Flatness detecting device based on information fusion technology

A flatness detection and technology technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of poor accuracy, inability to meet the rapid detection of industrial production, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

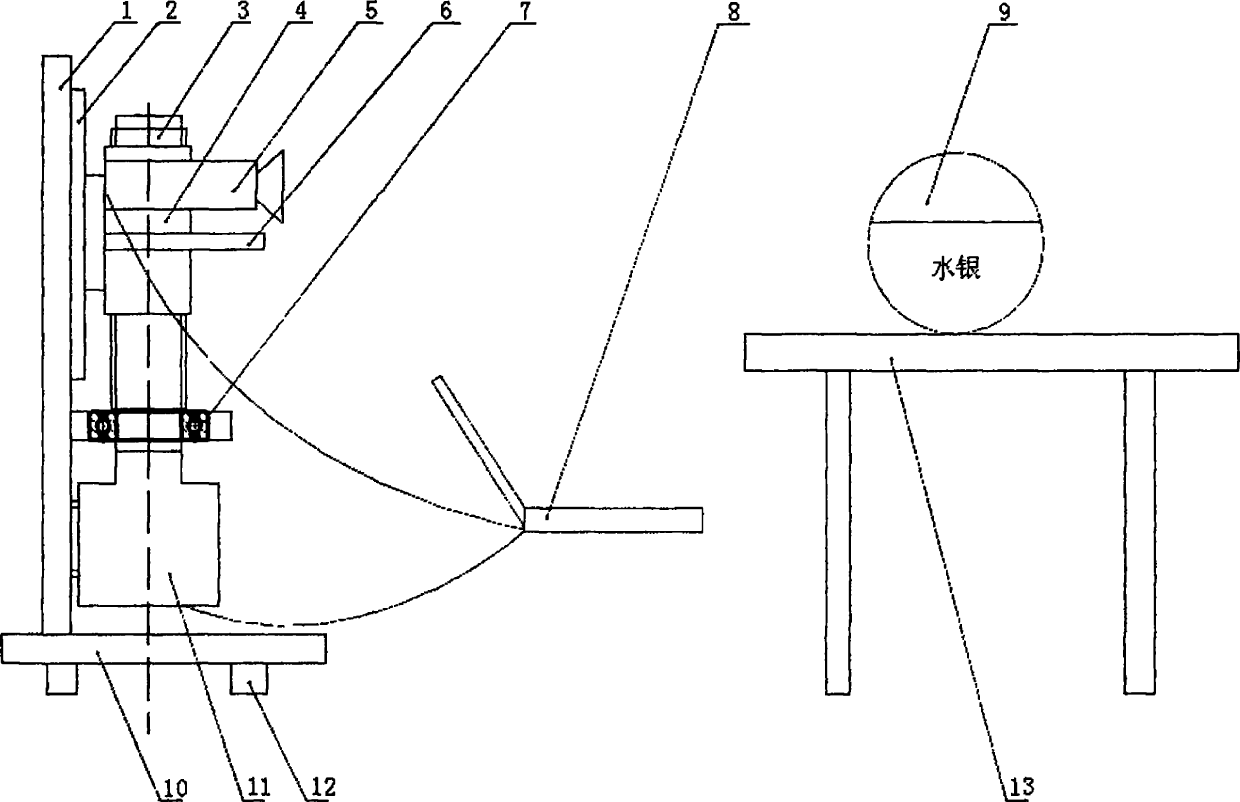

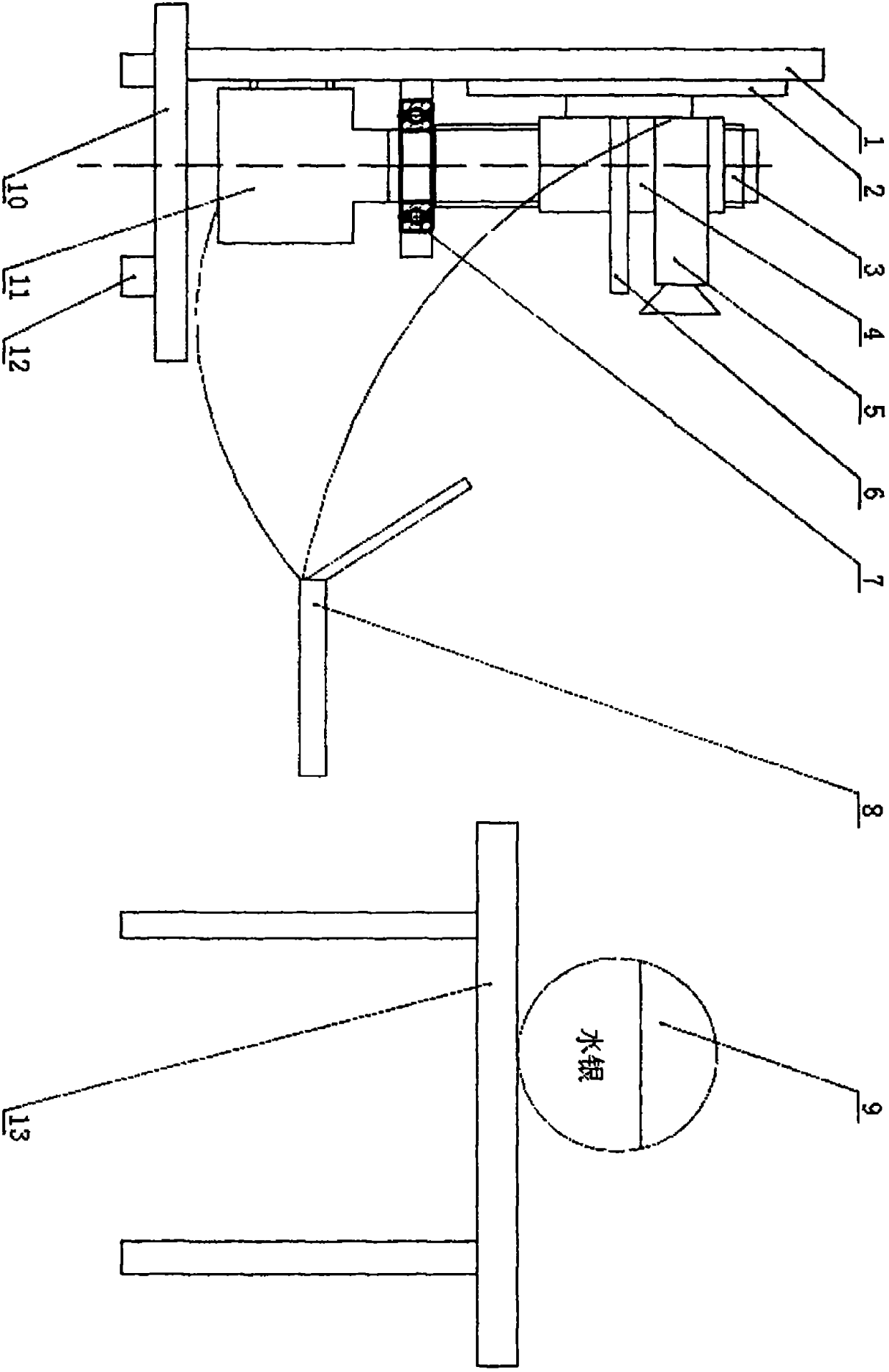

[0006] The laser emitter (6) that device of the present invention adopts is an inline laser emitter, and is fixed with nut (4), and CCD camera (5) is also fixed on the nut (4) parallel with laser emitter (6), The nut (4) can move up and down along the guide rail (2) on the column (1), the screw (3) passes through the bearing (7) and is connected axially with the servo motor (11), and the bearing (7) is fixed on the column (1 ), the column (1) is perpendicular to the base (10) and fixed together, the base (10) is equipped with anchor screws (12), and the height of the anchor screws (12) is adjusted at the beginning of the measurement so that the laser transmitter ( 6) Keep the laser beam emitted horizontally.

[0007] Mercury is housed in the hollow glass sphere (9), and the horizontal plane of the mercury is used as a reference plane, and the hollow glass sphere is placed on the measured plane (13). Regardless of how the hollow glass sphere is placed, the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com