An industrial control system for monitoring and controlling an automation plant

An industrial control system, monitoring automation technology, applied in general control system, comprehensive factory control, comprehensive factory control, etc., can solve problems such as addition, and achieve the effect of simple interaction and flexible interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments described below relate to the improvement of an industrial control system in the form of the well-known SCADA system, which can be used to monitor or control the technical processes of any automated factory. For example, an automated factory can be a factory used to manufacture or produce products. Furthermore, an automated factory can refer to a power plant, for example, a nuclear power plant or a power plant based on renewable energy.

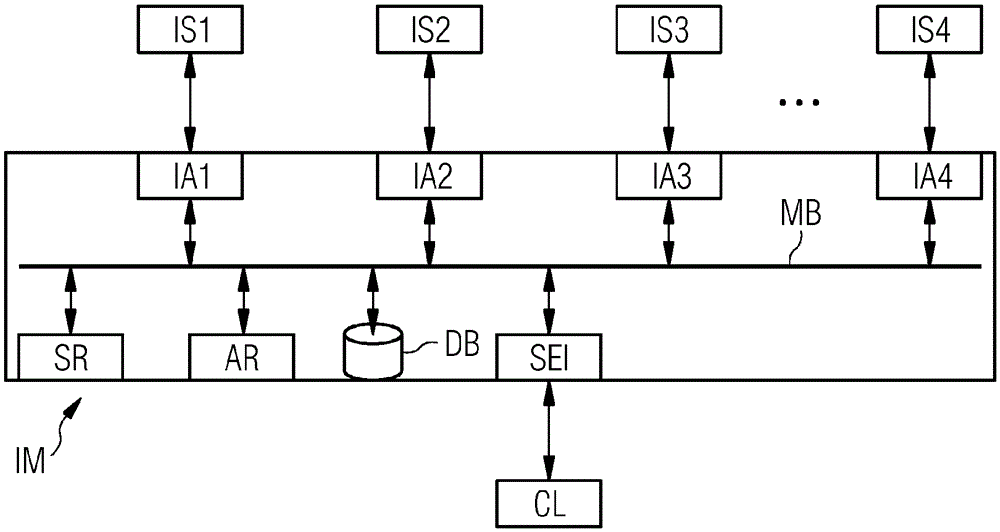

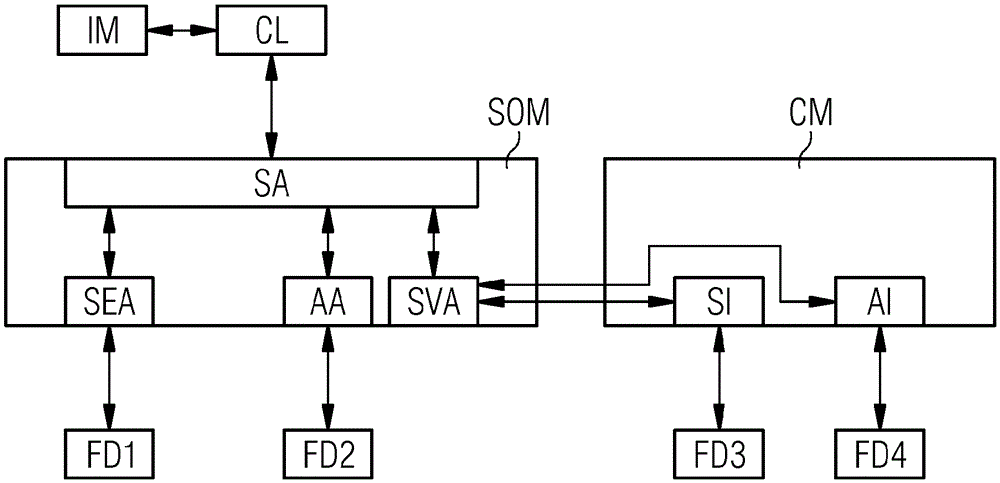

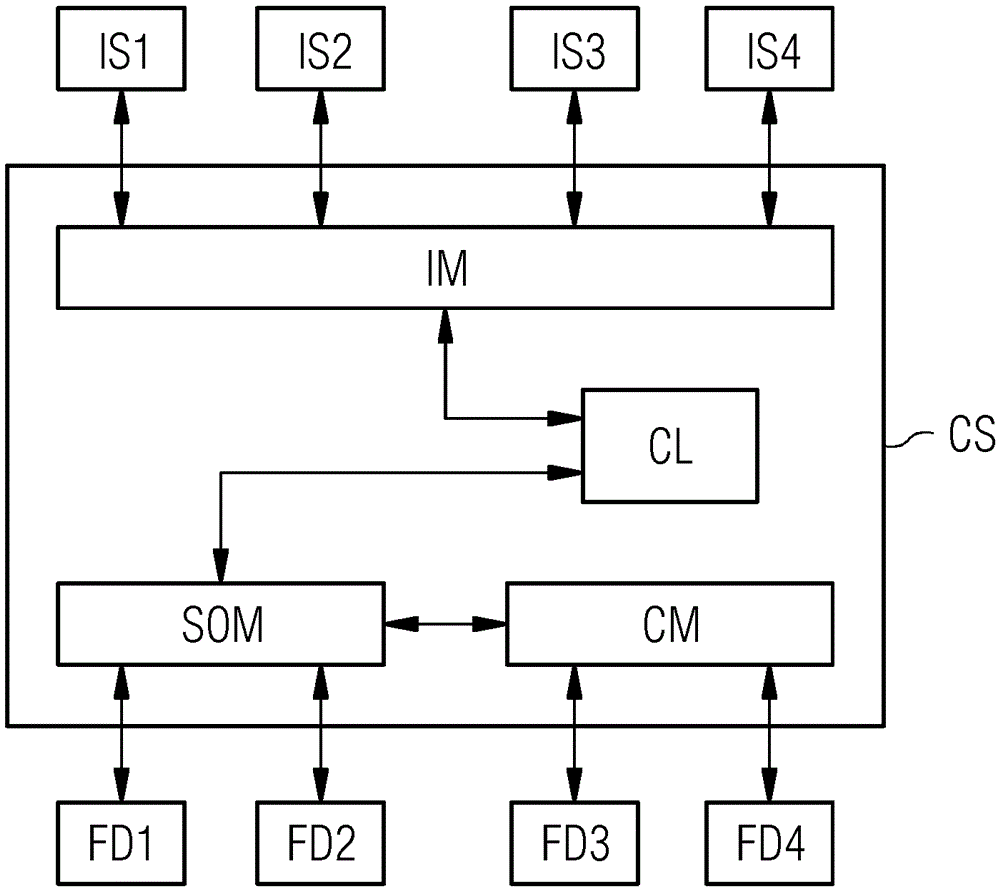

[0025] Such as figure 1 The SCADA control system shown in contains a SCADA core and a control logic CL communicating with a generic interface module IM and a service-oriented module SOM. hereinafter in Figure 1 to Figure 3 Communication between the components shown in is indicated by double arrows. The generic interface module IM couples the external information systems IS1, IS2, IS3 and IS4 to the control logic CL, and the service-oriented module SOM couples the plug-and-play field devices FD1 and FD2 directly to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com