Full-automatic bearing grease evening machine

A fully automatic, bearing technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of single grease uniformity, high labor intensity, operator fatigue, etc., to achieve uniform grease uniformity, ensure consistency, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

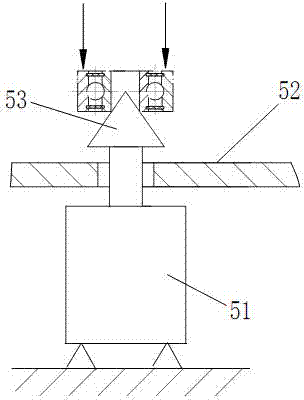

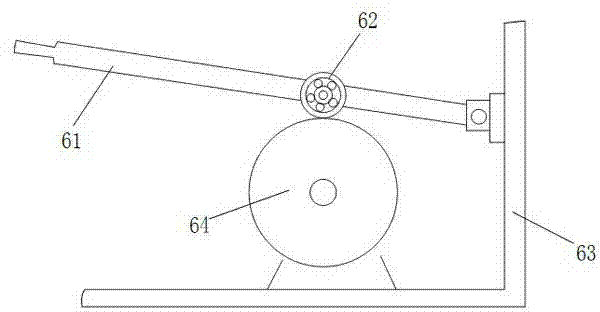

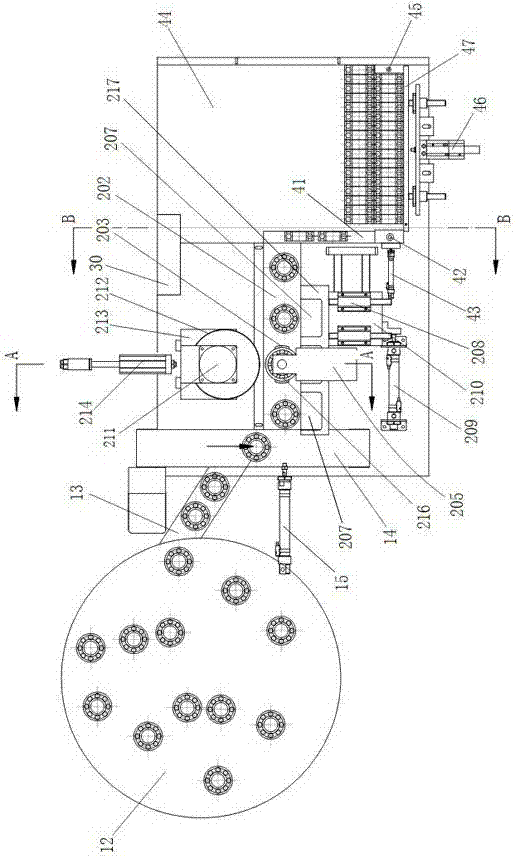

[0037] refer to Figure 3-5 : full-automatic bearing grease homogeneous machine, including feeding mechanism, grease homogenizing mechanism and alignment mechanism connected in sequence, the feeding mechanism includes the first workbench 11, the rotary drum 12 positioned on the first workbench 11, and the connection between the rotary drum 12 The conveyor belt 14 connected to the output port 13, the first material pushing cylinder 15 located on one side of the conveyor belt 14, the bearing to be greased is placed in the rotary bucket 13, and the rotary bucket 13 rotates in one direction, clockwise in this embodiment Rotate in one direction, send the bearings to the conveying belt 14 in a single row through the output port 13, when the conveying belt 14 conveys the bearings to the corresponding first pushing cylinder 15, the first pushing cylinder 15 pushes the bearings into the position on the conveying belt 14 In the fat uniform channel 202 of the fat uniform mechanism on the...

Embodiment 2

[0052] The difference between this embodiment and the first embodiment lies in that: the entire row of worktables 43 is arranged obliquely, and the inclination angle and direction of the whole row of worktables 43 are consistent with the inclination angle and direction of the blanking channel 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com