Six-axis industrial robot track accurate tracking-and-controlling oriented intelligent teaching system

An industrial robot, tracking control technology, applied in the field of robotics, to achieve the effect of reduced volume, high control precision and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

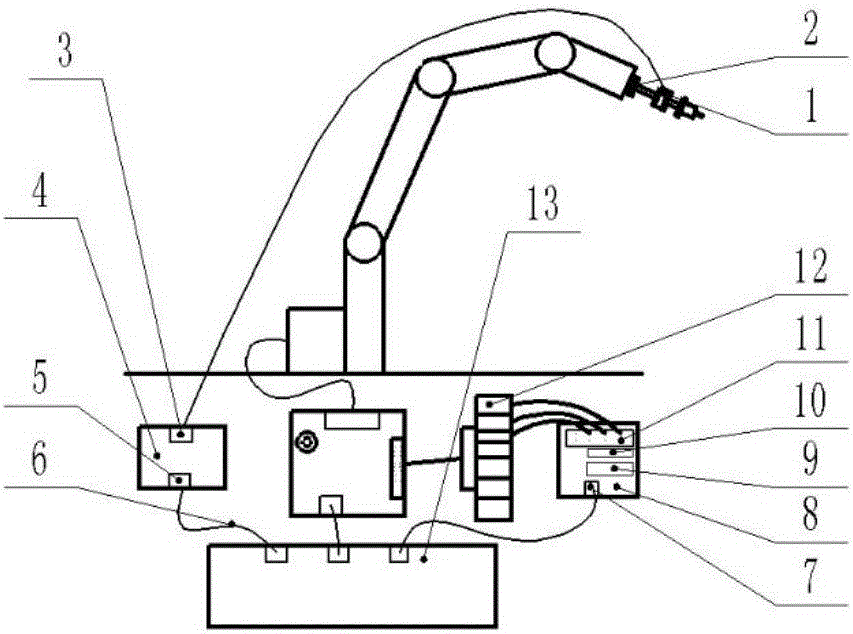

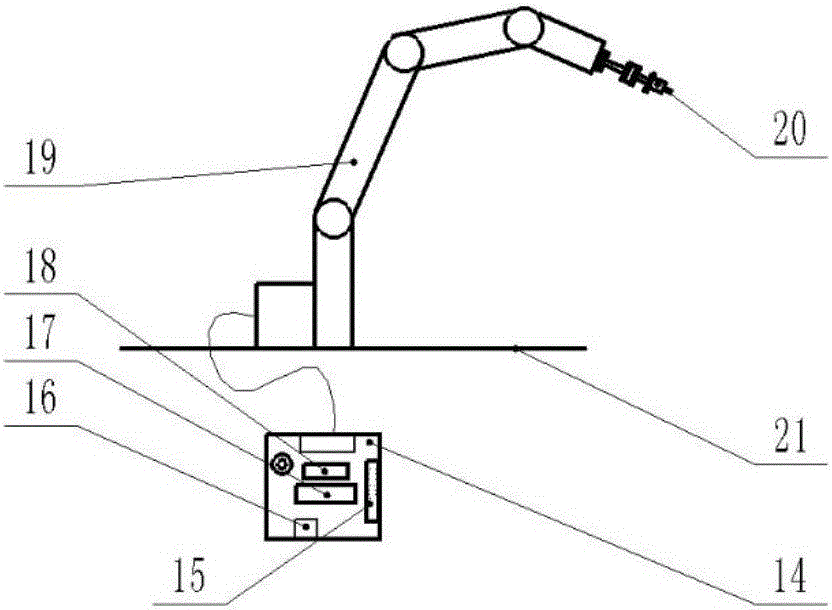

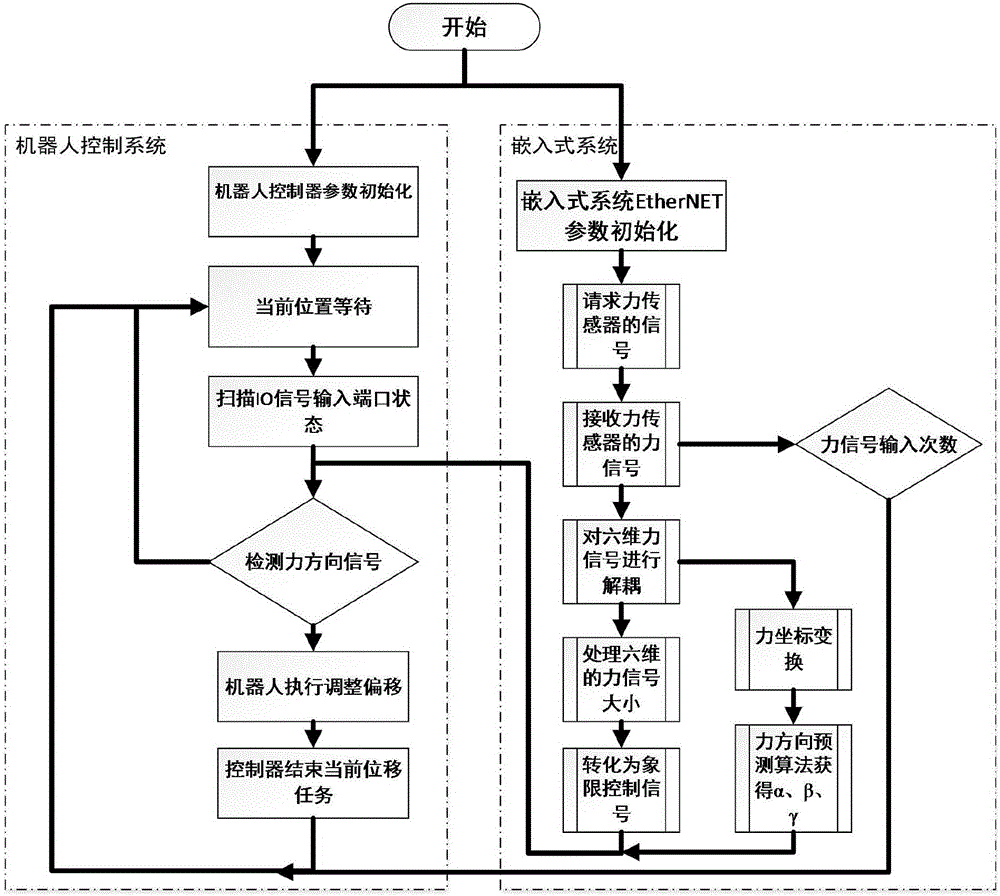

[0022] like Figure 1-4 As shown, firstly, the six-axis industrial robot controller (14) and the linux-based embedded control system Raspberry Pi (8) complete the parameter initialization, and the circular load unit (1) detects the force at the end of the robot, and then Send to the data storage box (4) through the force signal data input interface (3) for dynamic storage, and then connect the router (13) through the force signal data output interface (5) and Ethernet communication network cable (6), at the same time, the data The storage box (4) will be given an IP address.

[0023]Secondly, the force signal enters the embedded control system raspberry pie (8) based on linux from the raspberry pie Ethernet input interface (7) after passing through the router (13) port. In the system raspberry pie, the force signal will go through six steps. The signal processing process of the force signal decoupling unit (9) and the force coordinate transformation processing unit (10) furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com