Novel steel cylinder steel stamp number marking device and method

A marking method and technology for steel cylinders, applied in printing, laser welding equipment, stamping, etc., can solve problems such as large error rate, influence of cylinder number recognition rate, detection data that cannot correspond to cylinder number, etc., and achieve the effect of automatic recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

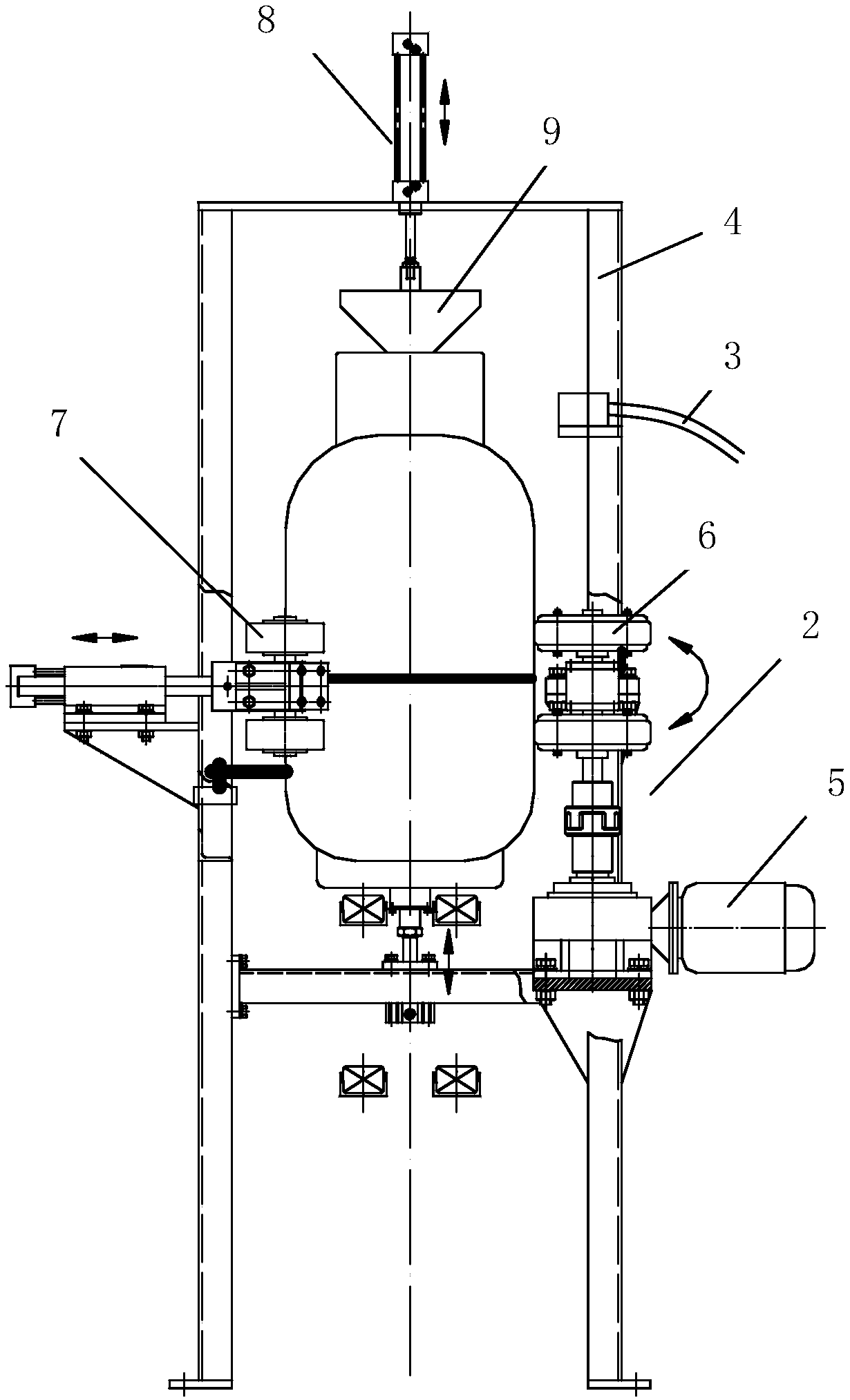

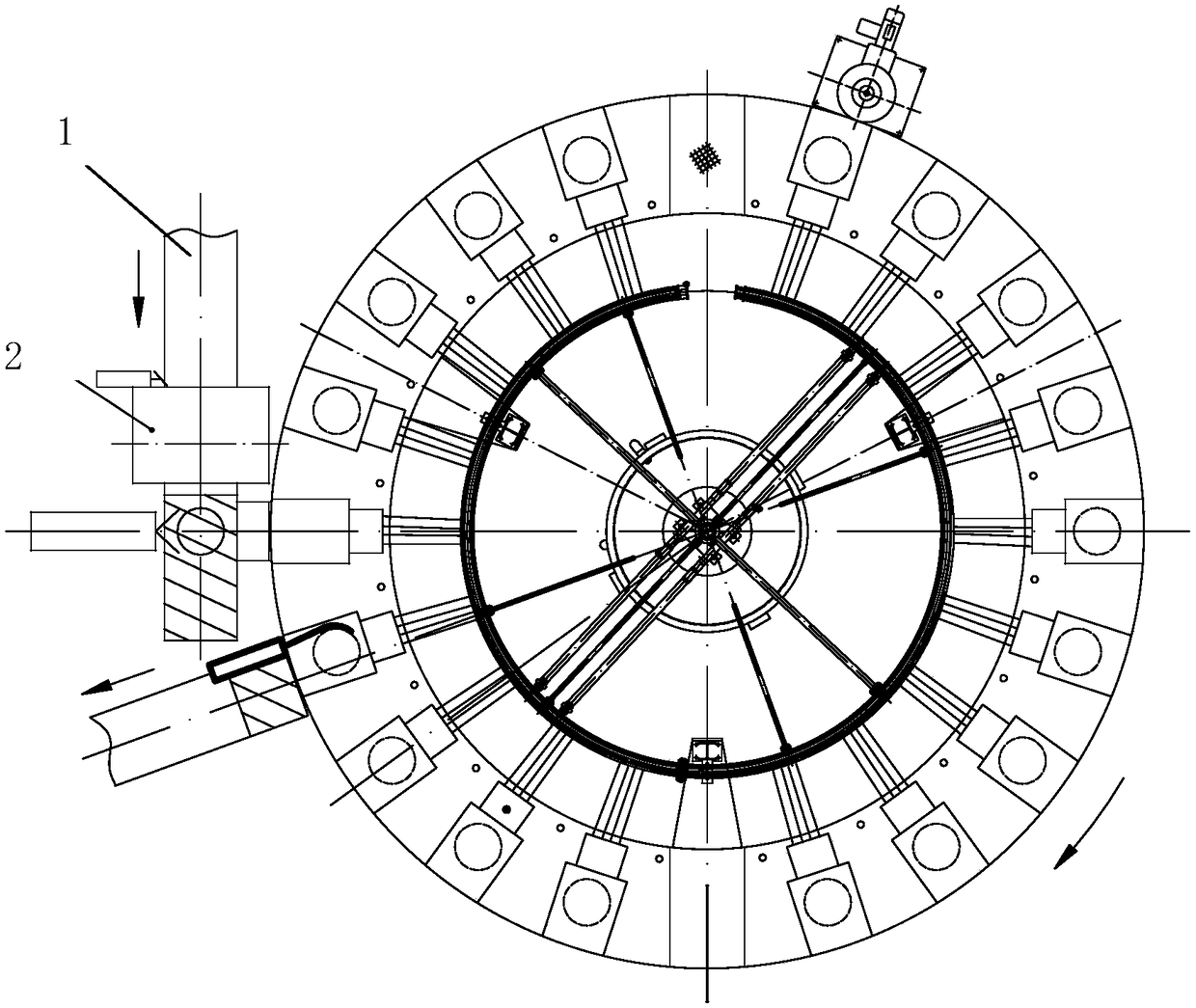

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a new steel cylinder stamp number marking device and method, including a bottle loading conveying line 1, a steel cylinder rotating mechanism 2 and a marking machine 3; the steel cylinder rotating mechanism is installed on the bottle conveying line close to the bottle , the steel cylinder rotation mechanism includes a support 4, a driving wheel 6 arranged on one side of the support and driven by a motor 5, and a driven wheel 7 arranged on the other side of the support. The driven wheels are two groups, which are driven by the cylinder to move left and right. The cylinder is clamped between the wheels. After the cylinder is clamped by the driving wheel and the driven wheel, the cylinder is driven by the motor to rotate. The purpose is to find the opening position of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com