Online detection bench for gearbox and detection method

A technology of gearbox and test bench, applied in vehicle testing, machine/structural component testing, machine gear/transmission mechanism testing, etc. It can solve problems such as high degree of automation, harsh working environment, and processing errors, and achieve the degree of automation High, the effect of ensuring personal and equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

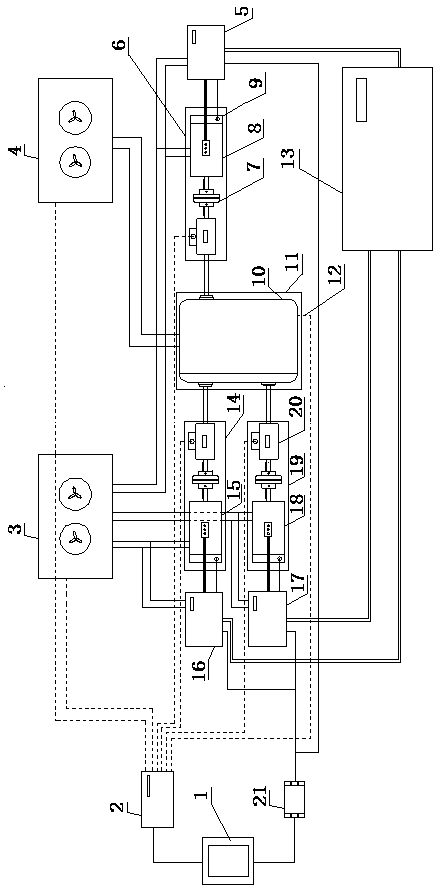

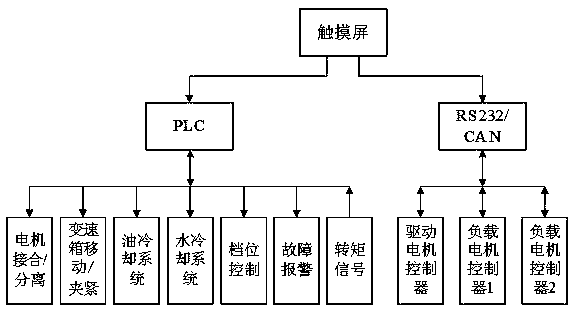

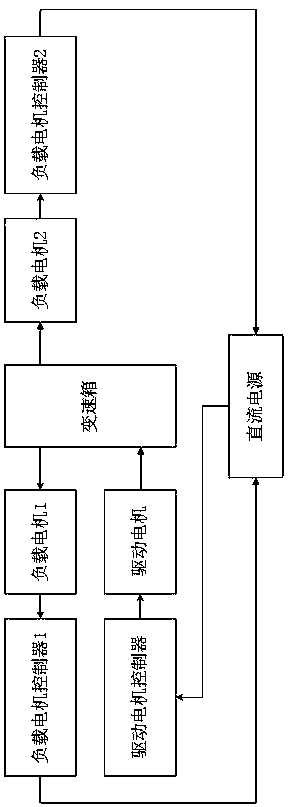

[0030] An on-line detection test bench for a gearbox, which consists of: a touch screen 1, the touch screen is connected to a programmable logic controller PLC2 and a RS232 / CAN communication converter 21 through Ethernet and RS232 serial lines respectively, and the programmable The logic controller PLC is respectively connected to the water cooling system 3 and the oil cooling system 4 through control lines, the oil cooling system is connected to the gearbox 10 through the oil cooling circuit, and the water cooling system is respectively controlled with the load motor through the water cooling circuit The controller II5 and the load motor II8 are connected, the load motor controller II is connected to the DC power supply 13 through the bus bar, and the DC power supply is connected to the drive motor controller 17 and the load motor controller I16 through the bus bar respectively;

[0031] The data acquisition and control system adopts a touch screen. The touch screen supports E...

Embodiment 2

[0033] According to the gearbox online detection test bench described in embodiment 1, the water cooling system is respectively connected with the load motor I15, the load motor II, the drive motor 18, the load motor controller I, the load motor controller II, and the drive motor controller connection, that is, the water cooling system is connected to 3 load motor controllers and 3 load motors respectively, and the RS232 / CAN communication converter is respectively connected to the load motor controller II and the drive motor through the CAN bus The controller and the load motor controller I are connected.

Embodiment 3

[0035]According to the gearbox online detection test bench described in embodiment 1, the gearbox is installed on the hydraulic platform I11, and the gear position control 12 is arranged below the hydraulic platform I and is connected with the programmable logic controller PLC. , the right side of the gearbox is connected to the torque sensor on the hydraulic platform II6, and the left side of the gearbox is respectively connected to the torque sensor on the hydraulic platform III14 and the torque sensor 20 on the hydraulic platform IV19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com