIV OF SCI & TECH

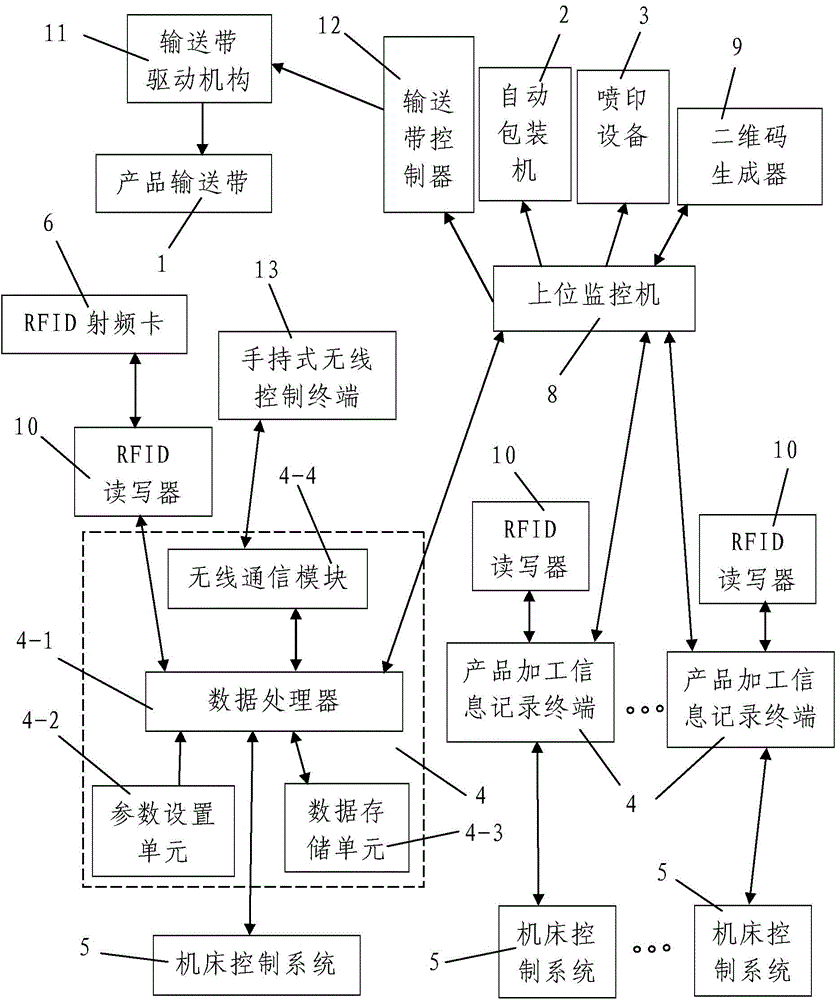

Numerically-controlled machine tool processing production line based on RFID radio-frequency card

The invention discloses a numerically-controlled machine tool processing production line based on an RFID radio-frequency card. The numerically-controlled machine tool processing production line is composed of an upper monitoring machine, a product conveying belt, a plurality of numerically-controlled machine tools, an automatic packaging machine for packaging finished products after processing completion, a two-dimensional code generator for generating a two-dimensional code with processing information stored internally, and a printing device for printing the generated two-dimensional code on a packaging box processed by the automatic packaging machine. The multiple numerically-controlled machine tools, the automatic packaging machine, and the printing device are arranged along the product conveying belt from front to back. A clamping mechanism is arranged on the product conveying belt and a horizontal clamp groove is formed in the rear side of the clamping mechanism. Each numerically-controlled machine tool is provided with a product processing information recording terminal. According to the invention, the provided numerically-controlled machine tool processing production line has advantages of simple structure, reasonable design, simple and convenient operation and usage, and good using effect. When a product is process, processing information of the product can be recorded automatically and can be stored into a two-dimensional code printed on the outer side of a packaging box, so that any consumer can query the information conveniently.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

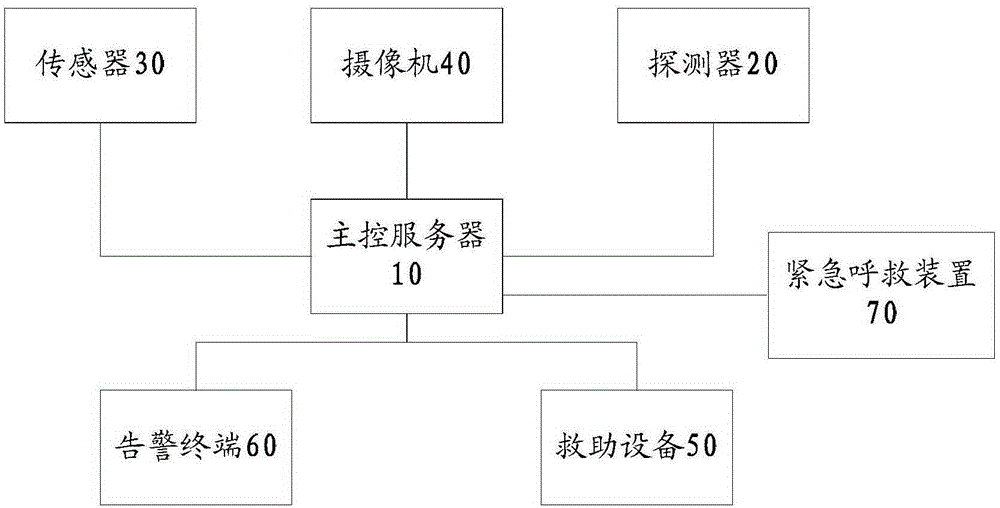

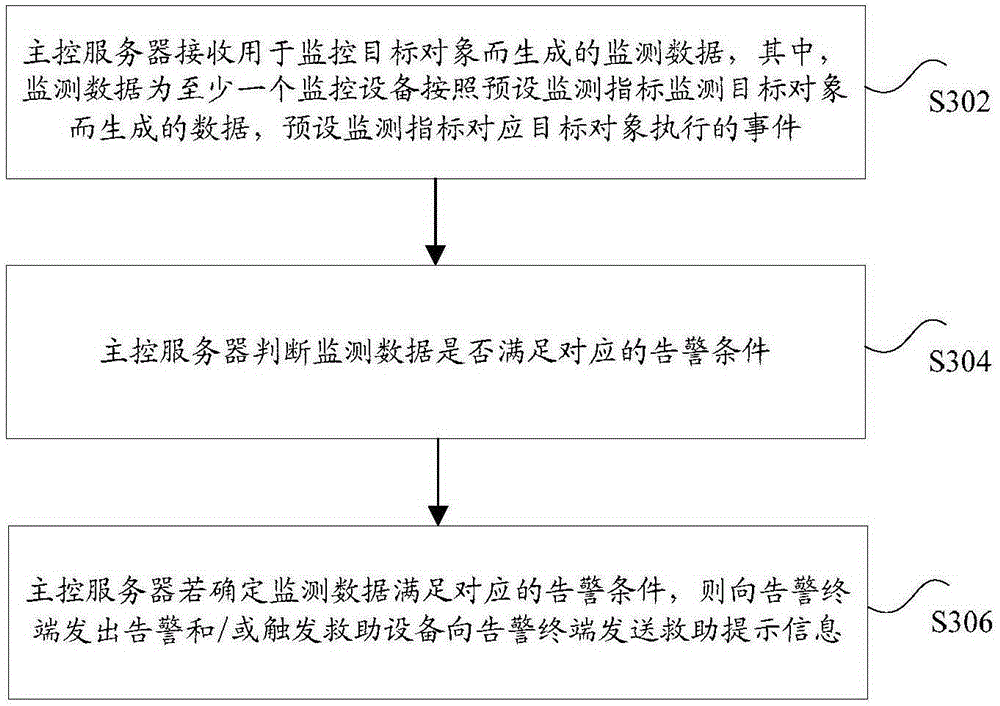

Intelligent monitoring method and intelligent monitoring system

ActiveCN106485877ATimely rescueThe rescue equipment sends rescue to the alarm terminal in timeAlarmsMonitoring statusMonitoring system

The invention discloses an intelligent monitoring method and an intelligent monitoring system, wherein the method comprises the steps of receiving monitoring data which are generated for monitoring an objective target by a master control server, wherein the monitoring data are generated in monitoring the objective target by at least one set of monitoring equipment according to a preset monitoring index, wherein the preset monitoring index corresponds with an event which is executed by the objective target; determining whether the monitoring data satisfy a corresponding alarm condition by the master control server; and if the master control server determines a fact that the monitoring data satisfy a corresponding alarm condition, transmitting alarm to an alarming terminal and / or triggering helping equipment to transmit helping reminding information to an alarm terminal. The intelligent monitoring method and the intelligent monitoring system settle technical problems of single function and insufficient linkage between components in the monitoring system which is supplied in related technology.

Owner:HANGZHOU EZVIZ NETWORK CO LTD

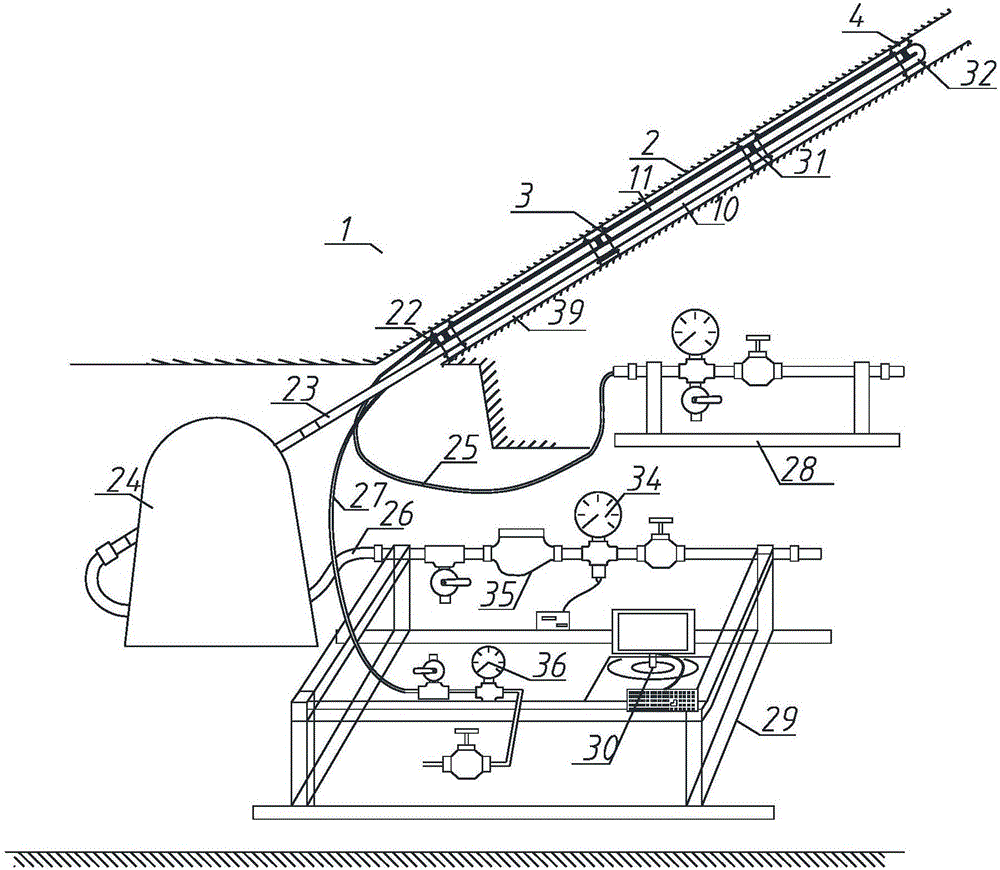

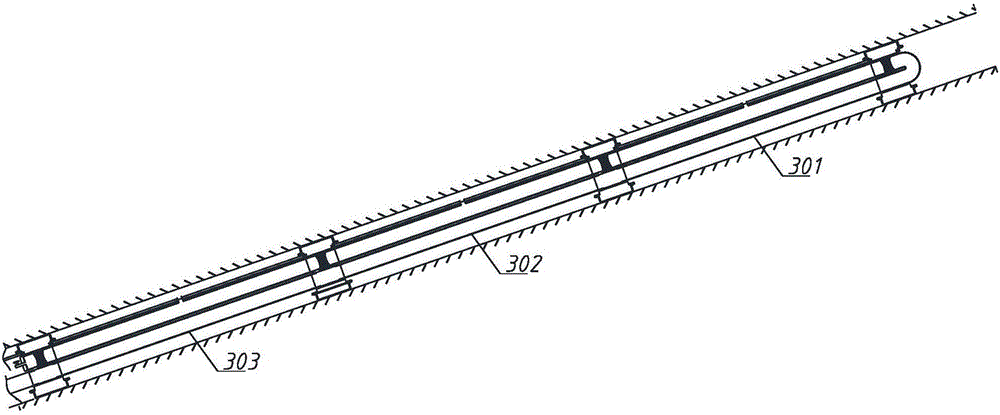

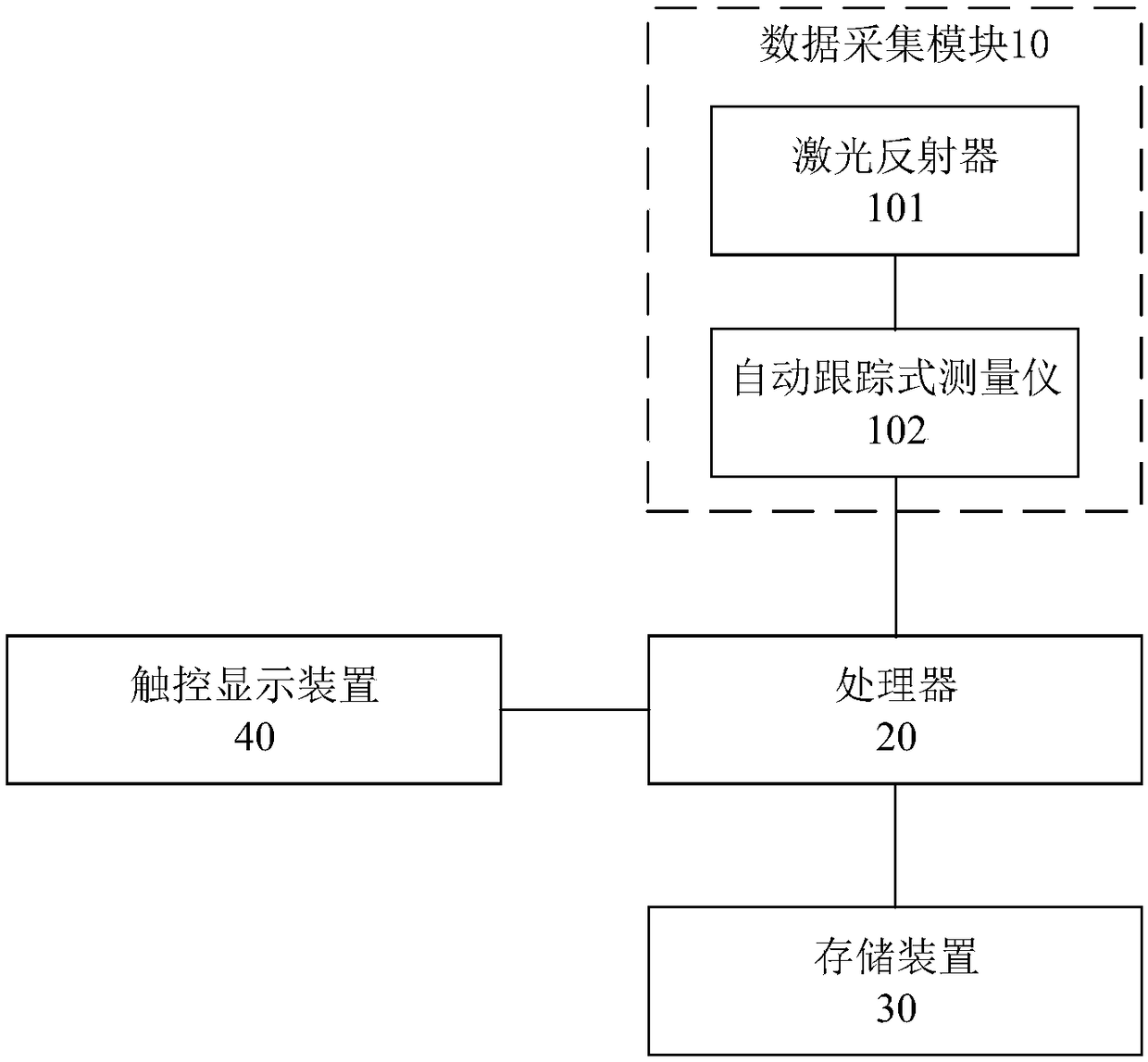

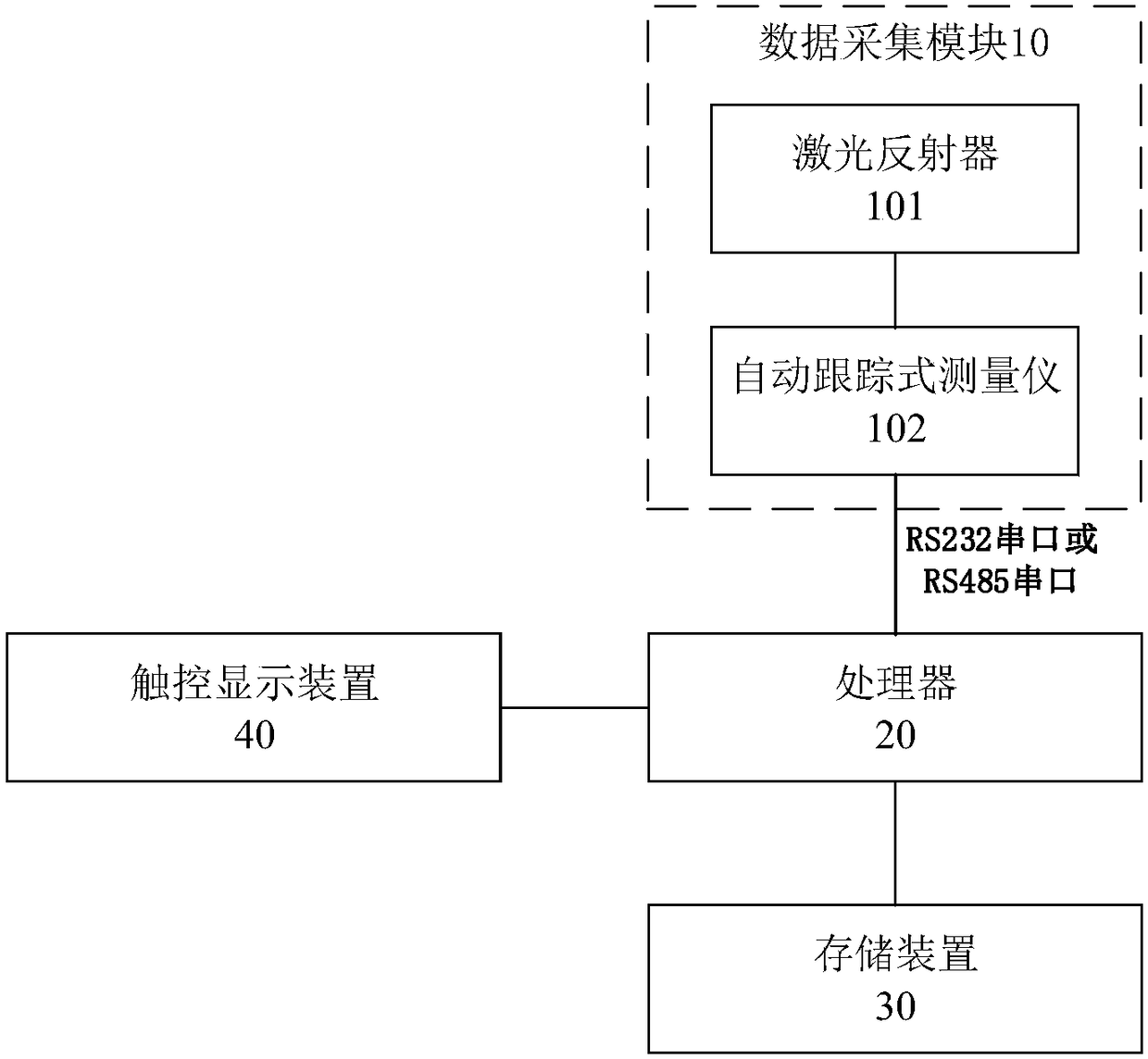

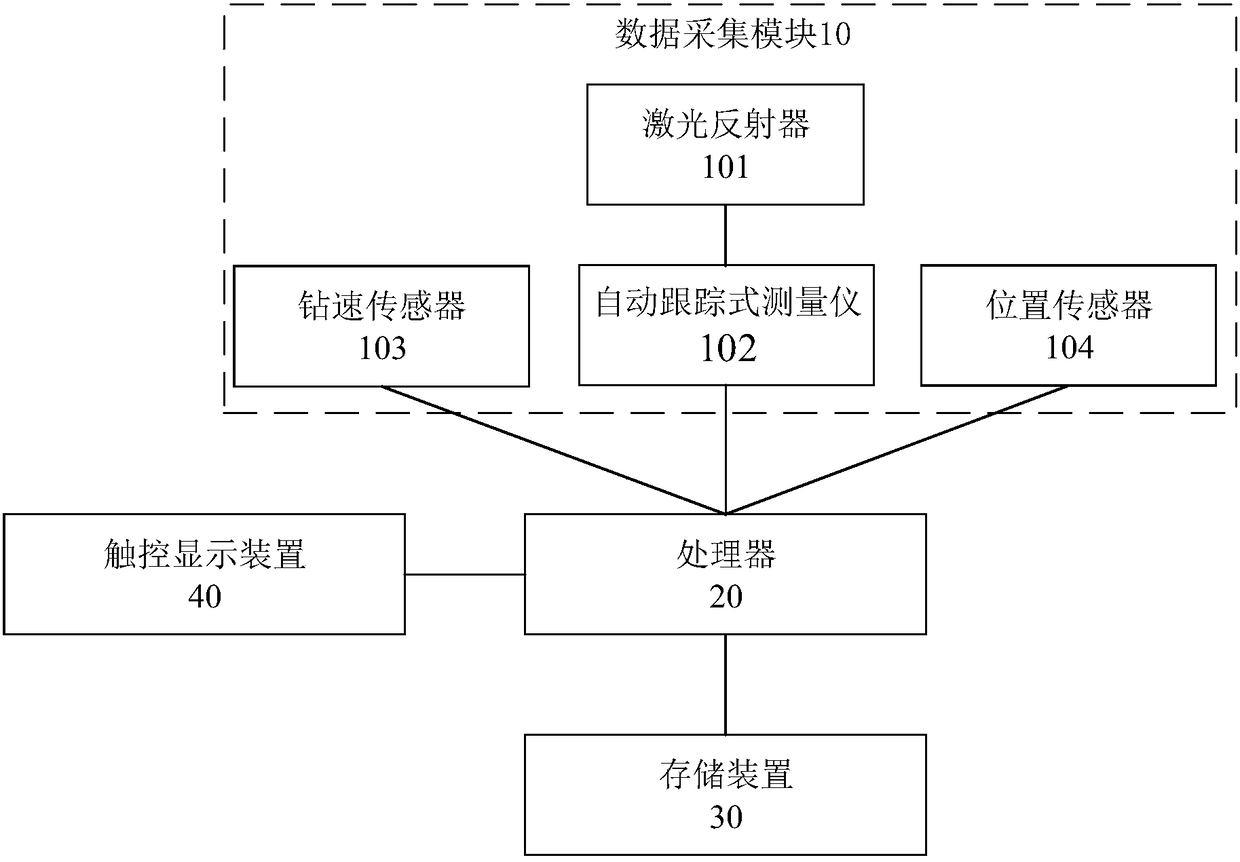

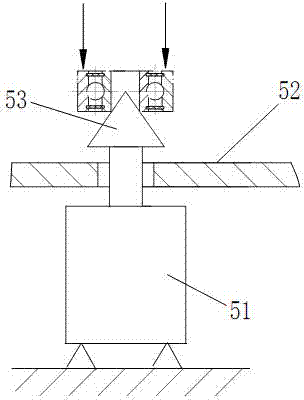

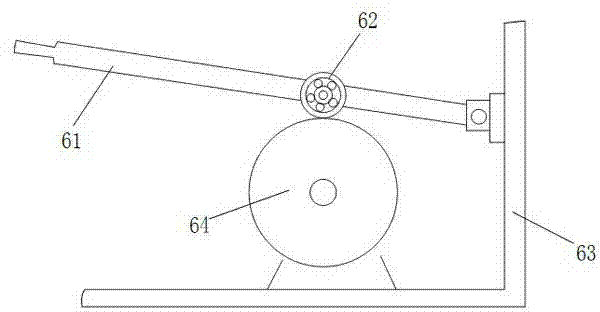

Data acquisition system for anchor drilling rig

ActiveCN108222985AAutomatic recordingReal-time recordingMining devicesTotal factory controlMeasuring instrumentState parameter

The invention relates to a data acquisition system for an anchor drilling rig. The data acquisition system comprises a data acquisition module, a processing unit, a storage unit and a touch-control display unit, wherein the data acquisition module is used for acquiring parameter of operating states of the anchor drilling rig and comprises a laser reflector and an automatic tracking type measuringinstrument, and the automatic tracking type measuring instrument is used for tracking the laser reflector to acquire drilling position and angle; the processing unit is used for collecting the parameter of operating states acquired by the data acquisition module and saving the parameter of operating states into the storage unit, displaying the parameter of operating states through the touch-control display device, monitoring operating states of the anchor drilling rig, and sending an exception warning when monitoring the exception of the operating states. Therefore, the data acquisition systemcan automatically record the parameter of operating states of the anchor drilling rig in real time, facilitates parameter storing, referring in the future and engineering quality tracing, and effectively solves the problems of low efficiency, poor traceability and low data reliability of operating data recorded manually.

Owner:山西新能正源智能装备有限公司

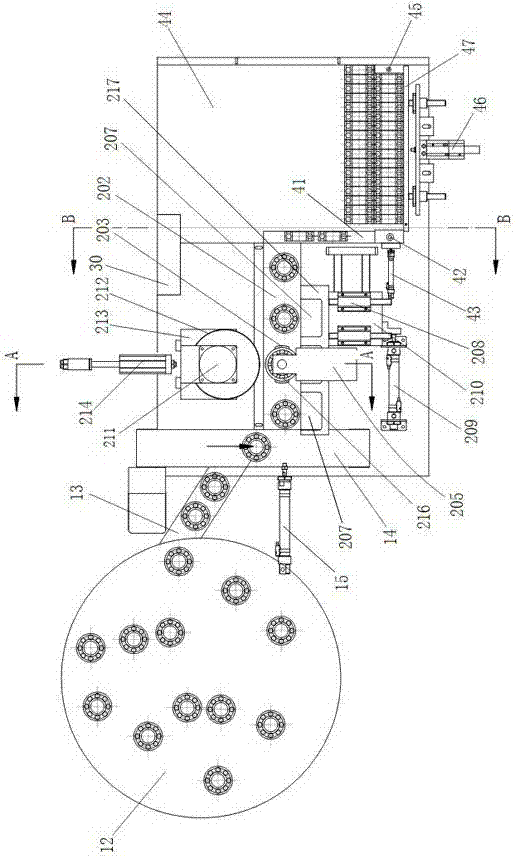

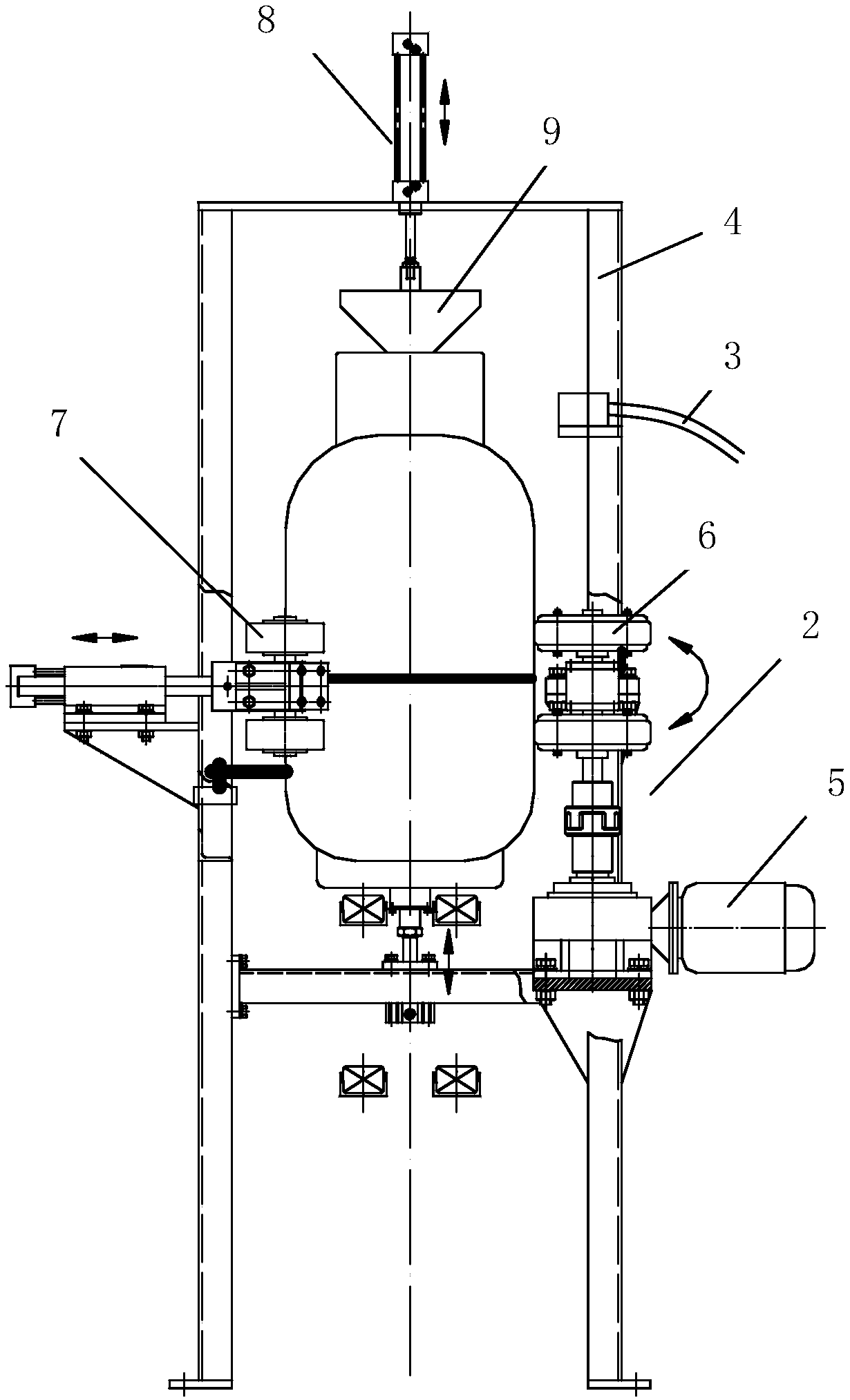

Full-automatic bearing grease evening machine

ActiveCN104776124AHigh degree of automationUniform fatBearing componentsEngineeringMechanical engineering

The invention relates to a full-automatic bearing grease evening machine. The full-automatic bearing grease evening machine comprises a feeding mechanism, a grease evening mechanism and an arraying mechanism. The feeding mechanism comprises a rotating drum, a conveying belt connected with an output port of the rotating drum and a first material pushing air cylinder located at one side of the conveying belt. Multiple bearing necks are formed in one side of a grease evening channel. The bearing necks are driven by a neck horizontal air cylinder to move horizontally to the grease evening channel, and then the bearing necks are driven by a neck vertical air cylinder to move vertically to the grease evening channel. A bearing jacking rod for jacking a bearing is arranged at the lower end of the grease evening channel of the grease evening mechanism. The bearing jacking rod jacks the bearing until an inner ring of the bearing abut against a pressing plate. A grease evening motor, a grease wheel, a grease evening support and a grease evening support air cylinder are vertically arranged at the other side of the grease evening channel. The arraying mechanism forms the bearings with the grease is evened to multiple arrays. The full-automatic bearing grease evening machine has the advantages that the inner ring fixes an outer ring to even grease in a rotated mode, sufficient and fixed grease evening time can be guaranteed, the load born by the bearing during grease evening can be adjusted and fixed, the speed of grease evening can be adjusted, and the automatic degree is high.

Owner:BH TECH GRP CO LTD

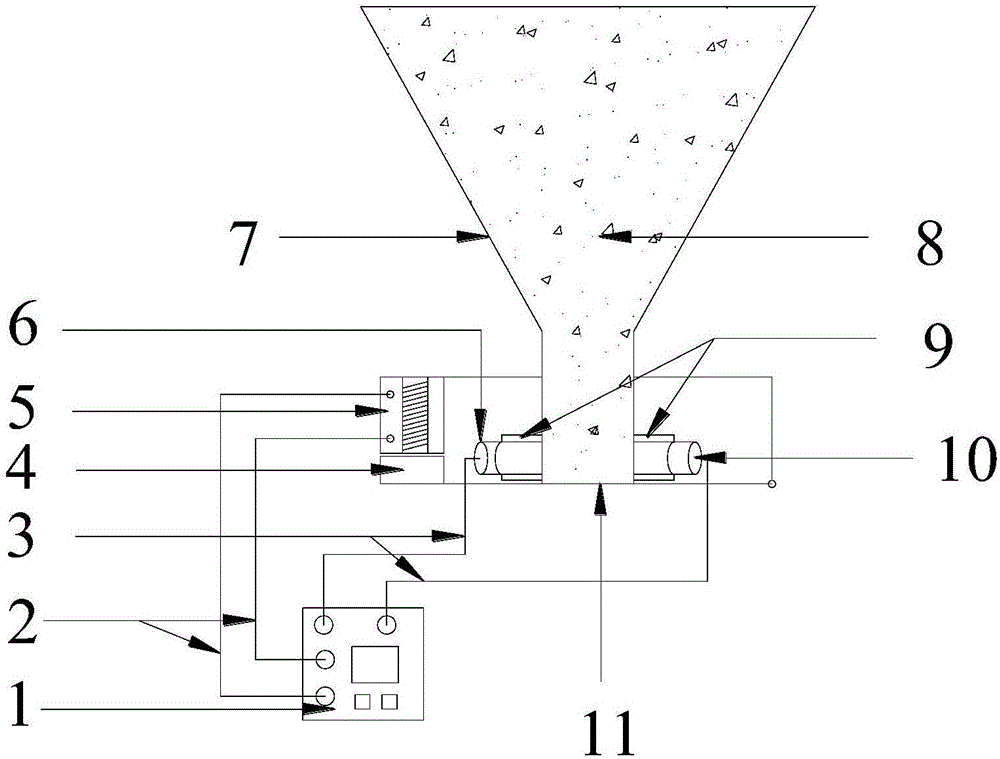

Highly precise V-shaped funnel measurement apparatus of cement paste

PendingCN106596339AEffectively fixedEasy to install and removeVolume/mass flow measurementDirect flow property measurementData transmission systemsSurface plate

The invention relates to a highly precise V-shaped funnel measurement apparatus of a cement paste. The apparatus comprise an electromagnetic system, a probe control system, a data transmission system, a data receiving system and a data analysis system. An electromagnetic field converter 5 controls the closure and the opening of a funnel leakage preventing support plate, an ultrasonic emitter 6 and an ultrasonic receiver 10 are respectively fixed in measuring points at two sides of the outlet of a V-shaped funnel by annular buckles 9, ultrasonic test data is transmitted to the control system 1 through an ultrasonic data line 3, the control system 1 immediately analyzes and records the data, and the flowing duration of the paste in the funnel is displayed on a display panel. The apparatus adopting the electromagnetic system and the ultrasonic system realizes fully-automatic, highly-precise and highly-efficient recording of the flow duration of the cement paste in the V-shaped funnel, and solves the problem of low timing precision of the V-shaped funnel.

Owner:TSINGHUA UNIV

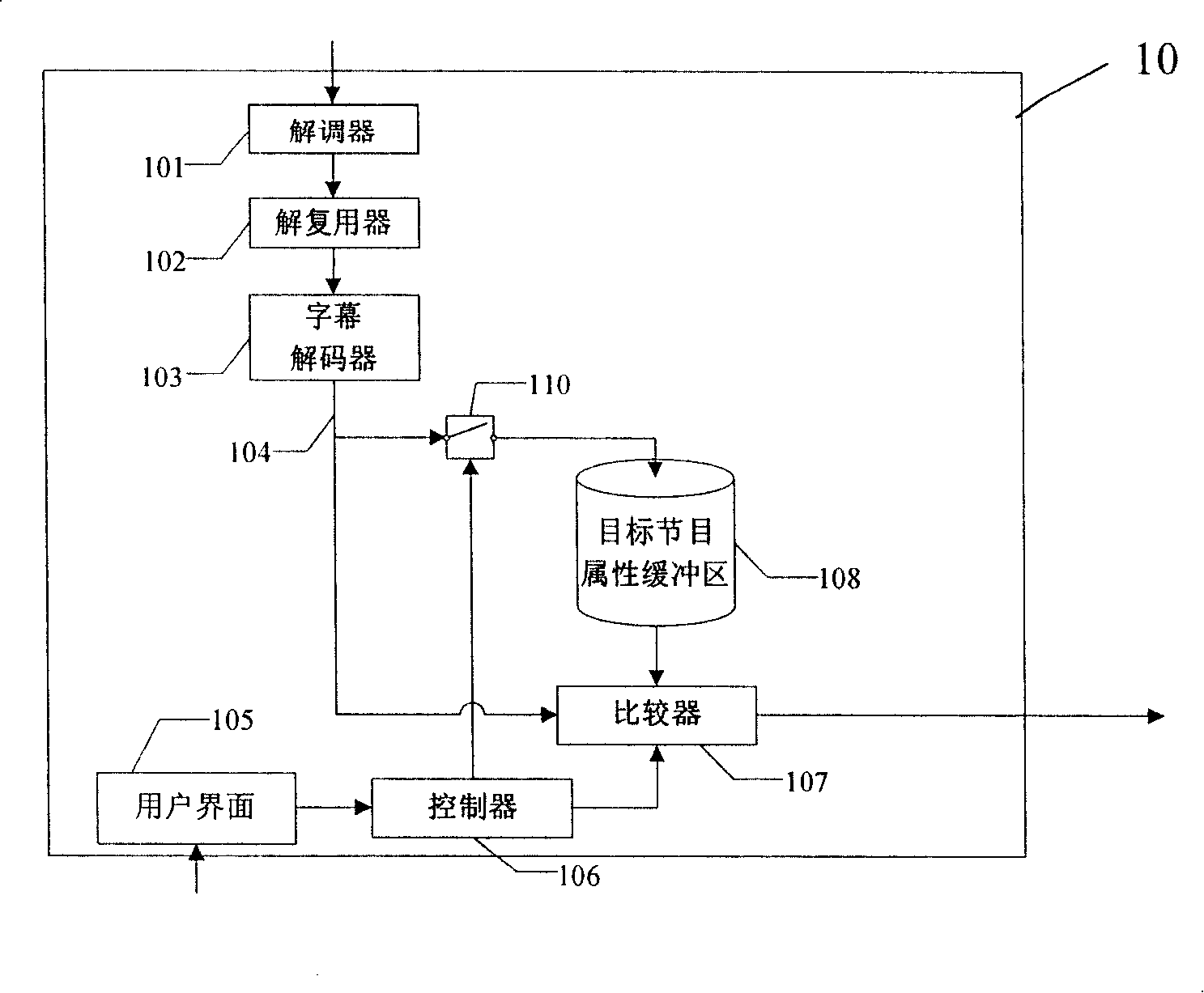

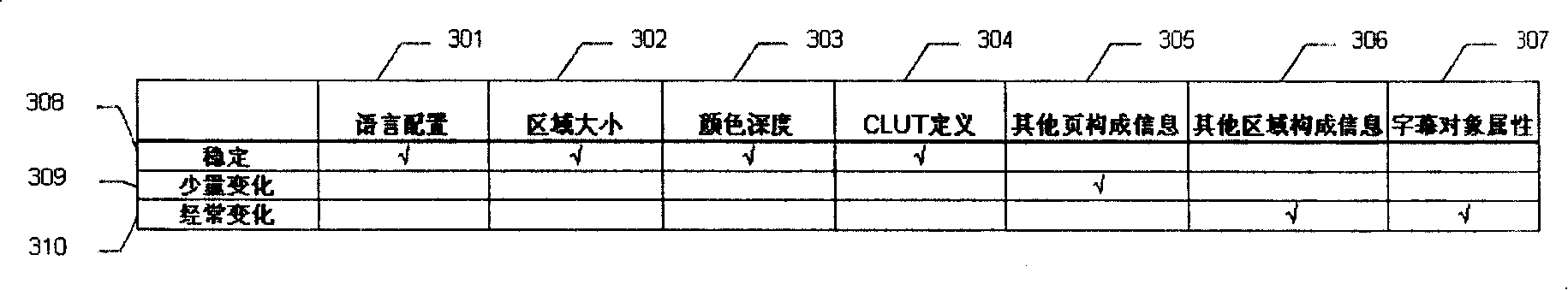

Equipment and method for detecting telecast commutation

InactiveCN101175167AThe test result is accurateTell in timeTelevision system detailsColor television detailsComputer scienceUser interface

The present invention relates to a device and a method which are used to detect the switching of television programs. The device includes a demodulator, a demultiplexer, a caption decoder, a user interface, a controller and a comparator, wherein, the demodulator receives television program signals, the demultiplexer separates caption signals from audio and video signals, the caption decoder decodes the caption signals and extract stable caption attribute information, the user interface is used for a user to specify a target program, the controller stores the stable caption attributes of the specified target program and activates the comparator to operate, and the comparator analyzes and compares the change of the stable caption attributes and exports prompt signals when the switching of programs is detected. The device of detecting the switching of television programs of the present invention can judge the change of programs by detecting the change of the stable caption attributes, so the device can detect not only the situation that one of two continuous programs has caption attributes, but also the situation that all of the two continuous programs have caption attributes.

Owner:HITACHI LTD

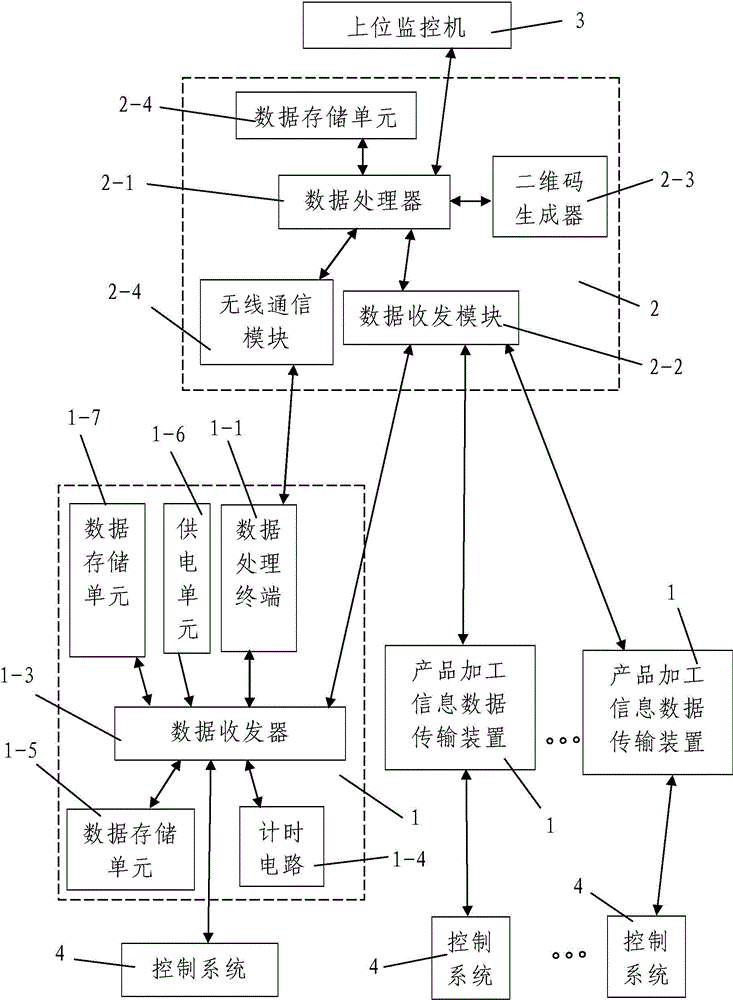

Machinery product processing production line based on numerical control machine tools

The invention discloses a machinery product processing production line based on numerical control machine tools. The machinery product processing production line comprises multiple numerical control machine tools used for sequentially processing processed products one by one respectively, multiple product processing information data transmission devices respectively distributed on the numerical control machine tools, product processing information recorders distributed in a host monitoring room, and a host monitoring machine connected with the product processing information recorders, wherein the product processing information data transmission devices comprise a data processing terminal, a data transceiver and a timing circuit, the data processing terminal is connected with the data transceiver, the data processing terminal is connected with a control system of the distributed numerical control machine tools, and the product processing information recorders comprise a data processor, a data transceiving module, a two-dimensional code generator and a data storage module. The machinery product processing production line is reasonable in design, is simple and convenient to operate, has the good use effect and can automatically record the processing information of each stage of the processed products during product processing in details for later query.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

Novel steel cylinder steel stamp number marking device and method

PendingCN108944101AQuick noteAccurate recordLaser beam welding apparatusStampingSheet steelDrive wheel

The invention relates to the technical field of steel cylinder marking machines, in particular to a novel steel cylinder steel stamp number marking device. The marking device comprises a fed cylinderconveying line, a steel cylinder rotating mechanism and a marking machine, wherein the steel cylinder rotating mechanism is arranged at the position, close to a fed cylinder, of the fed cylinder conveying line, the steel cylinder rotating mechanism comprises a support, a driving wheel arranged on one side of the support and driven through a motor, and a driven wheel arranged on the other side of the support, the marking machine is installed on the support, a pressing air cylinder is arranged at the top of the support, and a pressing head is arranged on a piston rod of the pressing air cylinder. According to the novel steel cylinder steel stamp number marking device, steel cylinder numbers are not pre-impressed on a steel plate of a steel cylinder protective cover, while in the movement process of the conveying line, steel cylinder number marks are formed on the steel cylinder protective cover in a etched or struck mode by means of laser or other methods when the steel cylinder is closeto a detection machine, meanwhile, through the method through which steel cylinder number information is directly transmitted to a computer, the steel cylinder steel stamp numbers are prevented fromrusting and being polluted in the heat treatment and transferring processes, the errors in the processes of photographing, computer recognition and the like are avoided, and the requirements of rapidly and accurately recording the steel cylinder numbers are met.

Owner:天津市长龙宏业燃气设备有限公司

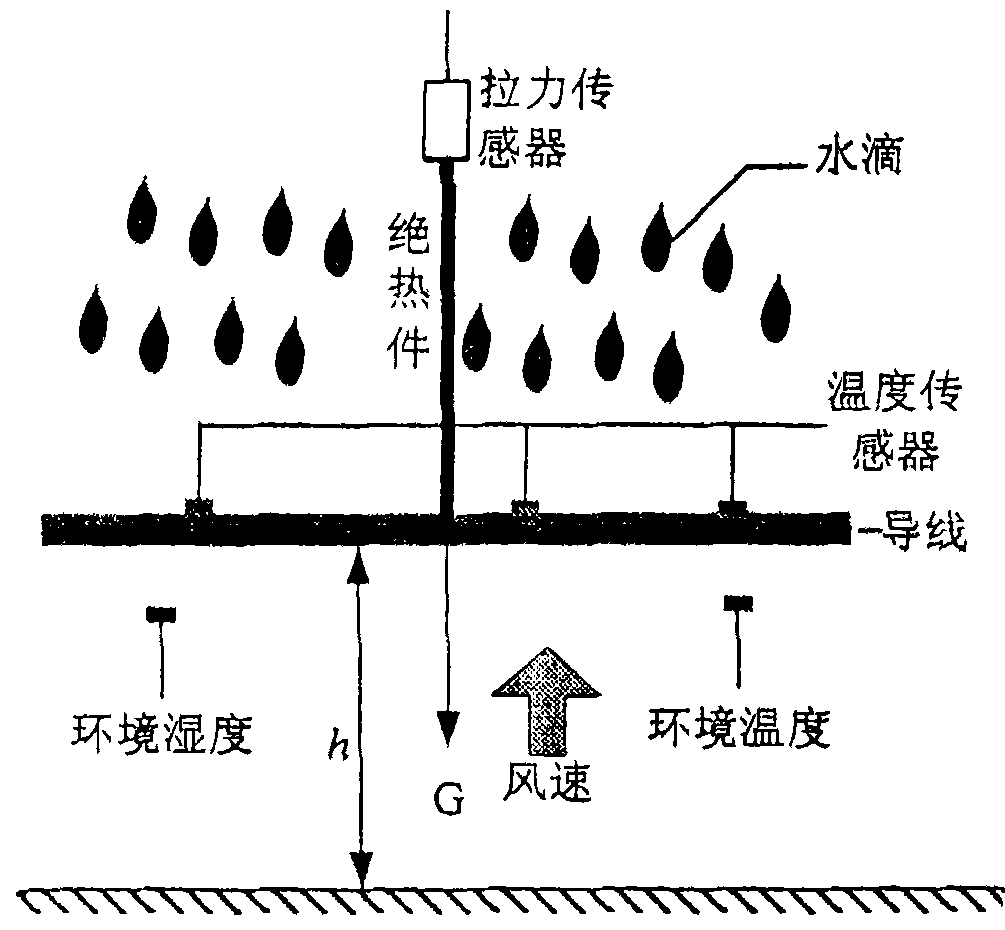

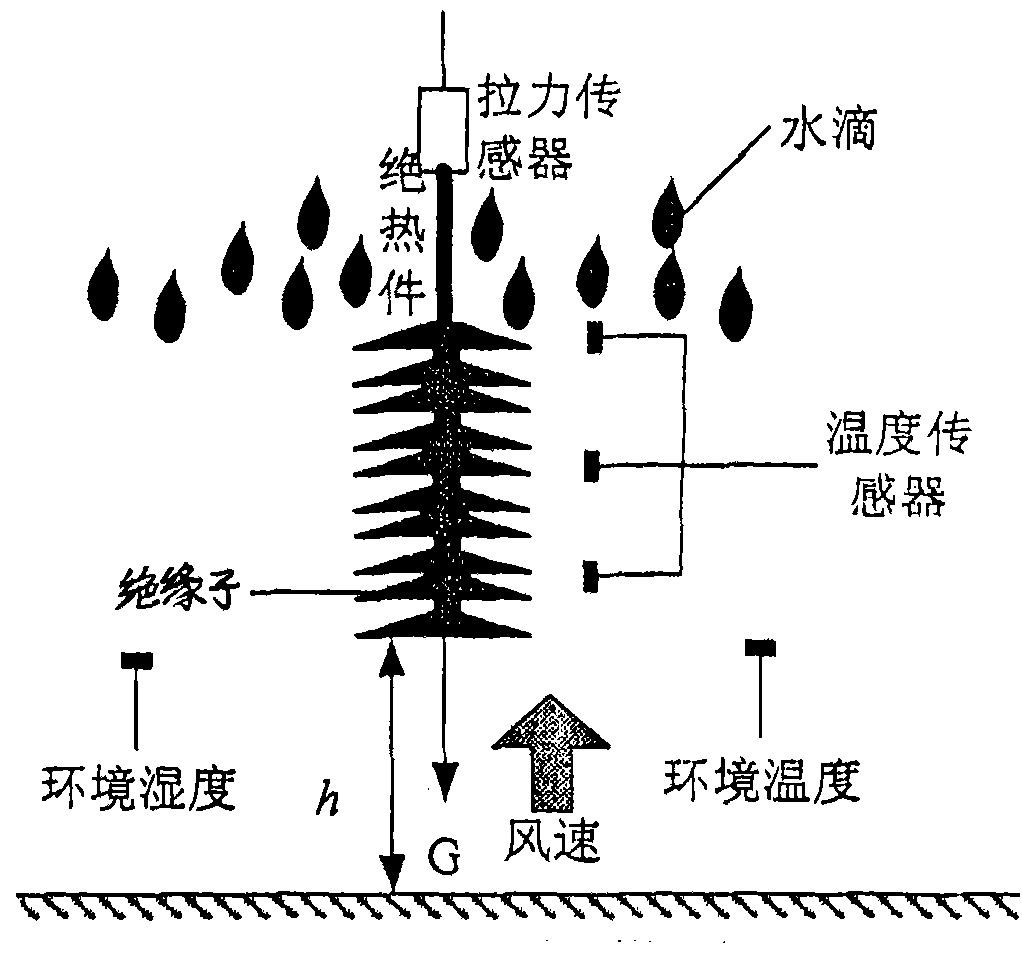

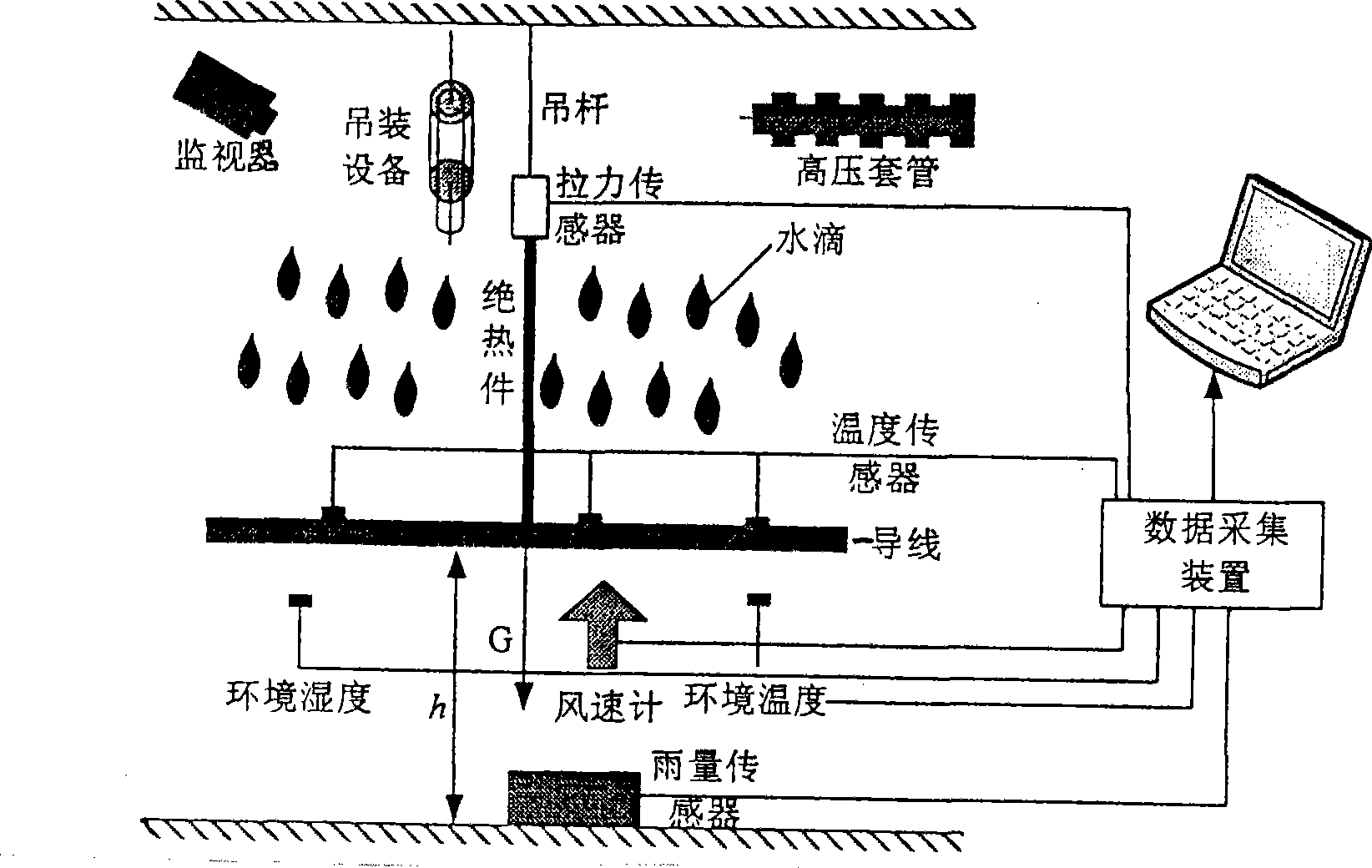

Test method for icing and deicing of transmission line and test system thereof

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

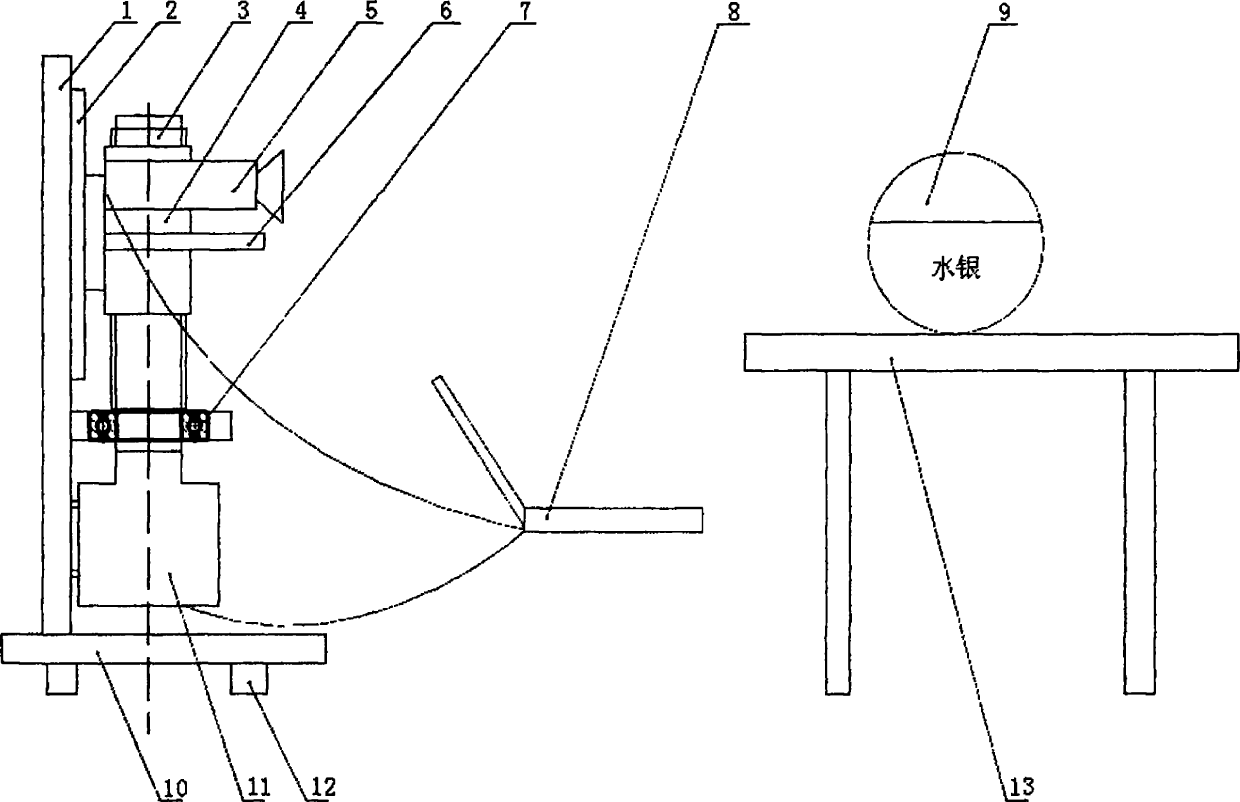

Flatness detecting device based on information fusion technology

The invention discloses a flatness detecting device based on an information fusion technology, belonging to the technical field of measurement. According to the flatness detecting device disclosed by the invention, mercury is injected in a hollow glass ball; a mercury level is used as a reference face in the measurement; and the glass ball and a plane to be detected are in point contact. No matter how the hollow glass ball is placed, the internal mercury level keeps unchanged relatively to the height of a lowest point of the glass ball, so that the mercury level accurately represents the height change on the point on a plane of a working platform. A measuring method disclosed by the invention has less needed hardware; the calculation amount is small; and the precision and the detection efficiency in flatness detection can be improved.

Owner:BEIJING FORESTRY UNIVERSITY

Test method for simulating submarine pipeline movement

PendingCN114088339AEasy to operateImprove efficiencyHydrodynamic testingEducational modelsResearch efficiencyInstrumentation

The invention relates to the field of ocean engineering research, and in particular relates to a test method for simulating submarine pipeline movement. The method comprises the following steps: preparing a soil sample; arranging a seabed; installing a hydraulic loader and injecting water; arranging a monitoring system; starting the hydraulic loader to enable the pipeline to circularly reciprocate, enabling a data acquisition system to record experimental data of each time, recycling a model box and experimental soil after the experiment is finished, and using the obtained experimental data for post-processing. The device provided by the invention can simulate different types of submarine pipeline movement by changing conditions such as pipeline size, movement speed, movement period and the like. The device is convenient to operate, data can be automatically recorded, the scientific research efficiency is improved, and a teaching test instrument is provided for researching the damage effect of the submarine landslide on the pile foundation.

Owner:广州环投南沙环保能源有限公司 +1

Method for eliminating inrush current influence in coordination control of generator set

ActiveCN111740383AGuaranteed stabilityPrevent trippingEmergency protective circuit arrangementsControl engineeringPower grid

The invention belongs to electrical equipment and electrical engineering, relates to the field of generator sets, and particularly relates to a method for eliminating inrush current influence in coordination control of a generator set. When the running transformer generates inrush current and the TA current out-of-limit, the TA current second harmonic content out-of-limit, the TA current negativesequence current out-of-limit, the TV abnormal switching condition and the TA current break variable out-of-limit switching condition are met, the device starts the measurement TA and switches to theprotection TA, so that the stability of coordination control of the generator set is kept, and the generator set power oscillation and the problem of tripping of the generator set in the case of severe power oscillation can be avoided; and the problems that in the case of no-load input of a transformer or instantaneous fault of a power grid, inrush current generated by a running transformer can cause saturation of a measurement-level current transformer for a generator power transmitter, the output can not correctly convert primary actual power, and if the deviation is large and large-amplitude fluctuation occurs, the coordination control of the generator set is unstable, the power of the generator set is oscillated, and the tripping of the generator set is caused in the severe case can besolved.

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

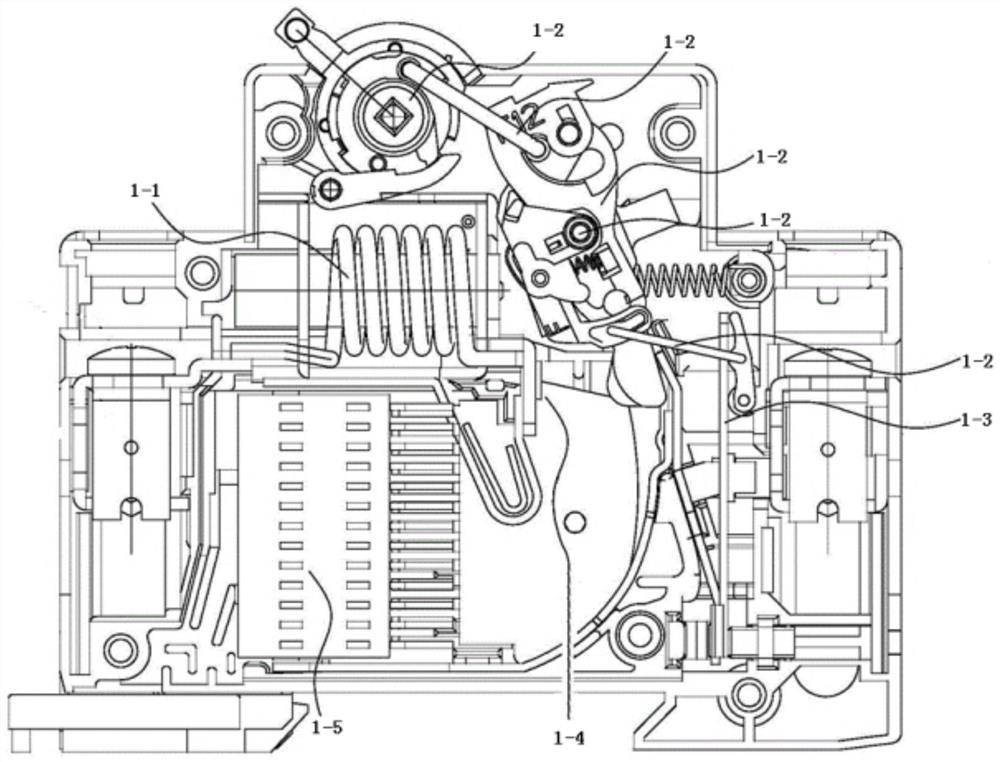

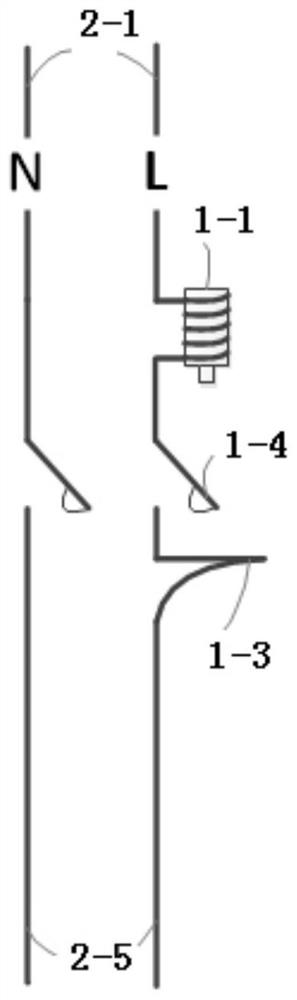

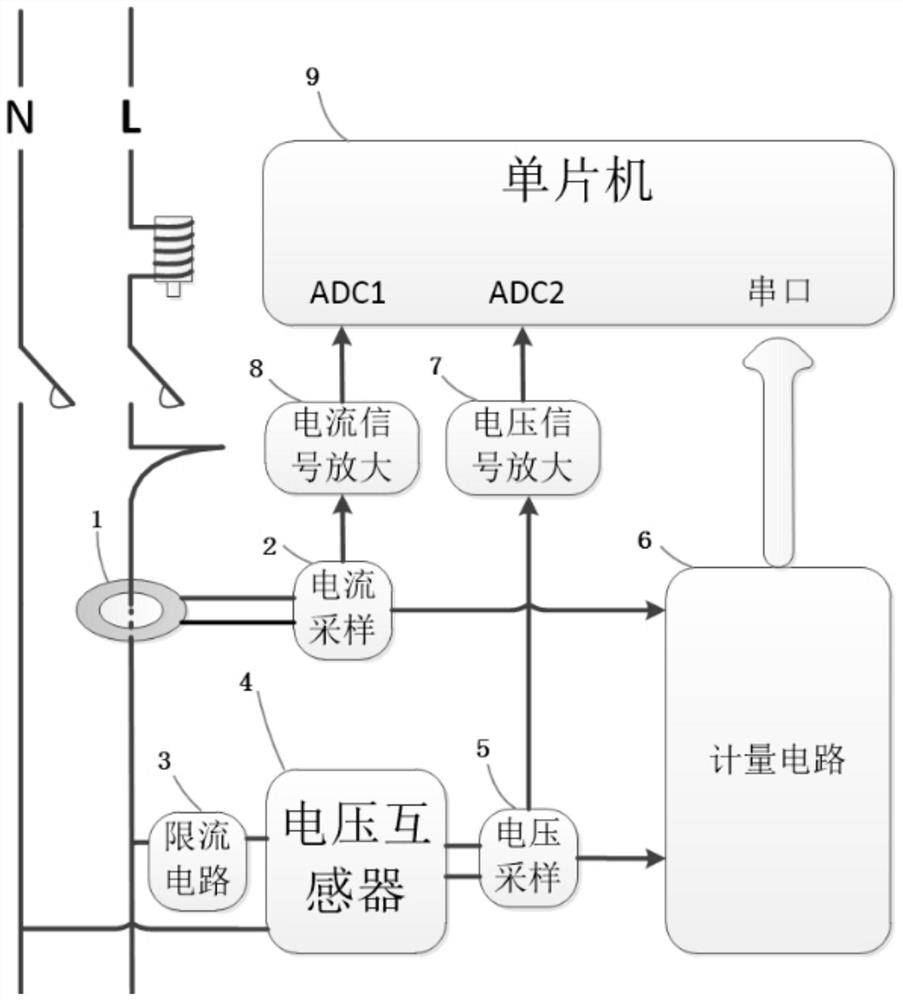

Metering and protecting system and method for intelligent miniature circuit breaker

PendingCN111650413ALow costGood serviceSpecial tariff metersInduction metersOvervoltageElectric power system

The invention discloses a metering and protecting system and method for an intelligent miniature circuit breaker. The metering and protecting system comprises a protection circuit and a metering circuit for the miniature circuit breaker. The protection circuit is used for collecting and integrating data to control the miniature circuit breaker to connect or disconnect a power supply connected withthe miniature circuit breaker. The metering circuit is used for metering voltage, current, frequency, power and electric energy data of a line where the miniature circuit breaker is located. The costof purchasing a large number of electric energy meters by a user is effectively reduced. More safe guarantee is provided, more convenient service is provided, the electric energy metering and billingfunction can be achieved, the electric quantity can be limited, automatic outage of the limited electric quantity is achieved, automatic point sending after money charging is achieved, overvoltage, undervoltage and power limiting protection functions with settable thresholds are provided, fire disasters are prevented, automatic wave recording can be achieved, and the functions of analyzing faultreasons of an electric power system can be achieved.

Owner:江苏三口井信息科技有限公司

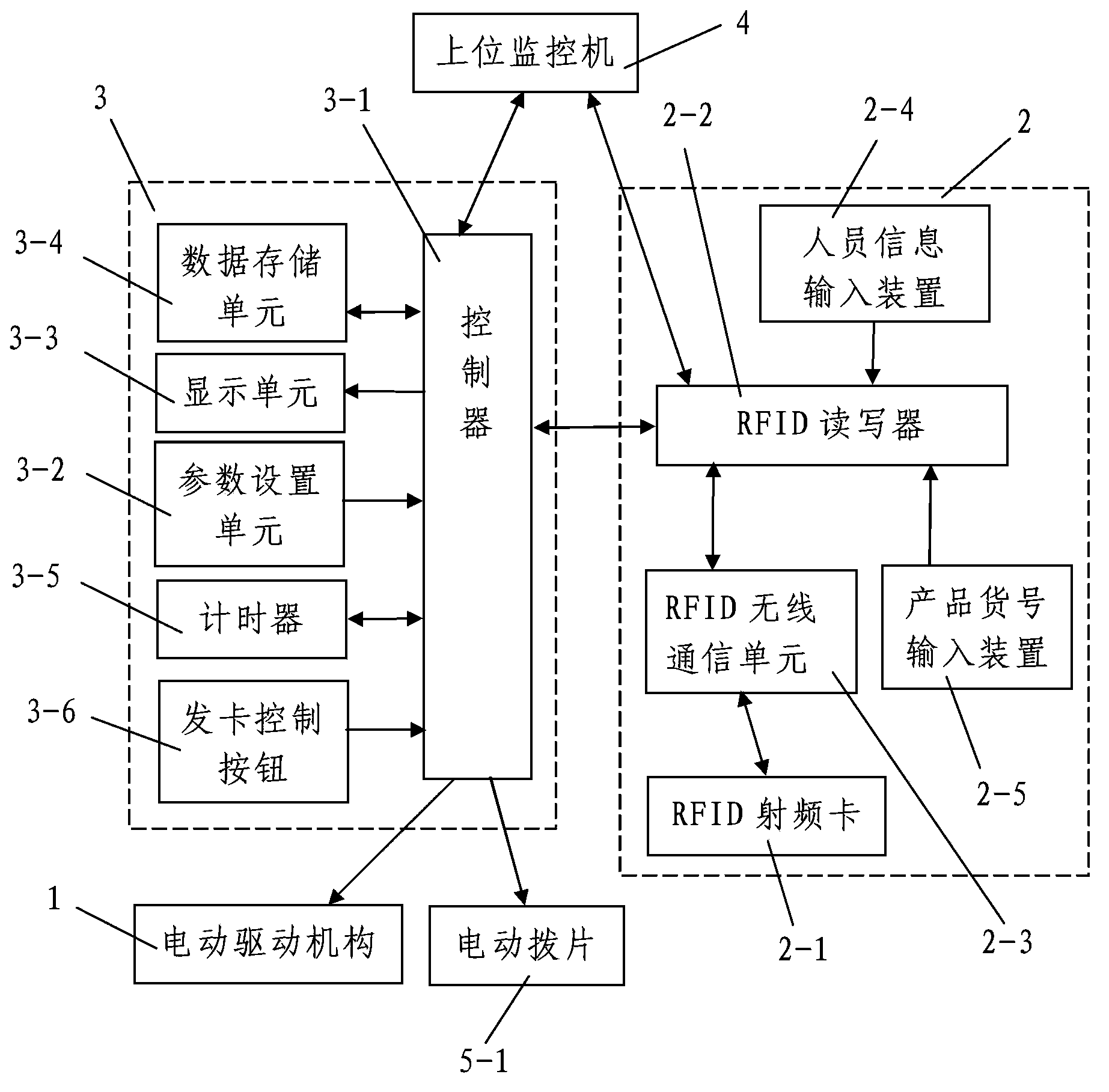

Numerical control machine tool based on RFID radio frequency card

InactiveCN103792878AReasonable designLow costTotal factory controlNumerical controlNumerical controlMotor drive

The invention discloses a numerical control machine tool based on a RFID radio frequency card. The numerical control machine tool comprises a machine tool body, a product fixing mechanism, a motor driving mechanism, and a control mechanism. The motor driving mechanism is in transmission connection with an electric processing cutter through a transmission mechanism. The control system comprises a controller, a parameter setting unit, a display unit, and a data storage unit. The numerical control machine tool further comprises an automatic processing information recording device disposed on the machine tool body. The automatic processing information recording device comprises a RFID radio frequency card, a personnel information input device, a product number input device, and a RFID reader-writer which reads and writes information stored in the RFID radio frequency card. The control system further comprises a timer connected with the controller. The numerical control machine tool based on the RFID radio frequency card further has advantages of reasonable design, high wiring convenience, simple operation, high intelligent degree, high use effect, and a capability of automatically and quickly recording processing information of the processed products in detail in product processing.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

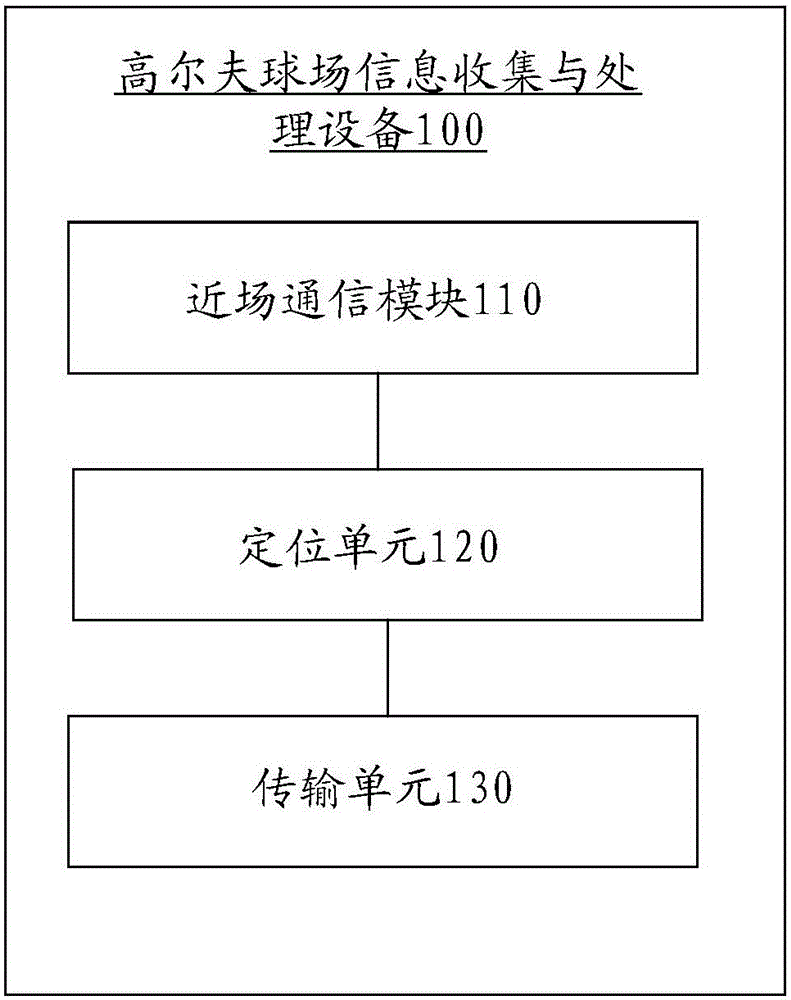

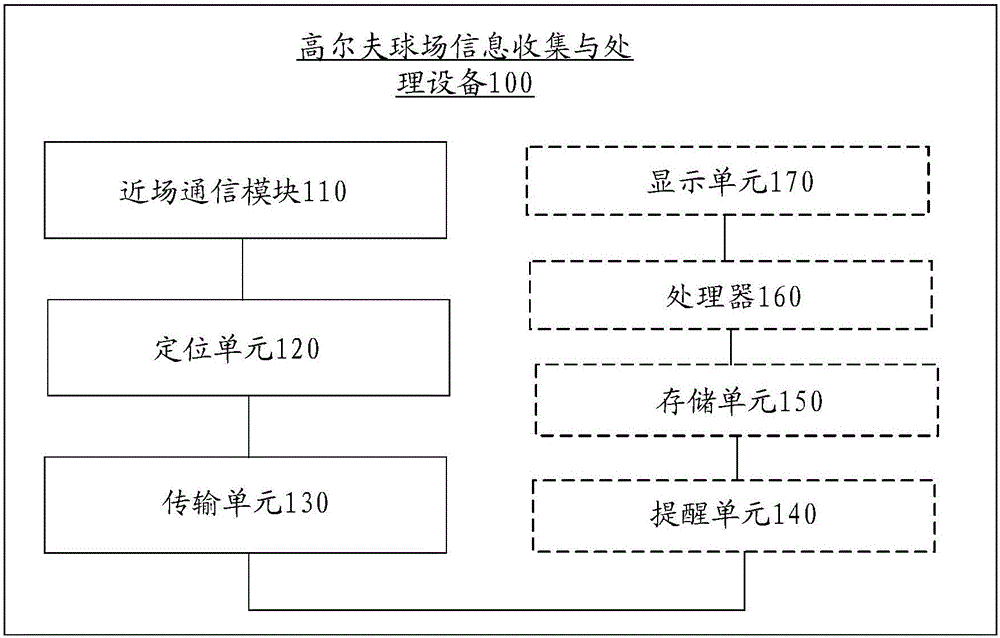

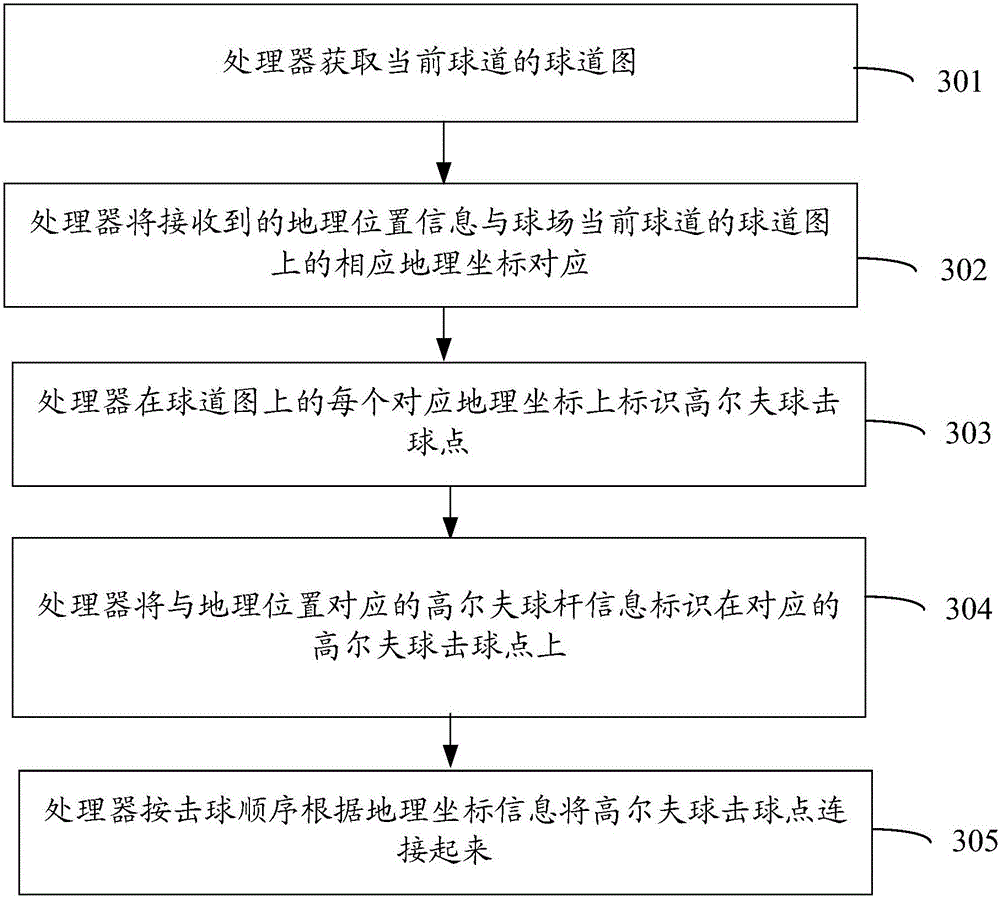

Information gathering and processing equipment, information processing equipment and information processing system

InactiveCN105915254AEnsure continuityAutomatic recordingNear-field transmissionWireless commuication servicesInformation processingGolf course turf

The invention provides golf course information gathering and processing equipment, information processing equipment and an information processing system. The golf course information gathering and processing equipment can be worn by a golfer, and the information gathering equipment comprises a near-field communication module, a positioning unit and a transmission unit, wherein the near-field communication module is configured to acquire an electronic tag on a golf club for striking a golf every time to acquire golf club information; the positioning unit is configured to acquire geographic position information during striking, wherein the geographic position information is within a first predetermined range at the position of the golf; and the transmission unit is configured to transmit the acquired golf club information and geographic position information. The golf course information gathering and processing equipment can efficiently and accurately record each striking situation, thereby ensuring the striking consistency of the golfer.

Owner:BEIJING VOOGOLF TECH CO LTD

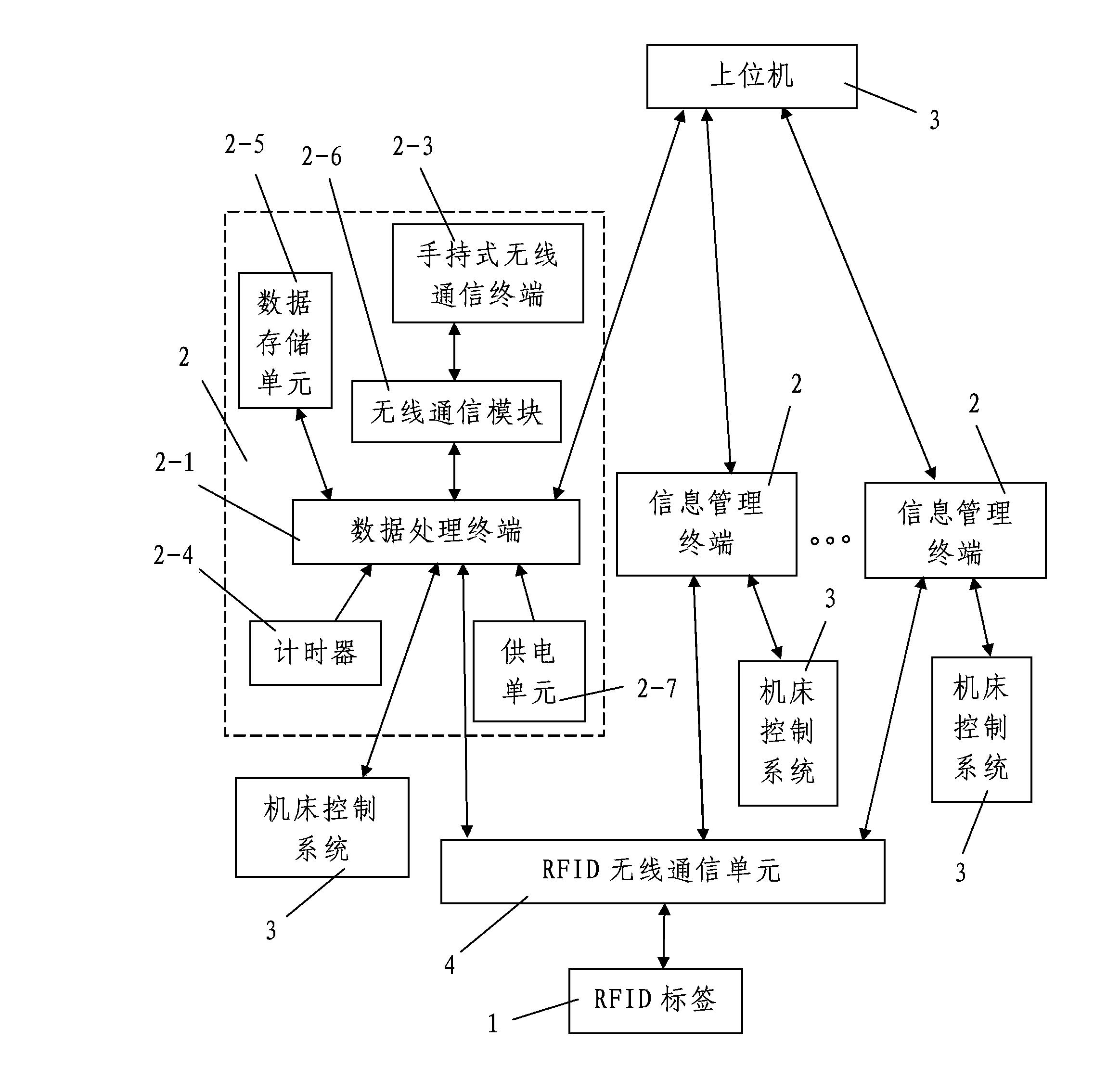

Machining production line

InactiveCN103792882AReasonable designLow costNumerical controlProduct processingMachine tool control

The invention discloses a machining production line comprising a plurality of numerical control machine tools for successively machining products to be machined, a plurality of information management terminals used in cooperation with the plurality of numerical control machine tools, and a host computer arranged in a host management room, wherein the plurality of information management terminals are in one-to-one correspondence with the plurality of numerical control machine tools. Each information management terminal comprises a power supply unit, a data processing terminal operated by machine tool operators, and an RFID reader for reading and writing information stored in RFID tags pasted on products being machined currently. Each data processing terminal is connected with a machine tool control system of a numerical control machine tool corresponding to the data processing terminal. The machining production line is reasonable in design, convenient in wire connection, easy to operate, high in intelligent degree, good in use effect, and capable of not only recording machining information of products to be machined automatically, rapidly and in detail during product machining, but also being beneficial for machining workers in a next machining step to knowing accurate machining information of previous machining steps in detail.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

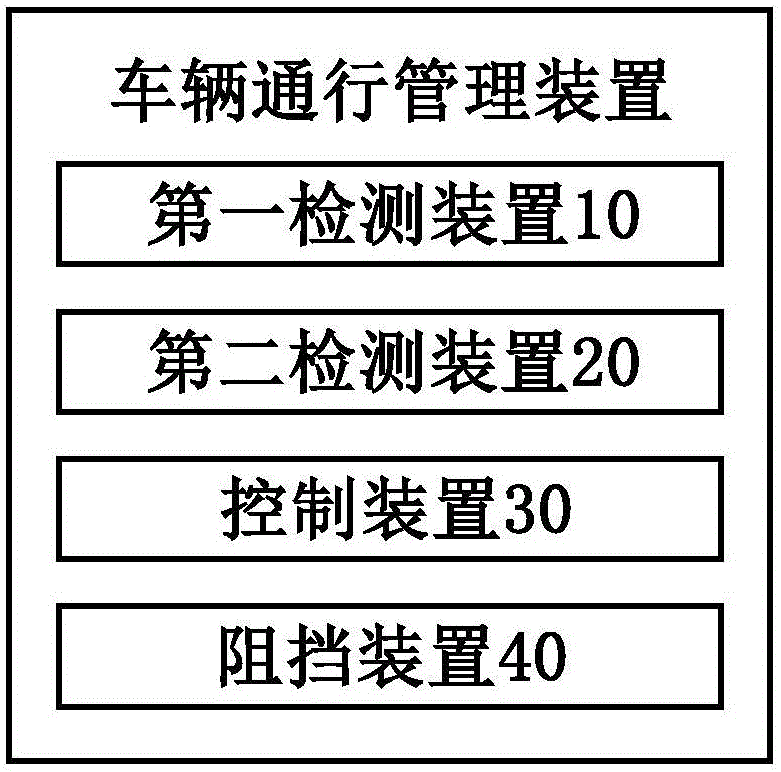

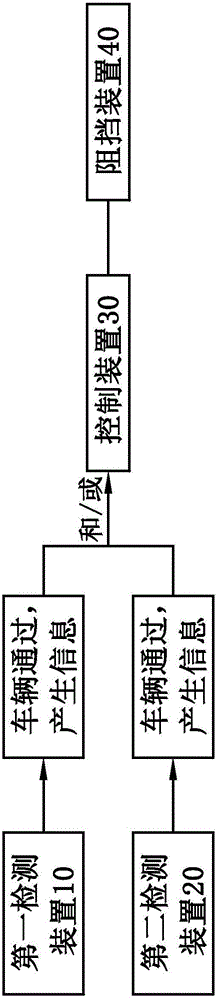

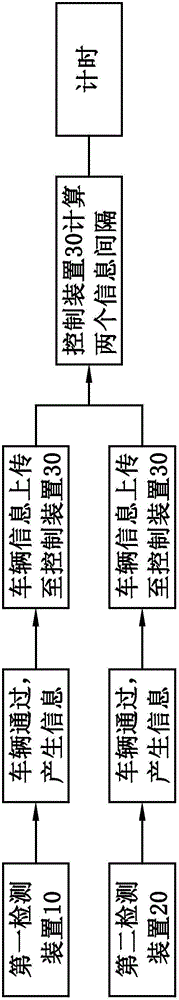

Vehicle passing management apparatus and management method thereof

Owner:腾石智能科技(上海)有限公司

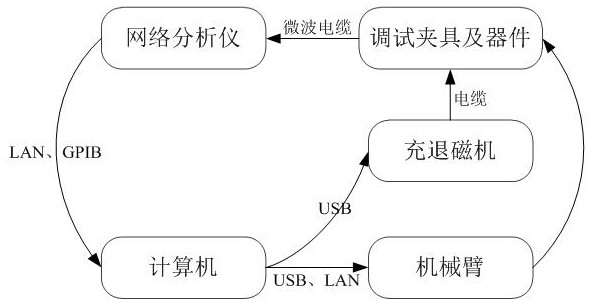

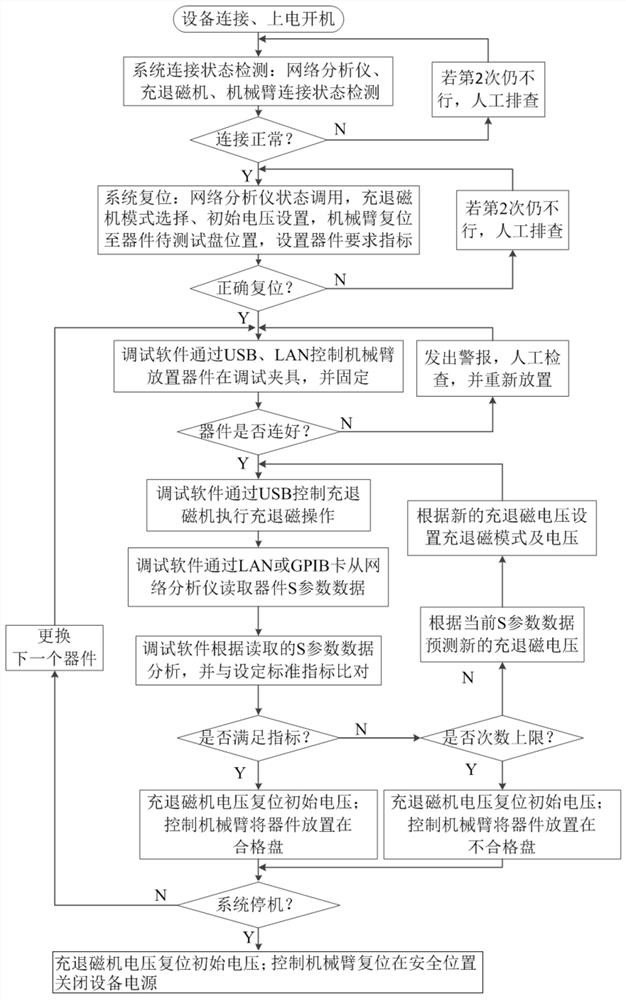

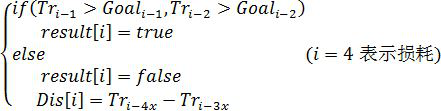

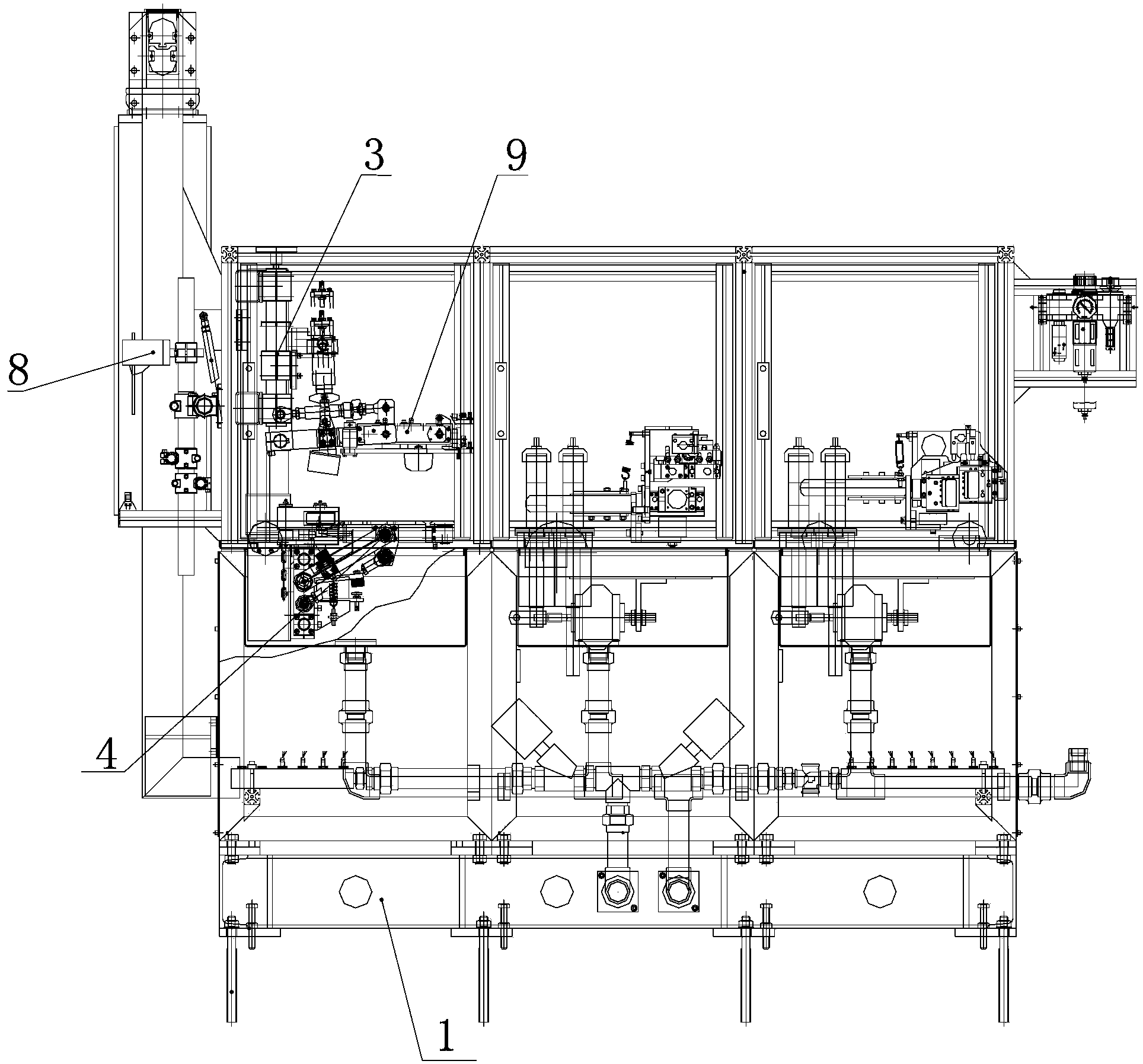

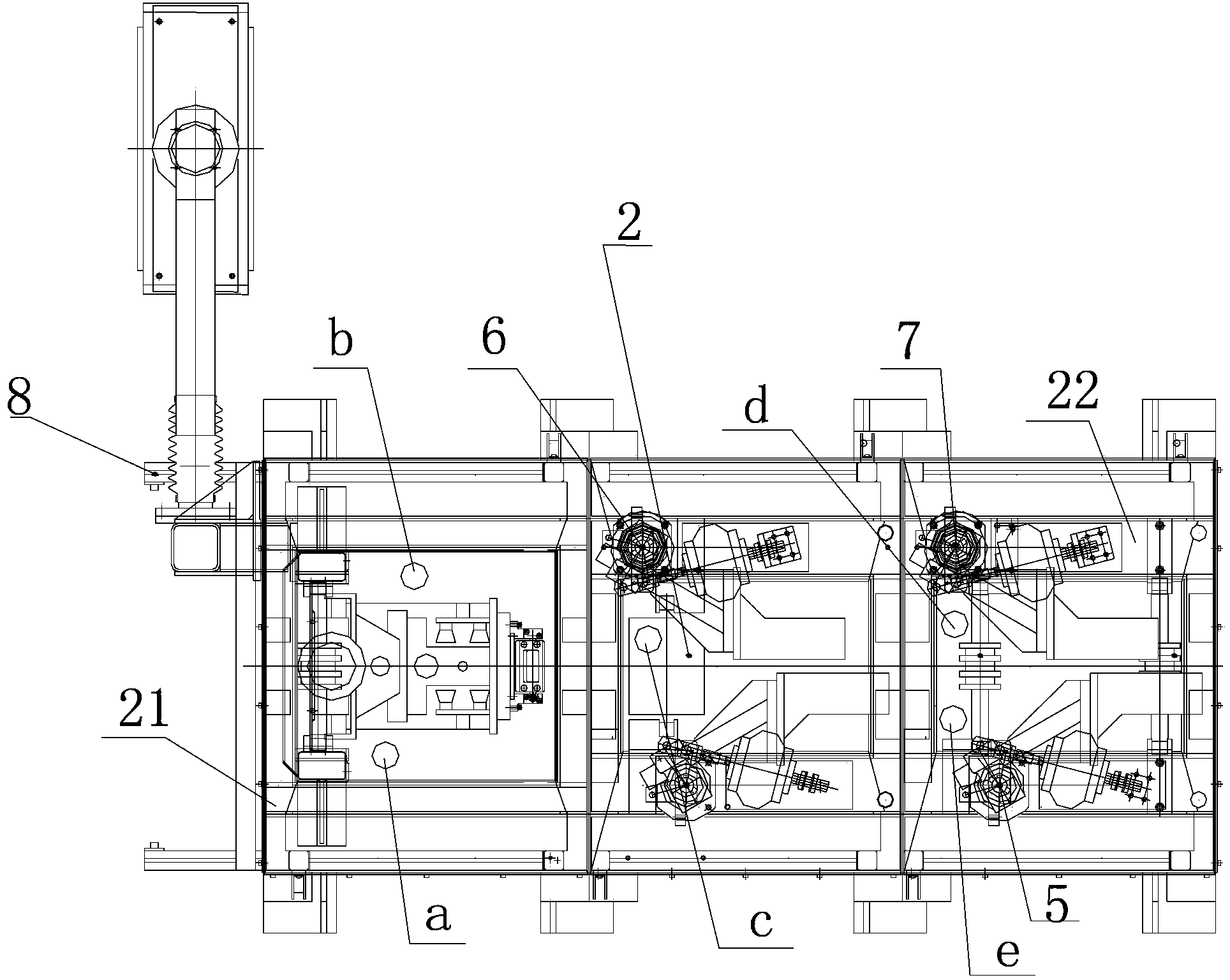

Automatic rapid magnetic field debugging method suitable for lumped parameter surface-mounted circulator

ActiveCN111816966ARealize automatic debugging of magnetic fieldImprove efficiencyWaveguide type devicesData controlControl system

The invention discloses an automatic rapid magnetic field debugging method suitable for lumped parameter surface-mounted circulator. The method comprises the steps: (1) constructing a control system used for debugging a device to be debugged, wherein the control system comprises a computer, a network analyzer connected with the computer, a mechanical arm, a magnetizing and demagnetizing machine, adebugging clamp and three placing positions, the placing positions corresponding to a device disc to be debugged, a qualified device disc and an unqualified device disc respectively; (2) starting thecontrol system for detection; (3) resetting the control system, and setting the magnetizing and demagnetizing machine to be in a demagnetizing mode, and making the mechanical arm reset to the position of the device disc to be debugged; (4) controlling the mechanical arm to take out a to-be-debugged device, installing the to-be-debugged device on the debugging clamp, and obtaining S parameter dataof the to-be-debugged device through the network analyzer; (5) controlling the magnetizing and demagnetizing machine to automatically adjust the voltage to adjust the magnetic field of the product; (6) judging whether the product is qualified or not; (7) carrying out sorting. Automatic debugging of the magnetic field of the device can be realized, the efficiency is greatly improved, and the production is more efficient and stable.

Owner:中国电子科技集团公司第九研究所

Steel rail ultrasonic on-line detection system and control method thereof

ActiveCN102818848BWide detection rangeMultiple track typesAnalysing solids using sonic/ultrasonic/infrasonic wavesMechanical engineeringUltrasonic detection

The invention provides a rail ultrasonic on-line detection system and its control method. The equipment includes a bracket, a roller table, a rail head tread landing gear, a rail bottom landing gear, a rail head right landing gear, a rail head left landing gear, and a rail waist Left landing gear, ultrasonic probe, No. 1 through-beam photoelectric, No. 2 through-beam photoelectric, No. 3 through-beam photoelectric, No. 4 through-beam photoelectric, rail position detection device, rail shape detection device, controller and ultrasonic detector; When the through-beam photoelectric senses the rail, the controller controls the corresponding landing gear to move up and down, thereby driving the ultrasonic probe installed on the landing gear to realize the flaw detection of each part of the rail. When a defect is detected inside the rail, the rail position detection The device outputs the specific position of the defect on the rail, and stops the flaw detection. It has the outstanding advantages of wide detection range, fast detection speed and high detection accuracy.

Owner:四川曜诚无损检测技术有限公司

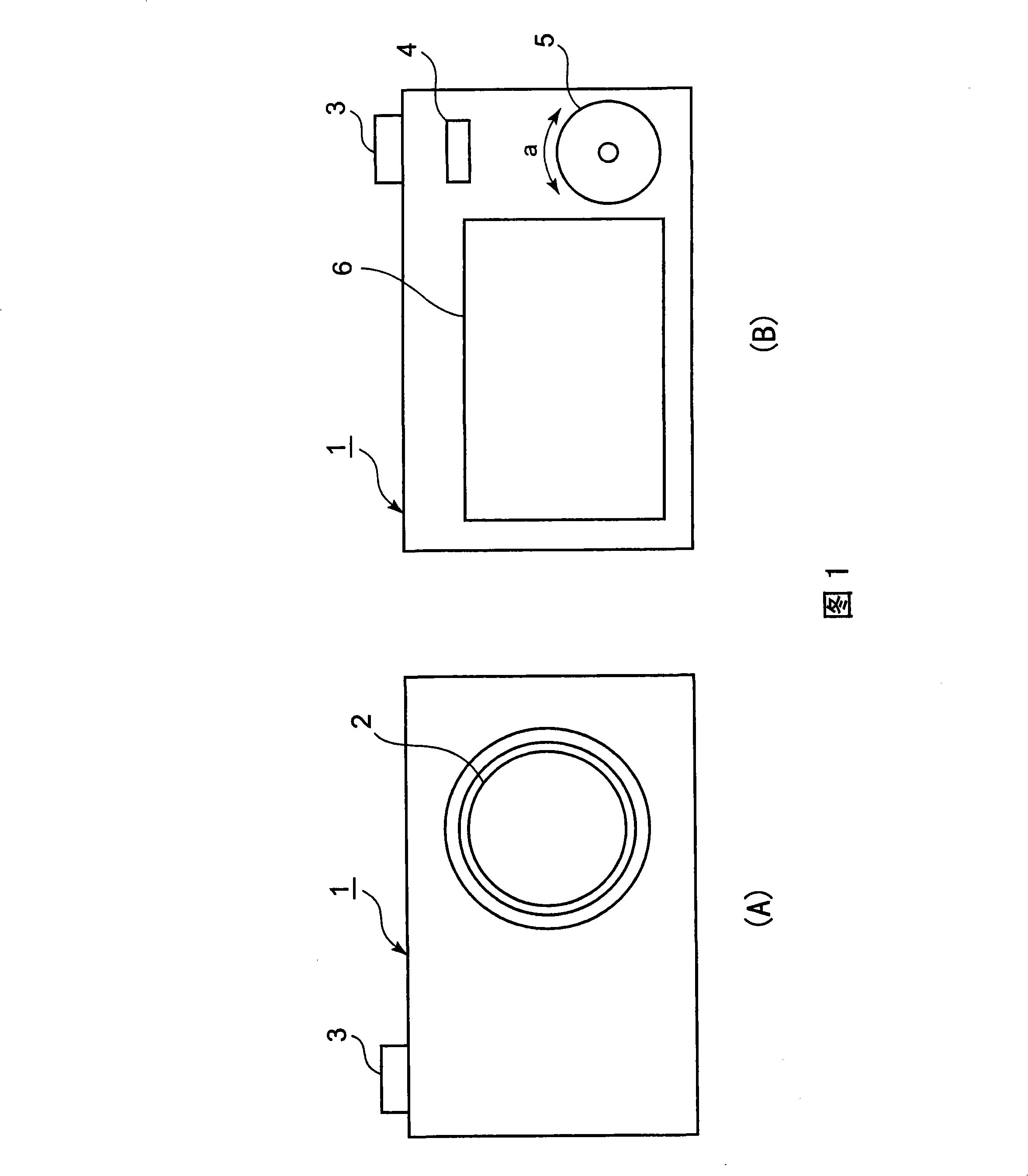

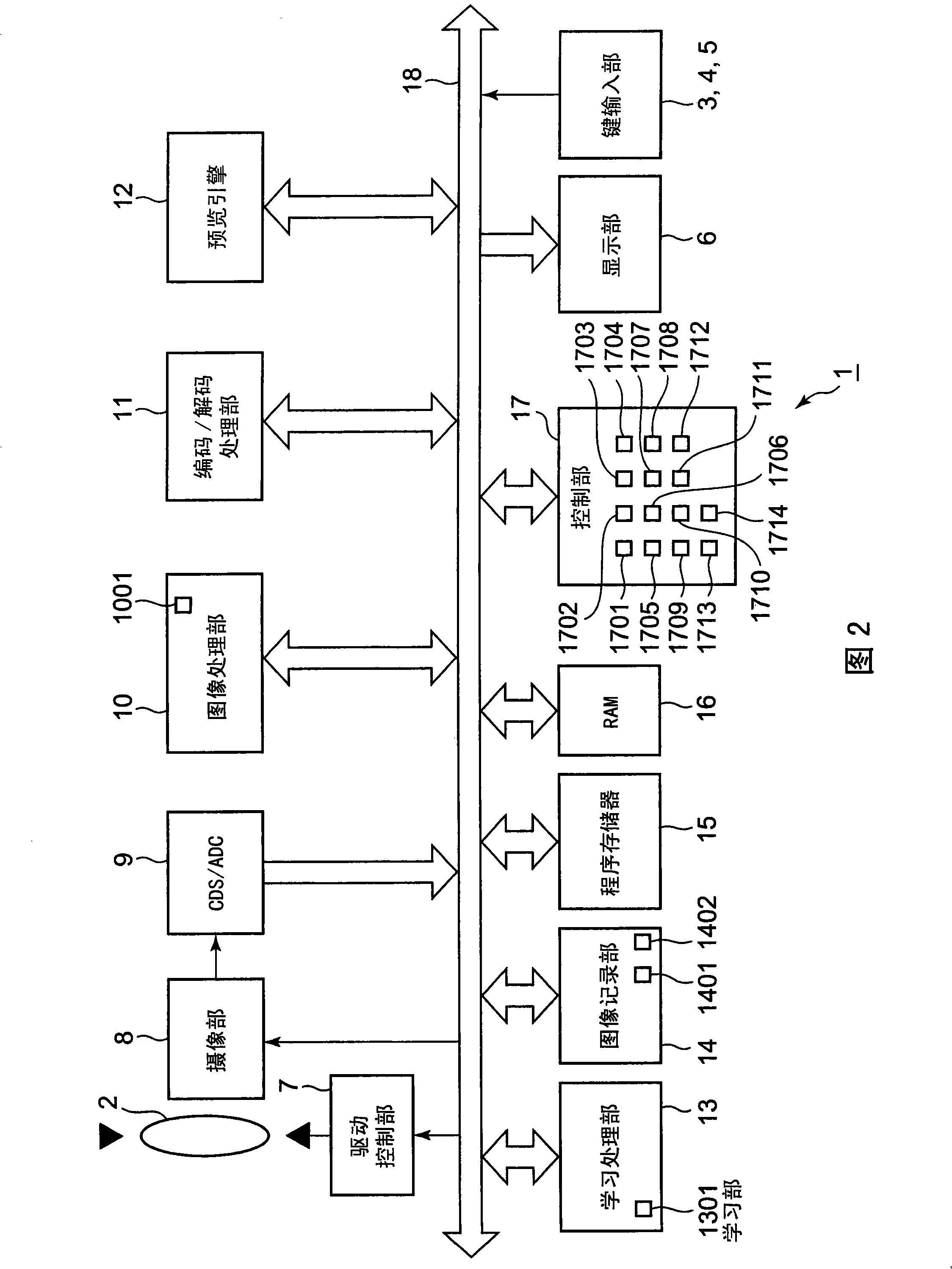

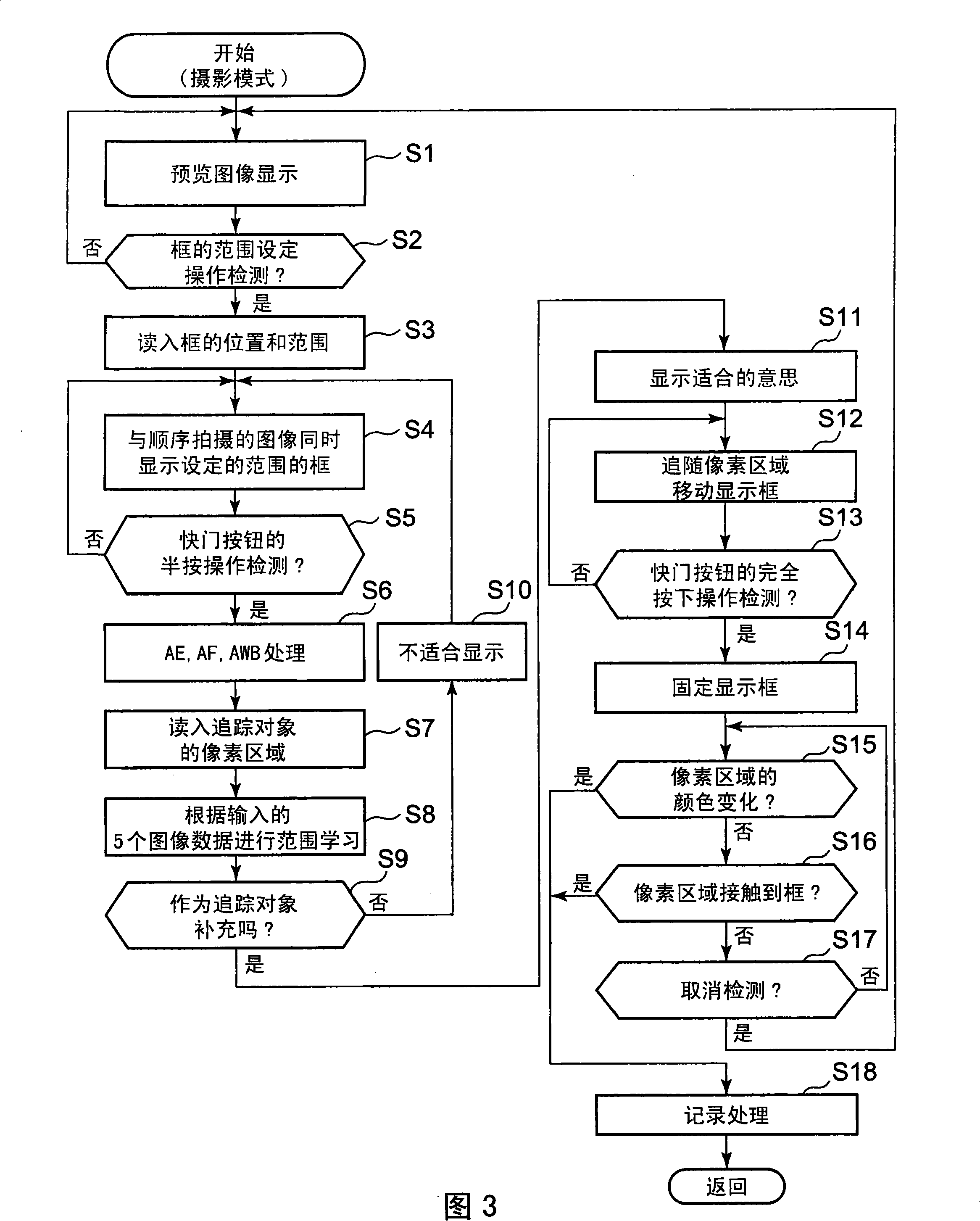

Image capture device that records image accordant with predetermined condition and program

An image capture device (1) sets a central vicinity of a frame (606) of a predetermined area as a focus region upon detecting a half-press operation of a shutter button (3) in a through-the-lens image displaying, designates a central vicinity pixel region of the region as a pixel region (608) to be tracked, and determines whether or not the designated pixel region is adequate as an object of tracking. If the pixel region is adequate, the pixel region is tracked until the shutter button is detected as pressed down fully. When a fully-press operation of the shutter button is detected, the frame of a predetermined area is displayed in a fixed manner on a display unit (6). Upon a detection that a change of the pixel region has occurred, or the pixel region has contacted or exceeded the frame of a predetermined area, a recording processing is started immediately by a high speed consecutive capture.

Owner:CASIO COMPUTER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com