Pipeline working condition detection equipment, detection method and device and readable storage medium

A technology of detection equipment and detection method, which is applied in the fields of devices, readable storage media, detection methods, and pipeline condition detection equipment, and can solve problems such as inaccurate measurement of portable detection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

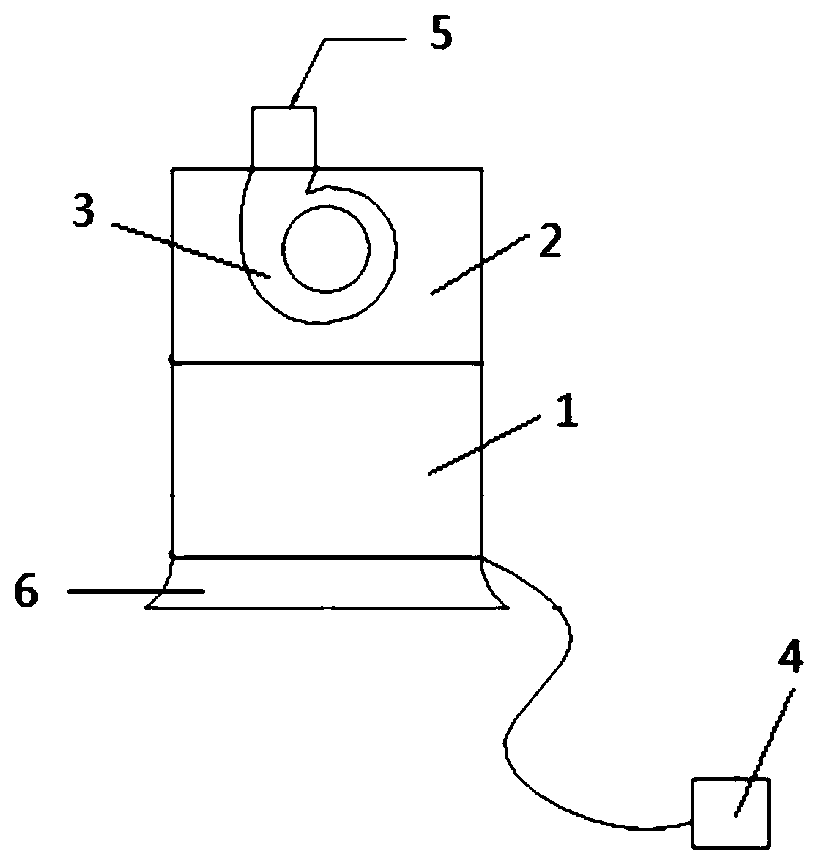

[0048] Embodiment 1 of the present invention provides a pipeline condition detection device, such as figure 1As shown, it includes a differential pressure flowmeter 1 and a processor 4. The differential pressure flowmeter 1 includes a diversion pipe section and a straight pipe section, the diversion pipe section is provided with a pressure sensor, and the straight pipe section is provided with a The first interface connected to the air inlet of the pipeline; the processor 4 is connected to the pressure sensor.

[0049] When the pipeline condition detection equipment is used to detect the pipeline to be tested, the gas enters the pipeline condition detection equipment through the diversion pipe section. In the embodiment of the invention, the straight pipe section may have different diameters according to the detected air volume. The first interface can be directly connected to the air inlet of the pipe to be tested, or can be connected through an adapter.

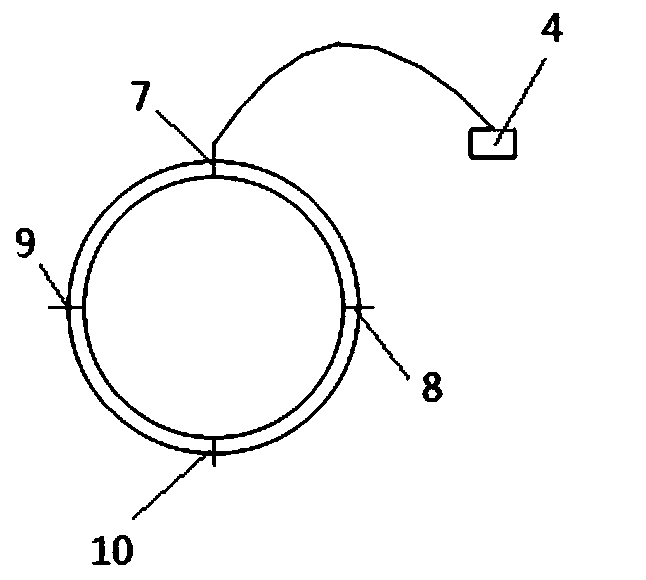

[0050] As a speci...

Embodiment 2

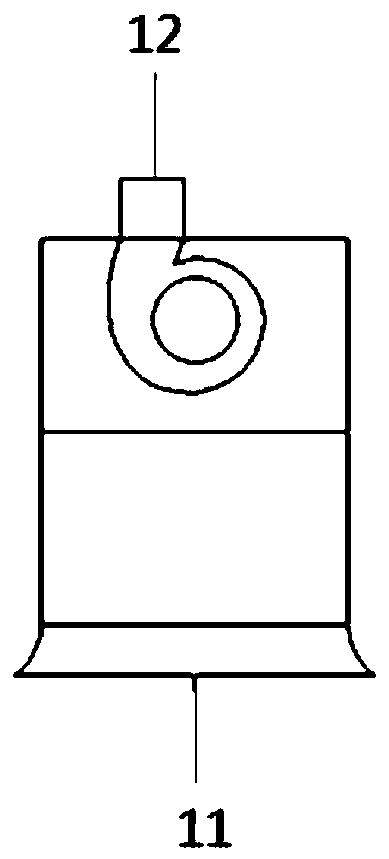

[0064] Embodiment 2 of the present invention provides a pipeline condition detection method, which is applied to pipeline condition detection equipment, the pipeline condition detection equipment includes a differential pressure flowmeter and a processor, and the differential pressure flowmeter includes a diversion pipe section and a A straight pipe section, the guide pipe section is provided with a pressure sensor, and the straight pipe section is provided with a first interface suitable for connecting with the air inlet of the pipeline to be tested. Such as Figure 4 Said, the pipeline working condition detection method of embodiment 2 of the present invention comprises the following steps:

[0065] S401: Obtain the pressure of the diversion pipe section of the differential pressure flowmeter.

[0066] The pressure of the draft pipe section is obtained through a pressure sensor in the draft pipe. As a specific implementation manner, after the fan is started, the pressure o...

Embodiment 3

[0097] Embodiment 3 of the present invention provides a pipeline condition detection device, which is applied to pipeline condition detection equipment. The pipeline condition detection equipment includes a differential pressure flowmeter and a processor. The differential pressure flowmeter includes a diversion pipe section and a A straight pipe section, the guide pipe section is provided with a pressure sensor, and the straight pipe section is provided with a first interface suitable for connecting with the air inlet of the pipeline to be tested. Such as Figure 5 As mentioned above, the pipeline condition detection device according to Embodiment 3 of the present invention includes an acquisition module 50 , a first processor 52 and a second processor 54 .

[0098] Specifically, the obtaining module 50 is configured to obtain the pressure of the guide pipe section of the differential pressure flowmeter.

[0099] The first processor 52 is configured to calculate the gas flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com