Automatic rapid magnetic field debugging method suitable for lumped parameter surface-mounted circulator

A technology of lumped parameters and debugging methods, applied to waveguide devices, electrical components, circuits, etc., can solve problems such as devices not reaching the best state, complicated operation, poor consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

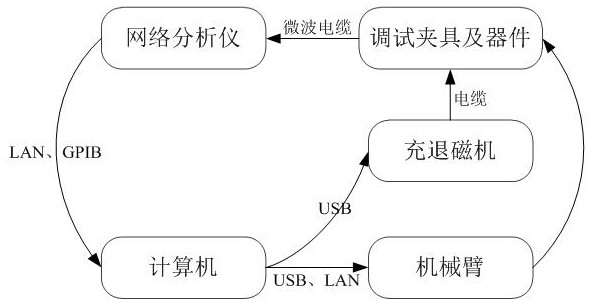

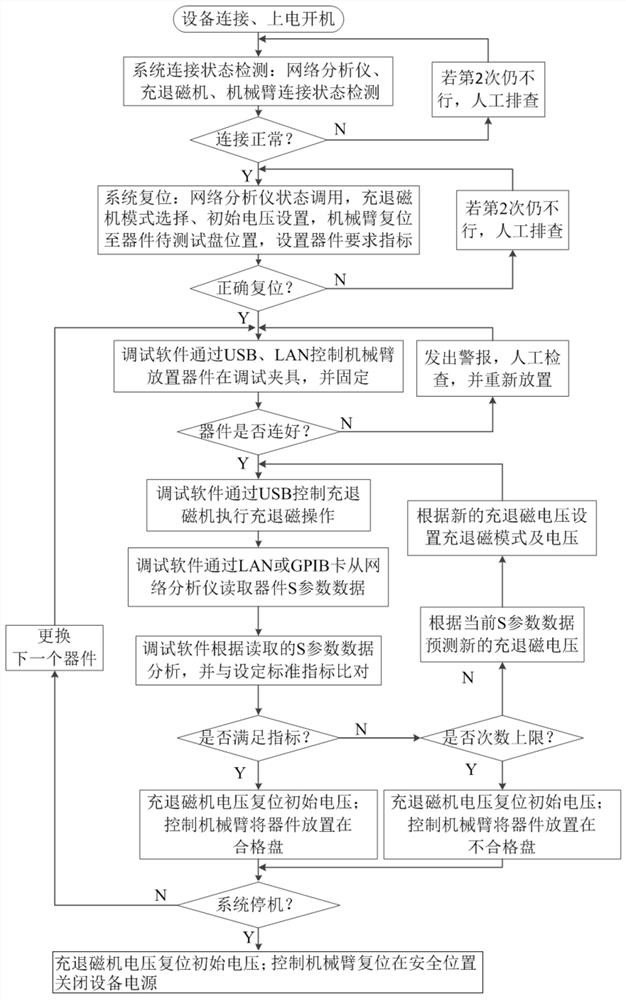

[0041] Embodiment 1: see figure 1 and figure 2 , an automatic and rapid debugging method suitable for the magnetic field of a surface-mounted circulator with lumped parameters, comprising the following steps:

[0042] (1) Build a control system for debugging the device to be debugged. The device to be debugged is a lumped parameter surface mount circulator. The control system includes a computer, a network analyzer, a mechanical arm, a charging and demagnetizing machine, a debugging fixture, And three placement positions, in which the network analyzer, the manipulator and the charging and demagnetizing machine are all connected to the computer;

[0043] The network analyzer is used to obtain the S parameter data of the device to be debugged and send it to the computer;

[0044] The mechanical arm is used to move the device to be debugged according to the control of the computer;

[0045] The charging and demagnetizing machine is used to generate different charging and dema...

Embodiment 2

[0061] Example 2: see figure 1 , this embodiment is further improved on the basis of Embodiment 1. After the step (4) obtains the S parameter data of the initial state of the device to be debugged, it also includes: judging whether the device to be debugged is connected to the debugging fixture normally according to the S parameter data , if it is not normal, reinstall the device to be debugged after manual inspection, and reacquire the S parameter data of the initial state until the connection is normal.

[0062] It also includes step (7) judging whether the control system needs to be shut down;

[0063] If shutdown is required, the charging and demagnetizing machine is reset to the initial voltage, the mechanical arm is controlled to a safe position, and the power is turned off;

[0064] If the system does not need to be shut down, repeat steps (4)-(6) to debug the next device to be debugged.

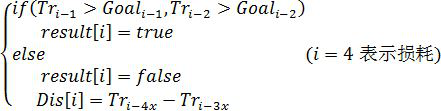

[0065] In the present invention, for the judgment of whether the performance in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com